MOF-based cotton cloth immobilized polyacid catalytic material as well as preparation method and application thereof

A technology of polyacid catalysis and acid catalyst, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

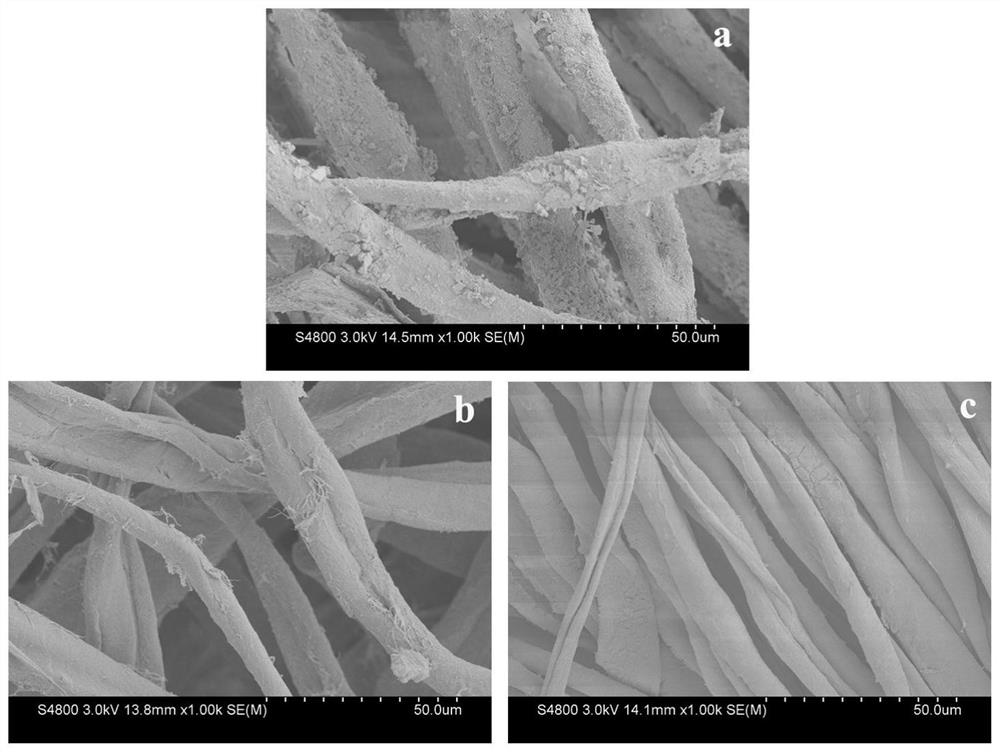

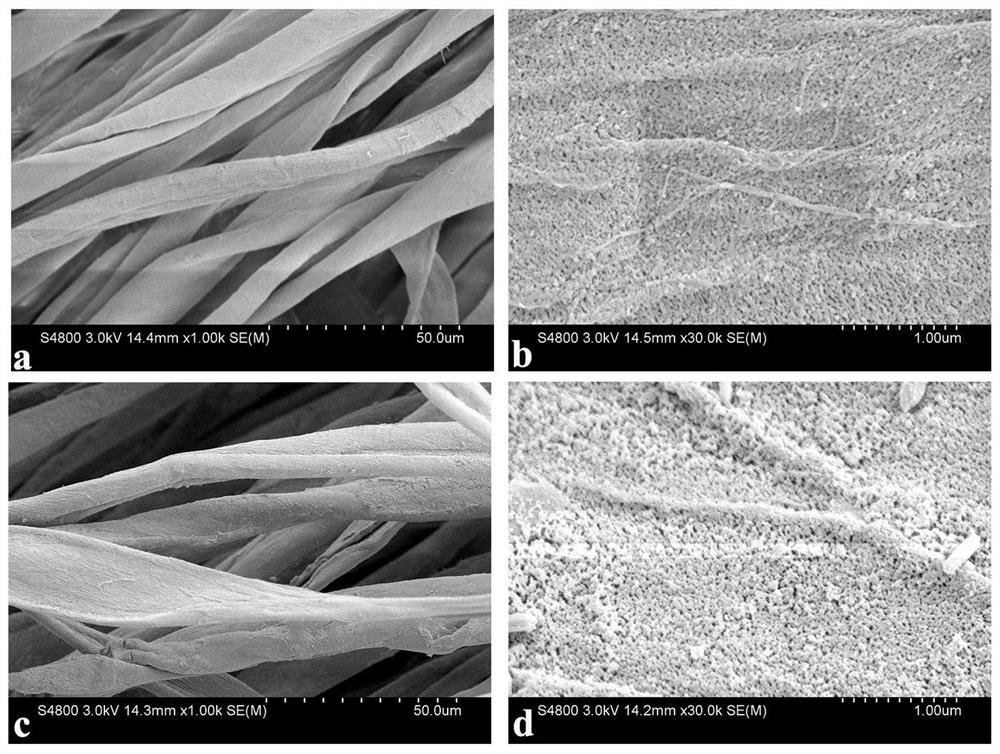

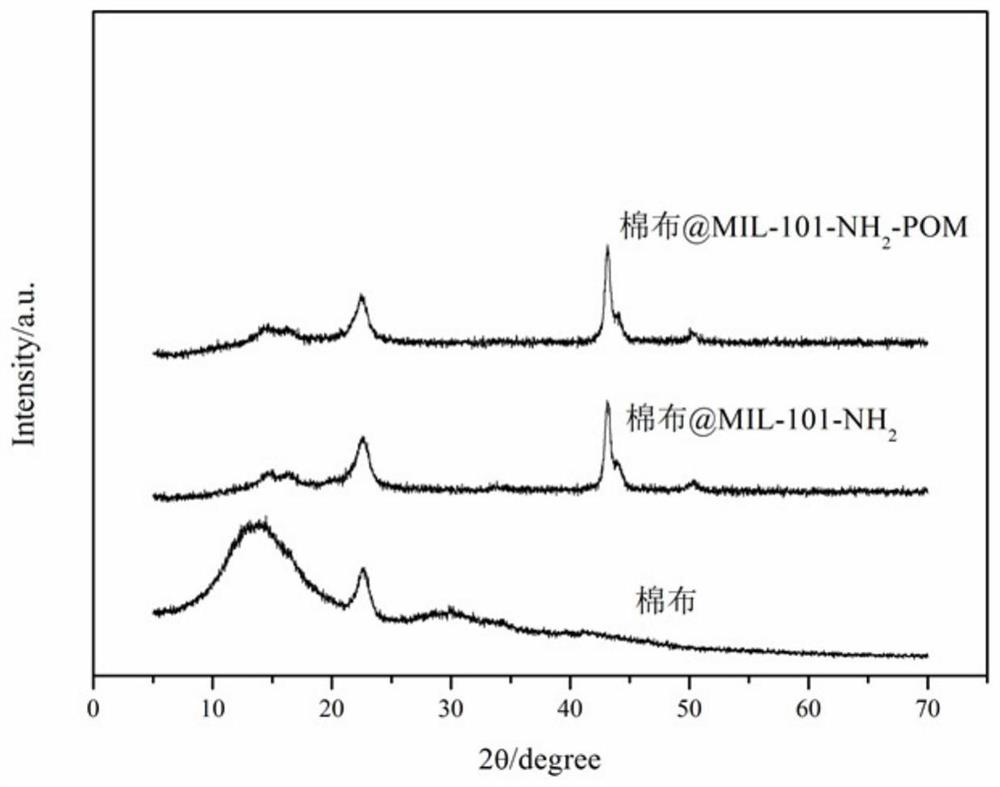

[0038] The preparation method of MOF-based cotton cloth immobilized multi-acid catalytic material comprises the following steps:

[0039] Step 1, pretreat the cotton cloth. The pretreatment process is as follows: soak 2 pieces of cotton cloth with a size of 5cm×5cm in 100mL of a mixed solution of water and isopropanol with a volume ratio of 1:4, and stir for 30min. And add 10mL of sodium hydroxide aqueous solution with a mass fraction of 25% at a rate of 2mL / min, stir at 30°C for 1h, then add 4.9g of sodium chloroacetate, stir at 45°C for 3h, take out the cotton cloth, and wash with methanol Rinse 5 times and dry in an oven at 50°C to obtain cotton cloth for use.

[0040] Step 2, using the cotton cloth to be used to prepare MOF-based cotton cloth, specifically includes the following sub-steps:

[0041] (1) The specific preparation process of cotton cloth @MIL-101 is as follows:

[0042] Sub-step 2.1, respectively prepare a DMF solution of 40mmol / L terephthalic acid, a 40mmol...

Embodiment 2

[0057] The preparation method of MOF-based cotton cloth immobilized multi-acid catalytic material comprises the following steps:

[0058] Step 1, pretreat the cotton cloth. The pretreatment process is as follows: soak 2 pieces of cotton cloth with a size of 5cm×5cm in 100mL of a mixed solution of water and isopropanol with a volume ratio of 1:4, and stir for 30min. And add 10mL of sodium hydroxide aqueous solution with a mass fraction of 25% at a rate of 2mL / min, stir at 30°C for 1h, then add 4.9g of sodium chloroacetate, stir at 45°C for 3h, take out the cotton cloth, and wash with methanol Rinse 5 times and dry in an oven at 50°C to obtain cotton cloth for use.

[0059] Step 2, using the cotton cloth to be used to prepare MOF-based cotton cloth, specifically includes the following sub-steps:

[0060] (1) The specific preparation process of cotton cloth @MIL-101 is as follows:

[0061] Sub-step 2.1, respectively prepare a DMF solution of 40mmol / L terephthalic acid, a 40mmol...

Embodiment 3

[0076] The preparation method of MOF-based cotton cloth immobilized multi-acid catalytic material comprises the following steps:

[0077]Step 1, pretreat the cotton cloth. The pretreatment process is as follows: soak 2 pieces of cotton cloth with a size of 5cm×5cm in 100mL of a mixed solution of water and isopropanol with a volume ratio of 1:4, and stir for 30min. And add 10mL of sodium hydroxide aqueous solution with a mass fraction of 25% at a rate of 2mL / min, stir at 30°C for 1h, then add 4.9g of sodium chloroacetate, stir at 45°C for 3h, take out the cotton cloth, and wash with methanol Rinse 5 times and dry in an oven at 50°C to obtain cotton cloth for use.

[0078] Step 2, using the cotton cloth to be used to prepare MOF-based cotton cloth, specifically includes the following sub-steps:

[0079] (1) The specific preparation process of cotton cloth @MIL-101 is as follows:

[0080] Sub-step 2.1, respectively prepare a DMF solution of 40mmol / L terephthalic acid, a 40mmol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com