A preparation method of titanium dioxide/13X molecular sieves compound materials used for treating dyestuff waste water

A technology for composite materials and dye wastewater, applied in the field of preparation of TiO2/13X molecular sieve composite materials, can solve the problems of secondary pollution adsorbent and coagulant regeneration can not be reasonably solved, the utilization rate of sunlight is not high, light-generated space The problem of easy recombination of holes and other problems, to achieve the effect of rich micropores, improved degradation efficiency, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

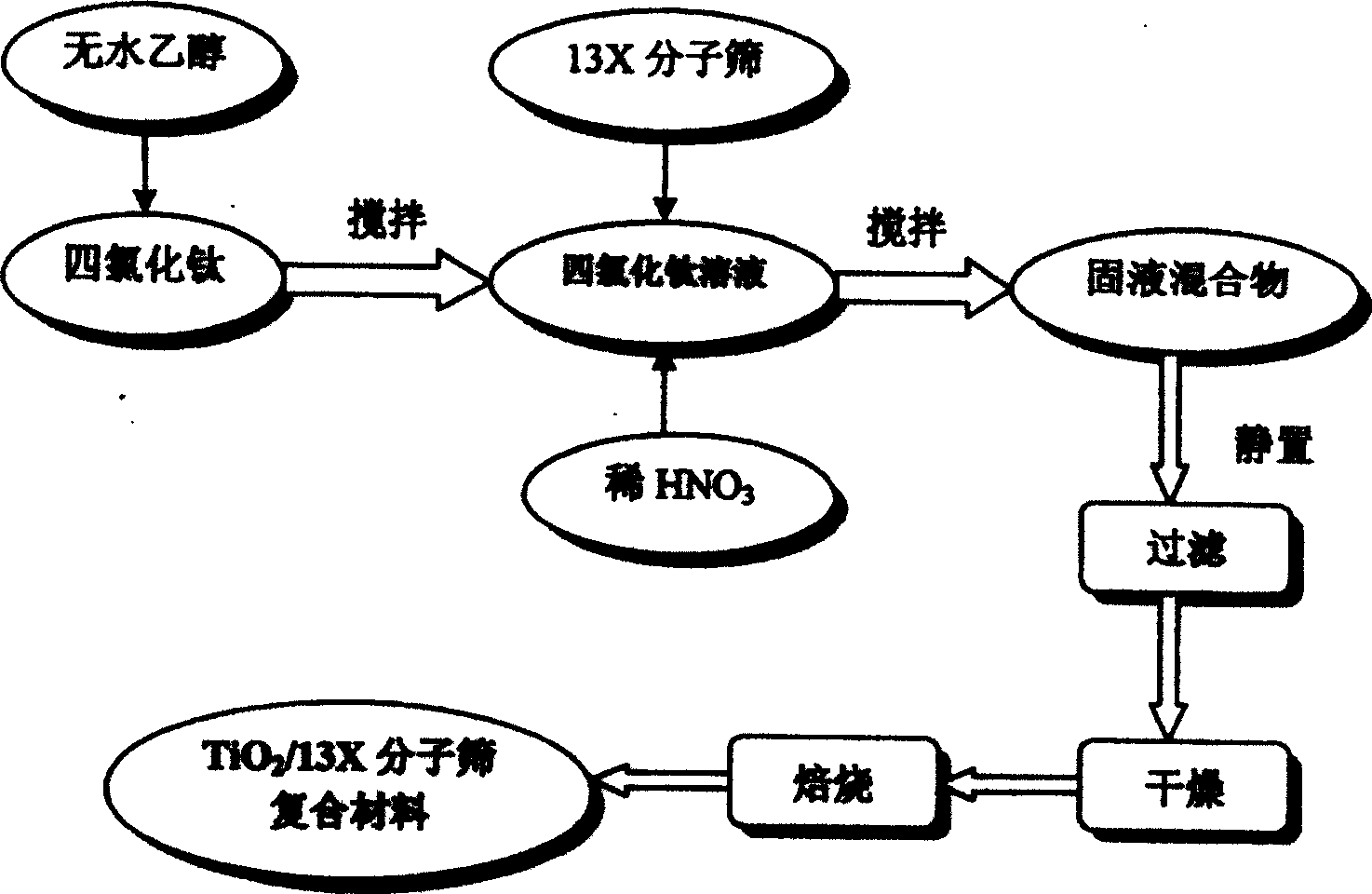

Method used

Image

Examples

Embodiment 1

[0023] 1. Measure 8ml of titanium tetrachloride solution in a beaker filled with 40ml of absolute ethanol to make a titanium tetrachloride / absolute ethanol solution, and stir vigorously at a constant speed.

[0024] 2. Weigh 10g of 13X molecular sieve with a particle size of 100 mesh, add it into a beaker filled with titanium tetrachloride solution, and stir vigorously at a constant speed for 3 hours.

[0025] 3. Then add dilute HNO dropwise into the beaker 3 Solution 10ml, stir for 2-3min, slowly add about 3ml of deionized water, stop stirring.

[0026] 4. After airtight aging at room temperature for 48 hours, the vacuum pump is used for suction filtration, and the filtrate is washed several times with absolute ethanol and deionized water.

[0027] 5. Put the filtered sample into a constant temperature blast drying oven, adjust the temperature to 110°C, and dry for 3 hours.

[0028] 6. Put the dried sample into a muffle furnace and bake it at 200°C for 4h.

[0029] 7. Get Ti...

Embodiment 2

[0031] 1. Measure 6ml of titanium tetrachloride solution in a beaker filled with 35ml of absolute ethanol to make a titanium tetrachloride / absolute ethanol solution, and stir vigorously at a constant speed.

[0032] 2. Weigh 10g of 13X molecular sieve with a particle size of about 100 mesh, add it into a beaker filled with titanium tetrachloride solution, and stir vigorously at a constant speed for 2 hours.

[0033] 3. Then add dilute HNO dropwise into the beaker 3 Solution 5ml, stir for 2-3min, slowly add about 2ml of deionized water, stop stirring.

[0034] 4. After airtight aging at room temperature for 40 hours, the vacuum pump is used for suction filtration, and the filtrate is washed several times with absolute ethanol and deionized water.

[0035] 5. Put the filtered sample into a constant temperature blast drying oven, adjust the temperature to 110°C, and dry for 2 hours.

[0036] 6. Put the dried sample into a muffle furnace and bake it at 200°C for 4h.

[0037] 7....

Embodiment 3

[0039] 1. Measure 10ml of titanium tetrachloride solution in a beaker filled with 45ml of absolute ethanol to make a titanium tetrachloride / absolute ethanol solution, and stir vigorously at a constant speed.

[0040] 2. Weigh 10 g of 13X molecular sieve with a particle size of 80 mesh, add it to a beaker containing a titanium tetrachloride solution, and stir vigorously at a constant speed for 3 hours.

[0041] 3. Then add dilute HNO dropwise into the beaker 3 Solution 10ml, stir for 2-3min, slowly add about 5ml of deionized water, stop stirring.

[0042] 4. After airtight aging at room temperature for 48 hours, the vacuum pump is used for suction filtration, and the filtrate is washed several times with absolute ethanol and deionized water.

[0043] 5. Put the filtered sample into a constant temperature blast drying oven, adjust the temperature to 110°C, and dry for 3 hours.

[0044] 6. Put the dried sample into a muffle furnace and bake it at 200°C for 4h.

[0045] 7. Get ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com