Solid catalyst for process of preparing ethylene glycol by hydrolyzing ethylene carbonate and preparation method thereof

A solid catalyst, ethylene carbonate technology, applied in physical/chemical process catalysts, hydrolysis preparation, chemical instruments and methods, etc., can solve the problems of difficult catalyst recovery and high cost, achieve long life, reduce reaction costs, and simple operation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

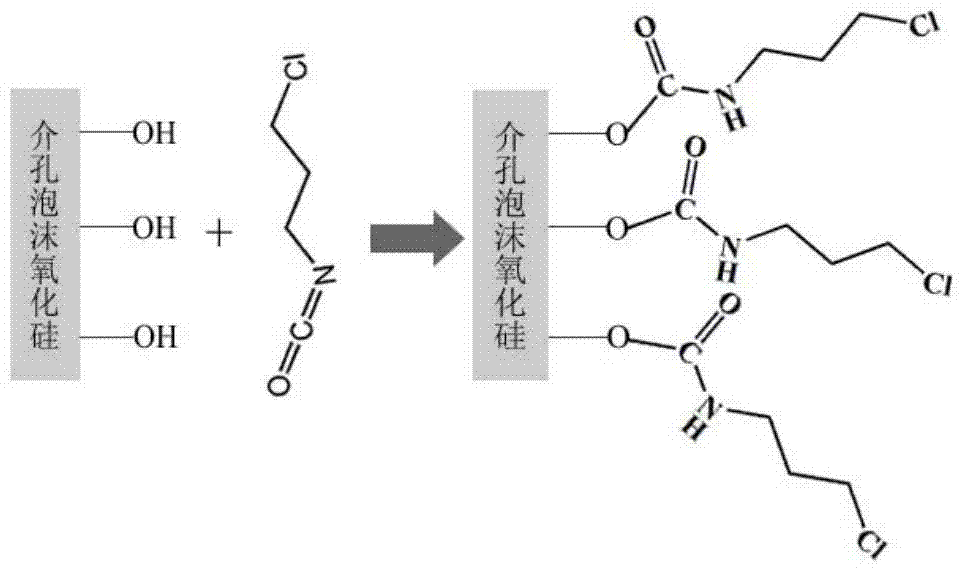

[0031] Add acetonitrile, mesoporous foamed silica and 3-chloropropyl isocyanate in sequence in a round bottom flask, wherein the mass ratio of mesoporous foamed silica to acetonitrile is 1:10; mesoporous foamed silica and 3-chloropropyl isocyanate The mass ratio is 8:1; after reacting at room temperature for 8 hours, the mesoporous foamed silicon oxide with surface hydroxyl esterification is obtained.

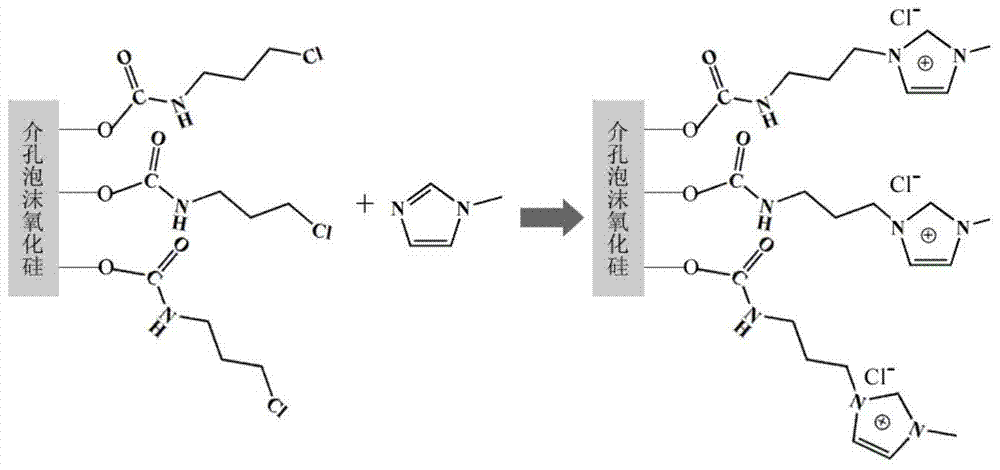

[0032] After filtering, washing and drying, put the solid obtained in the above process into a round bottom flask, then add toluene and 1-methylimidazole in sequence, wherein the mass ratio of solid to toluene is 1:10, and the solid to 1-methylimidazole The mass ratio is 5:1, and heated to 80°C for 6 hours with magnetic stirring to obtain a solid catalyst, denoted as Cat1.

Embodiment 2

[0034] Add acetonitrile, mesoporous foamed silica and 3-chloropropyl isocyanate in sequence in a round bottom flask, wherein the mass ratio of mesoporous foamed silica to acetonitrile is 1:20; mesoporous foamed silica and 3-chloropropyl isocyanate The mass ratio is 8:1; after reacting at room temperature for 6 hours, the mesoporous foamed silicon oxide with surface hydroxyl esterification is obtained.

[0035] After filtering, washing and drying, put the solid obtained in the above process into a round bottom flask, then add toluene and 1-methylimidazole in sequence, wherein the mass ratio of solid to toluene is 1:20, and the solid to 1-methylimidazole The mass ratio of the catalyst is 7:1, heated to 80°C with magnetic stirring for 8 hours, and the solid catalyst can be obtained, which is denoted as Cat2.

Embodiment 3

[0037] Add acetonitrile, mesoporous foamed silica and 3-chloropropyl isocyanate in sequence in a round bottom flask, wherein the mass ratio of mesoporous foamed silica to acetonitrile is 1:15; mesoporous foamed silica and 3-chloropropyl isocyanate The mass ratio is 10:1; after reacting at room temperature for 8 hours, the mesoporous foamed silicon oxide with surface hydroxyl esterification is obtained.

[0038]After filtering, washing and drying, put the solid obtained in the above process into a round bottom flask, then add toluene and 1-methylimidazole in sequence, wherein the mass ratio of solid to toluene is 1:10, and the solid to 1-methylimidazole The mass ratio is 6:1, heated to 80°C with magnetic stirring for 8 hours to obtain a solid catalyst, denoted as Cat3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com