Preparation method of carbon nanotube reinforced hydroxyapatite composite material

A nano-hydroxyapatite and hydroxyapatite technology, applied in the field of composite materials, can solve the problems of difficult to disperse, difficult to form composite materials, biocompatibility, low bonding strength of wetted interfaces, etc., to avoid splitting, improve Wetting and interfacial bonding, the effect of improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

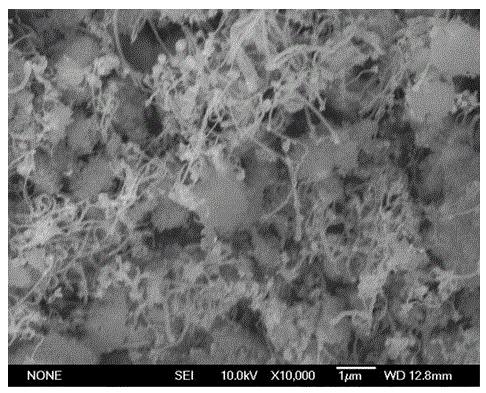

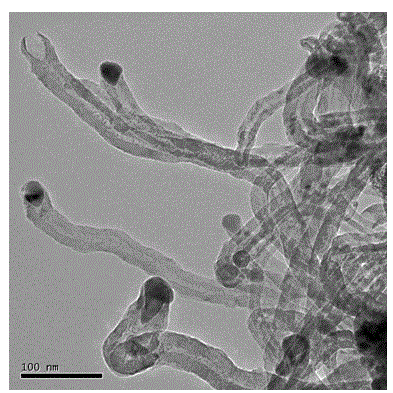

[0029] The first step is to prepare carbon nanotube-hydroxyapatite powder

[0030] According to the molar ratio of nickel carbonate: hydroxyapatite = 0.04:1 ratio, weigh the required amount of nickel carbonate and 10nm hydroxyapatite powder, mix, and then use a high-speed disperser to disperse 0.5 at a speed of 500r / min. h, use a planetary ball mill to mill at a speed of 800r / min for 1h, place the above-mentioned dispersed and ball-milled mixture in a quartz ark, and place the quartz ark in a constant temperature zone of a horizontal tube furnace at a flow rate of 100ml / min Introduce argon gas into the tube furnace and raise the temperature to 400°C, keep it warm for 1h, then close the argon gas, feed hydrogen gas into the tube furnace at a flow rate of 100ml / min, raise the temperature to 600°C and keep it for 1h, then close For hydrogen, a mixed gas with a volume ratio of argon:ethane=10:1 is continuously fed into the horizontal tube furnace at a flow rate of 660ml / min, and t...

Embodiment 2

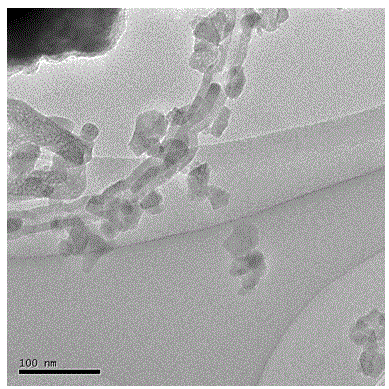

[0040] The first step is to prepare carbon nanotube-hydroxyapatite powder

[0041] According to the molar ratio of nickel carbonate: hydroxyapatite = 0.75:1, weigh the required amount of nickel carbonate and 50nm hydroxyapatite powder, mix, and then use a high-speed disperser to disperse 0.8 at a speed of 650r / min. h, use a planetary ball mill to mill at a speed of 900r / min for 1.5h, place the above-mentioned mixture after dispersion and ball milling in a quartz ark, place the quartz ark in a constant temperature zone of a horizontal tube furnace, and heat it at a temperature of 110ml / min. The flow rate is to feed argon into the tube furnace and raise the temperature to 450°C, keep it warm for 1.5h, then turn off the argon, feed hydrogen into the tube furnace at a flow rate of 110ml / min, raise the temperature to 900°C and keep it for 1.5h , then close the hydrogen, the volume ratio is argon: ethane = 12:1 mixed gas with a flow rate of 780ml / min continue to pass into the horizo...

Embodiment 3

[0047] The first step is to prepare carbon nanotube-hydroxyapatite powder

[0048] The molar ratio is the ratio of nickel carbonate: hydroxyapatite=1.50:1, weigh the required amount of nickel carbonate and 100nm hydroxyapatite powder, mix, and then use a high-speed disperser to disperse at a speed of 800r / min for 1h , use a planetary ball mill to mill for 2 hours at a speed of 1000r / min, place the above-mentioned dispersed and ball-milled mixture in a quartz ark, place the quartz ark in a constant temperature zone of a horizontal tube furnace, and flow to Introduce argon into the tube furnace and raise the temperature to 500°C, keep it warm for 2 hours, then turn off the argon, pass hydrogen into the tube furnace at a flow rate of 120ml / min, raise the temperature to 1200°C and keep it for 2 hours, then turn off the hydrogen , the volume ratio of argon: ethane=15:1 mixed gas is continuously passed into the horizontal tube furnace at a flow rate of 960ml / min, and the catalytic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com