Frame-shaped spiral winding plastic pipe as well as production equipment and production process thereof

A technology of spiral winding and plastic pipes, applied in the direction of mechanical equipment, pipes, rigid pipes, etc., can solve the problems of heavy pipe weight, low manufacturing cost, high production cost, etc., achieve strong system adaptability, save material costs, and meet long-term requirements The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

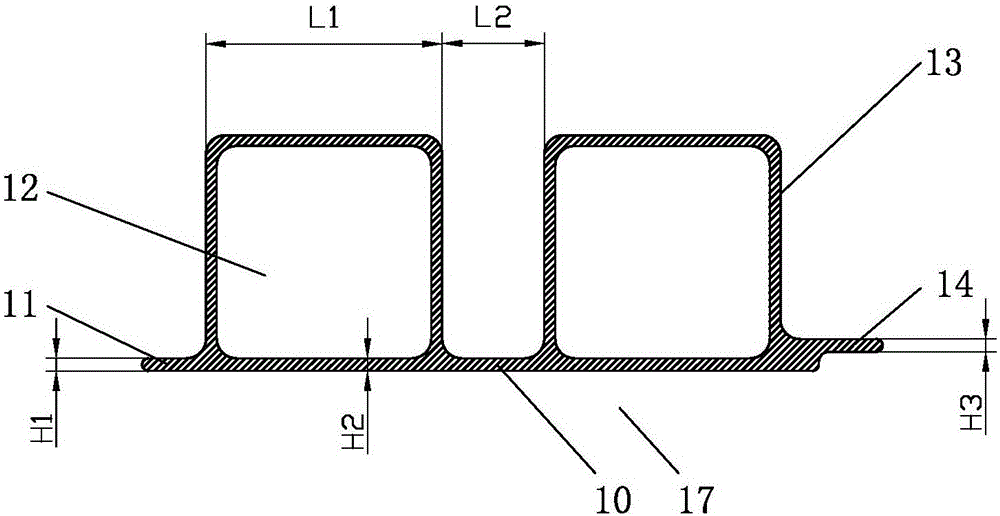

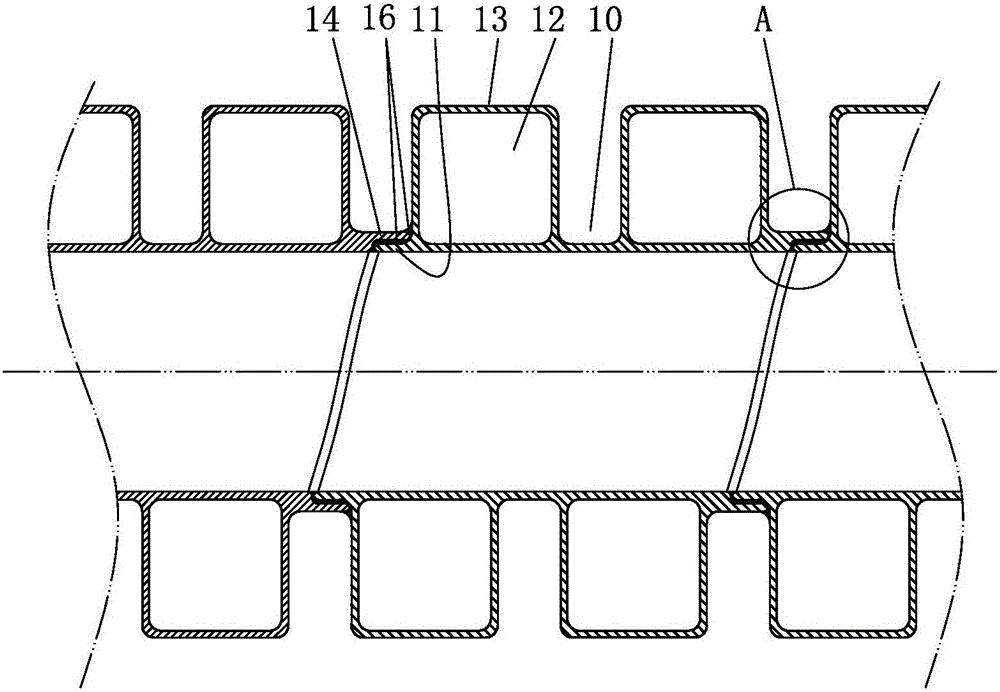

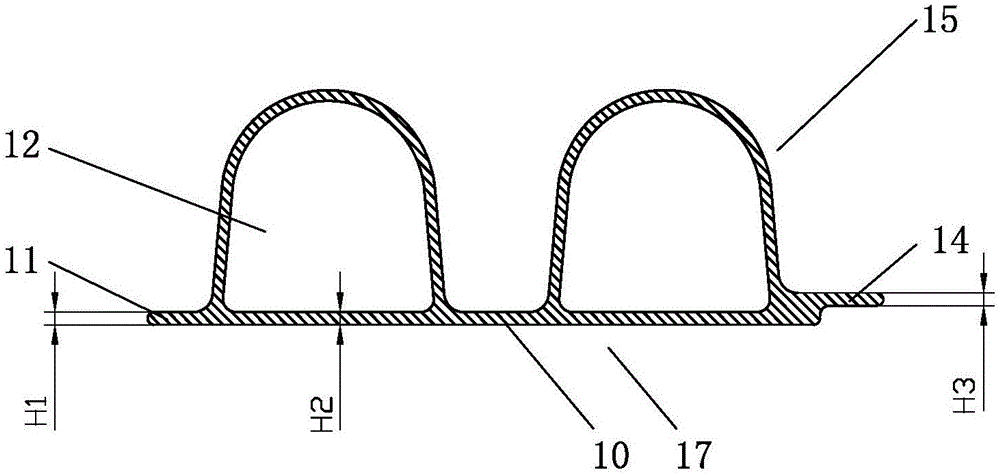

[0038] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 11 :

[0039] Frame-shaped spirally wound plastic tube, the outer surface of the plastic belt 10 is formed with more than one hollow rectangular tube 13 or hollow arched tube 15 with a smooth transition on the outer surface of the plastic belt 10, and one side of the plastic belt 10 is provided with a connecting edge 11 , the upper surface of the other side extends outwards with a buckle edge 14 to form a strip-shaped profile 17, and the buckle-joint edge 14 after the strip-shaped profile 17 is spirally wound is fastened to the connecting edge 11 on one side, and the buckle-joint edge 14 and The junction of the connecting sides 11 is hot-melt bonded by hot melt adhesive 16 to form a frame-shaped spirally wound plastic tube with a hollow spiral rectangular tube 13 or an arched tube 15 on the outer surface and a smooth inner sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com