Manufacturing method for controllable focal length liquid lens array

A technology of a liquid lens and a manufacturing method, which is applied in the directions of lenses, optics, instruments, etc., can solve the problems affecting the entrance pupil parameters of microlenses and the limited use range, and achieve the effects of excellent imaging quality, simple manufacturing method and controllable focal length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

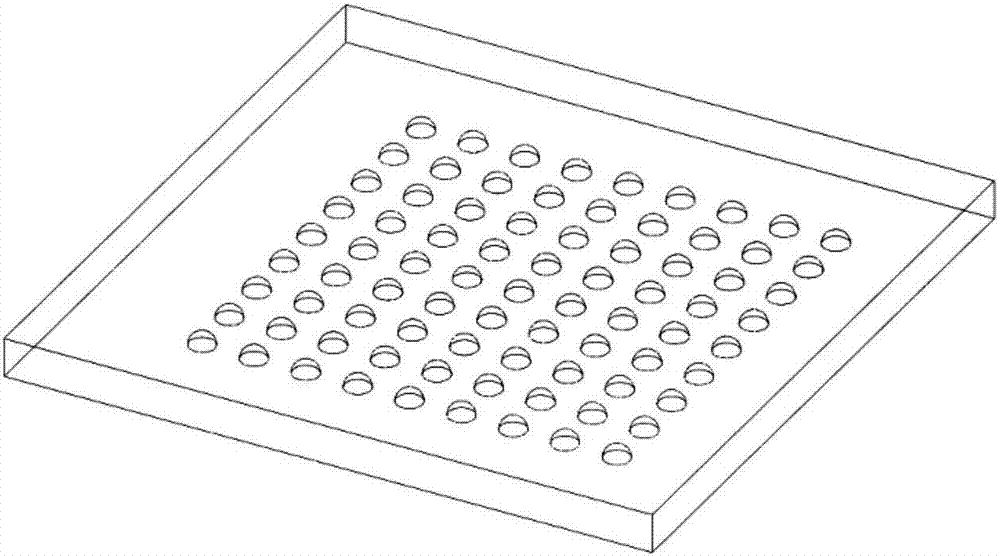

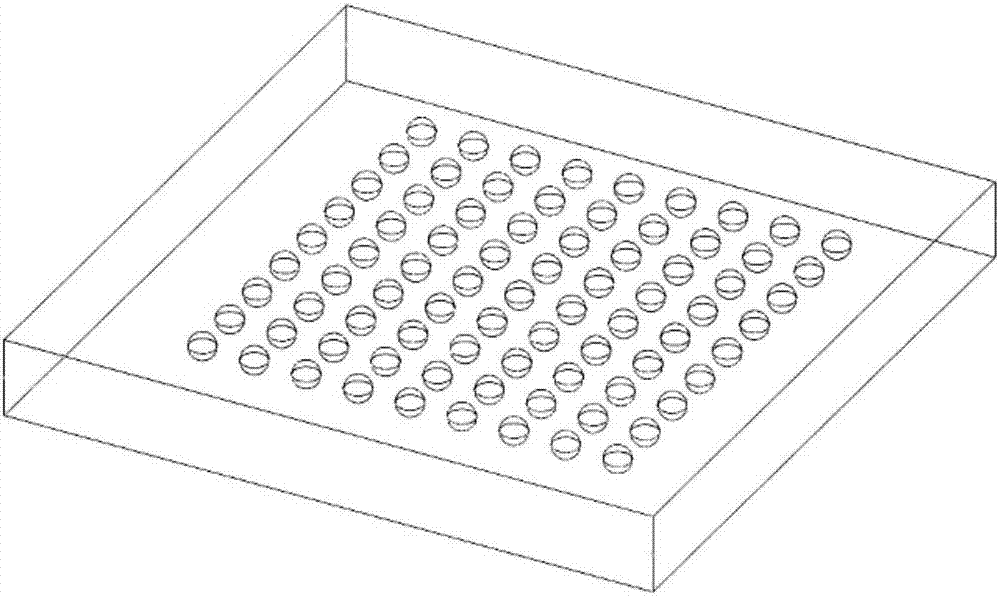

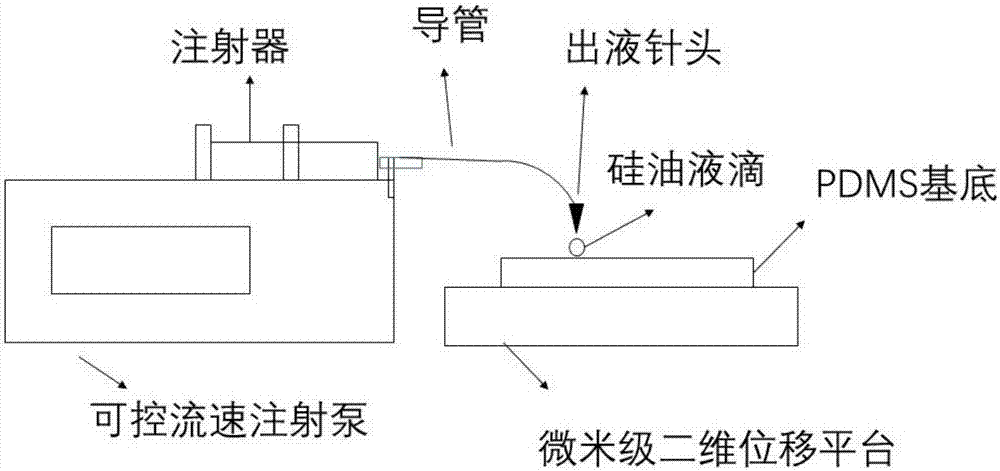

[0024] The embodiments of the present invention provide two methods for manufacturing arrays of liquid lenses with controllable focal lengths. The focal length of the liquid lenses is determined by the quality of the silicone oil dropped. The substrate for making the liquid lens array with controllable focal length is a silicone mixed liquid, which can be formed into an elastic solid by heating. By controlling the manufacturing temperature, the plano-convex or bi-convex shape of the lens can be controlled. Through the two-dimensional displacement platform, the number and direction of the array lens are controlled.

[0025] In the embodiment of the present invention, due to the difference in refractive index between silicone oil and silica gel, the light path will change when light enters the array lens to form a lens.

[0026] In the embodiment of the present invention, since the density of the silicone oil is higher than that of the silicone base liquid, after the silicone o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com