Ultraviolet-light-cured glass transparent ink and preparation method thereof

A technology of transparent ink and ultraviolet light, applied in the direction of ink, household appliances, application, etc., can solve the problem of poor performance of UV inkjet ink, and achieve the effect of fast curing, smooth and clear pattern edges, and good matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

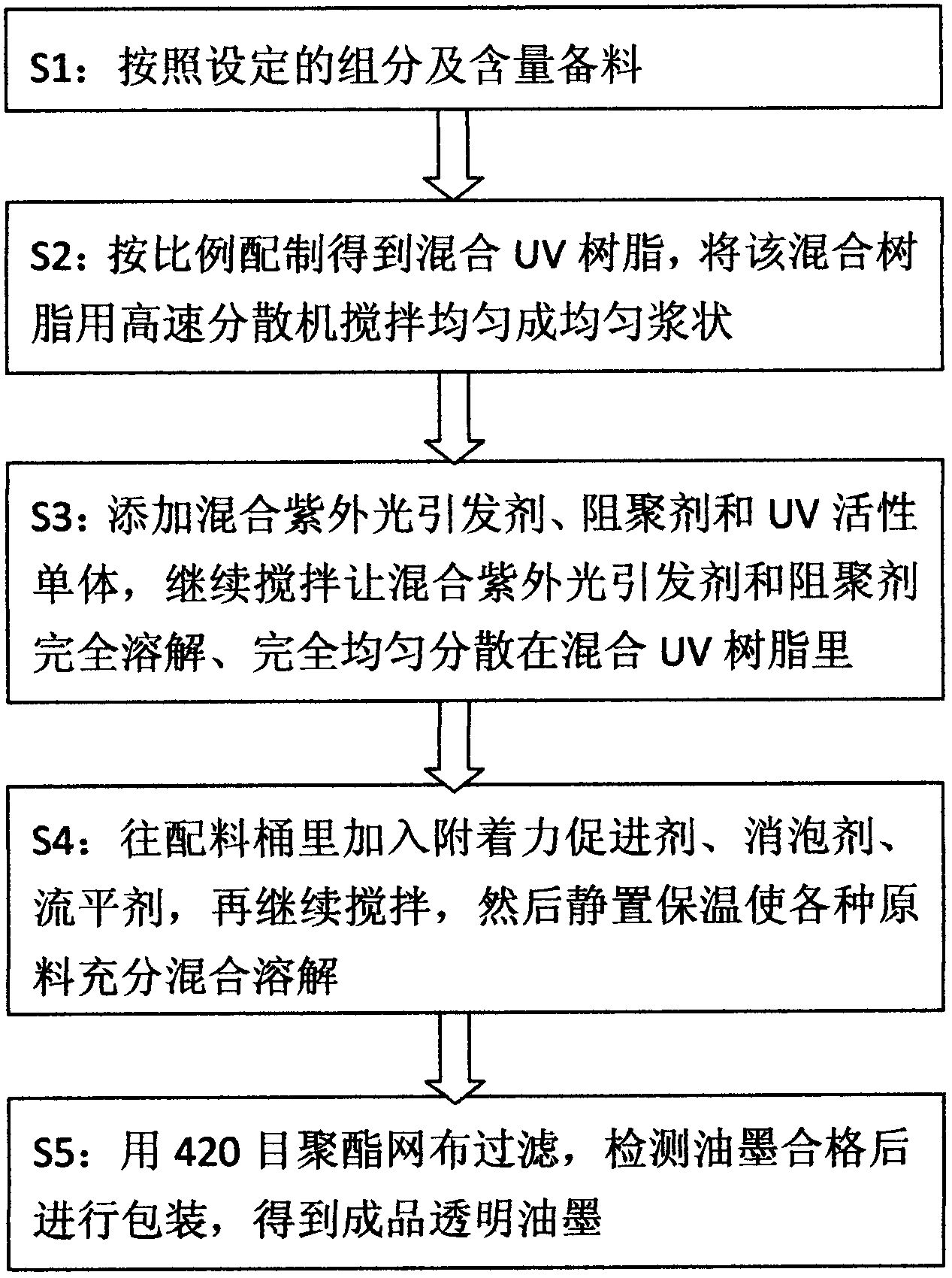

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments. It should be understood that these examples are only for illustrating the present invention and do not limit the scope of the present invention. At the same time, after reading the content taught by the present invention, those skilled in the art can adjust or optimize the formula of the present invention according to the actual situation.

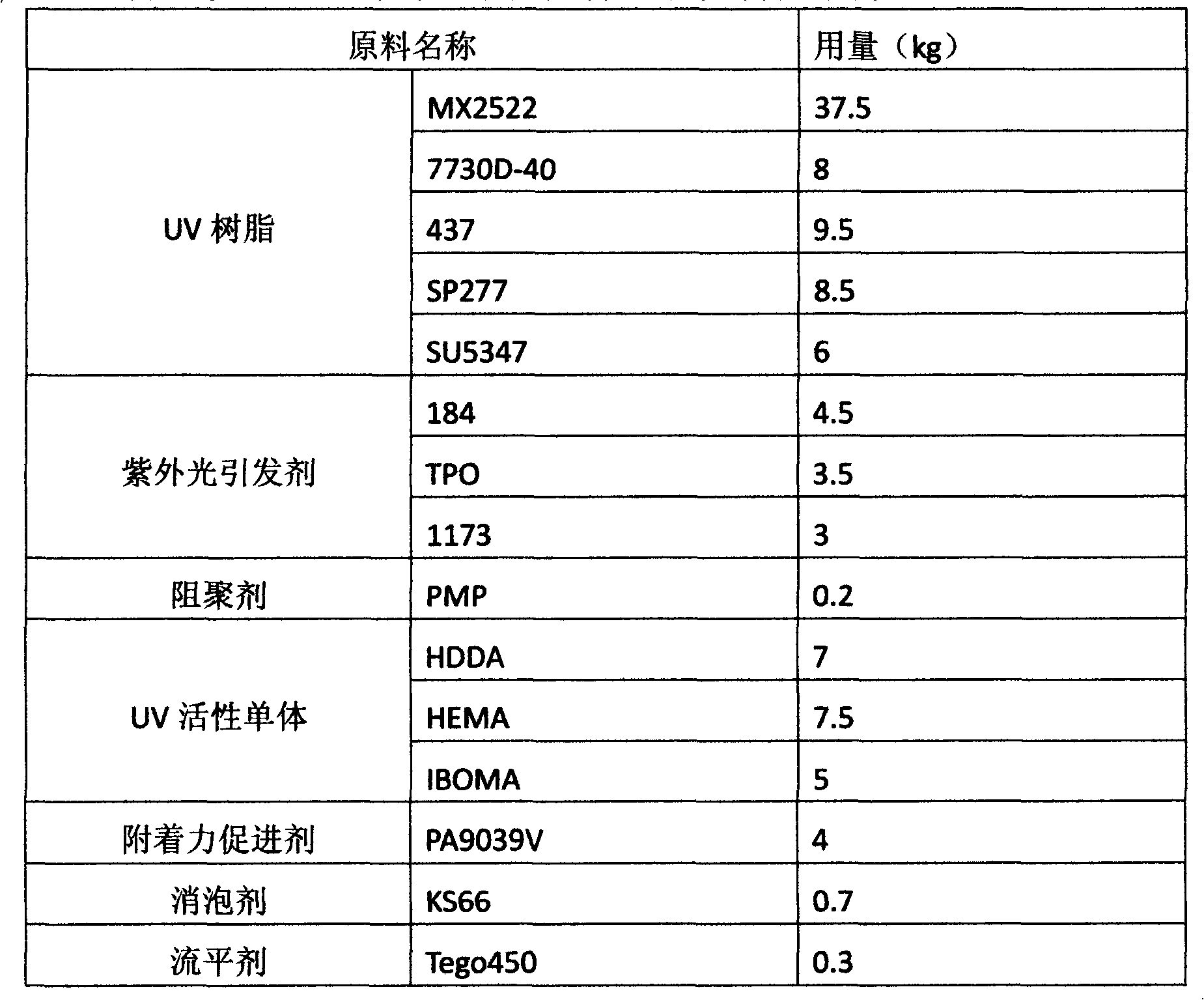

[0021] A UV curable glass transparent ink matched with UV inkjet painting of the present invention comprises the following components and content (wt%): 55-80% mixed UV resin, 5-10% mixed UV photoinitiator, 0.1- 0.5% polymerization inhibitor, 10-30% UV active monomer, 1-3% adhesion promoter, 0.5-1% defoamer and 0.2-0.8% leveling agent; the mixing UV resin is specially modified acrylic resin, special acrylate polymer, carboxylic acid modified polyester acrylate, aliphatic polyurethane diacrylate by weight ratio (10-18):(2-6):(3-8) : (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com