Preparation method of rubber vulcanization accelerator zinc dimethyl dithiocarbamate

A technology of zinc dimethyl dithiocarbamate and rubber vulcanization, applied in organic chemistry and other directions, can solve problems such as non-compliance with national environmental protection policies and energy-saving production requirements, low melting point of products, and difficult operation, and achieve excellent vulcanization performance, Short curing time and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

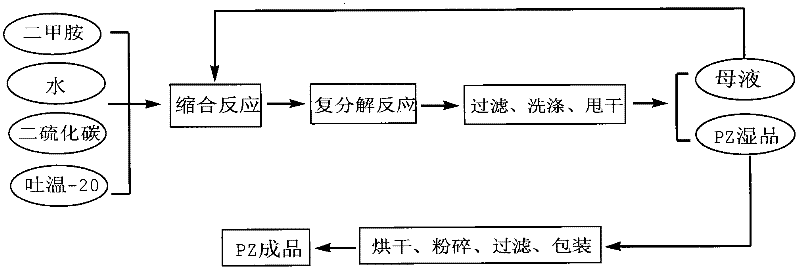

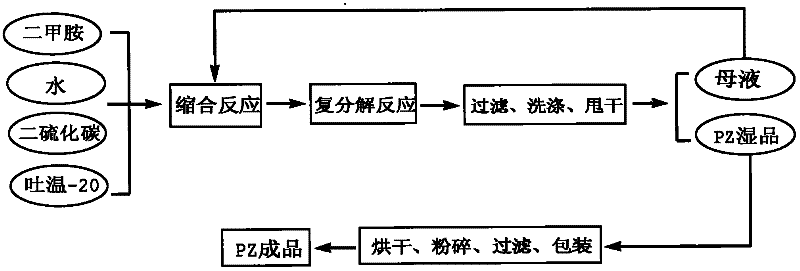

Method used

Image

Examples

Embodiment 1

[0026] The raw materials used and their stoichiometric molar ratios are dimethylamine: carbon disulfide: nonionic surfactant: zinc oxide=1: 0.95: 0.02: 0.52.

[0027] The process is as follows: add dimethylamine, non-ionic surfactant, and zinc oxide to the reaction kettle filled with pure water in sequence under stirring, and then add carbon disulfide liquid dropwise after stirring for 30 minutes. The dropping time is 2 hours, and the temperature is controlled at 21°C. After stirring for 1 hour, solid-liquid separation is carried out, the liquid is discarded, and the solid is dried, pulverized, sieved, and packaged. The yield of the obtained product is 94.8%, the initial melting point is 243.1° C., and the purity is 99.0%.

Embodiment 2

[0029] Wherein the raw materials used and their stoichiometric molar ratios are: dimethylamine: carbon disulfide: nonionic surfactant: zinc oxide=1: 1.1: 0.022: 0.55.

[0030] The process is as follows: add dimethylamine, non-ionic surfactant, and zinc oxide to the reaction kettle filled with pure water in turn under stirring, and then add carbon disulfide liquid dropwise after stirring for 30 minutes. The dropping time is 2.3 hours, and the temperature is controlled. at 23°C. After stirring for 1 hour, solid-liquid separation is carried out, the liquid is discarded, and the solid is dried, pulverized, sieved, and packaged. The yield of the obtained product is 95.4%, the initial melting point is 243.6°C, and the purity is 99.3%.

Embodiment 3

[0032] Wherein, the raw materials used and their stoichiometric molar ratios are dimethylamine:carbon disulfide:nonionic surfactant:zinc oxide=1:1.2:0.025:0.58.

[0033] The process is as follows: add dimethylamine, non-ionic surfactant, and zinc oxide to the reaction kettle filled with pure water in a stirring state, and add carbon disulfide liquid dropwise after stirring for 30 minutes. The dropping time is 2.5 hours, and the temperature is controlled. at 24°C. After stirring for 1 hour, solid-liquid separation is carried out, the liquid is discarded, and the solid is dried, pulverized, sieved, and packaged. The yield of the obtained product is 95.3%, the initial melting point is 243.5° C., and the purity is 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com