Double-compacted parallel laid wire rope for telescopic boom

A technology of steel wire rope and parallel lay, which is applied in the field of steel wire rope to achieve the effect of strong wear resistance, improved wear resistance, and high breaking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

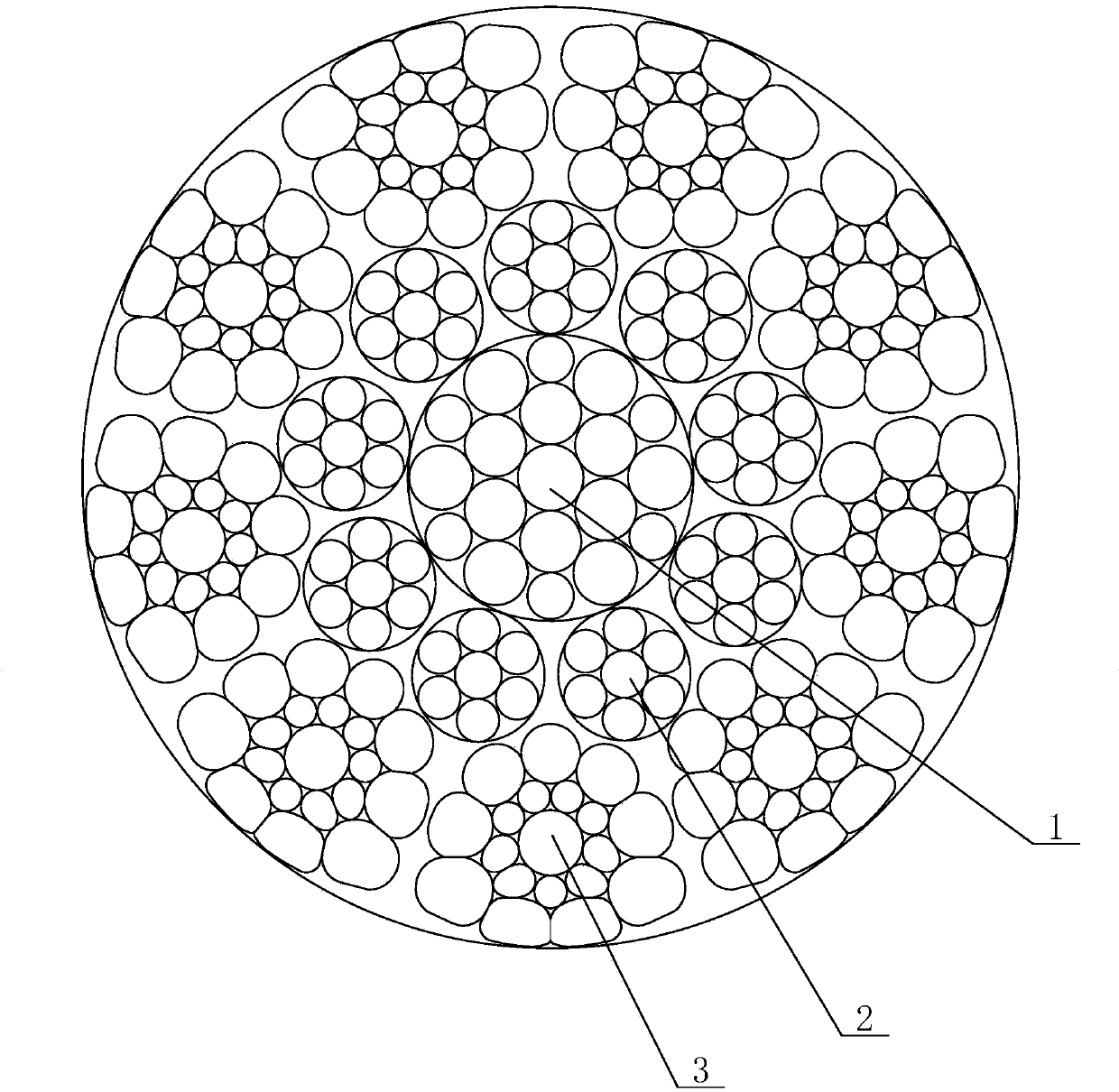

[0015] See figure 1 As shown, figure 1 It is a schematic cross-sectional structure diagram of a double-compacted parallel twisted steel wire rope for a telescopic arm according to the first embodiment of the present invention.

[0016] In this embodiment, a double compacted parallel twisted steel wire rope for a telescopic arm includes a central strand 1, nine inner strands 2 and nine outer strands 3, and the nine inner strands 2 are symmetrically wrapped in In addition to the central strand 1, the nine outer strands 3 are symmetrically twisted in the grooves on the surface of the inner strand 2. The steel wire rope is a compacted rope, and the inner strands of the rope are in surface contact with the strands. Strand 3 is a compacted strand, the steel wires in the strand are in surface contact, and the steel wire rope is a parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com