Rolling tool for axial external threads

An external thread and tool technology, applied in the field of axial external thread rolling tools, can solve problems such as affecting sealing performance and reliability, stagnant technical research, and process dispersion, etc., to ensure accuracy, good sealing effect, and extrusion resistance. Strong pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

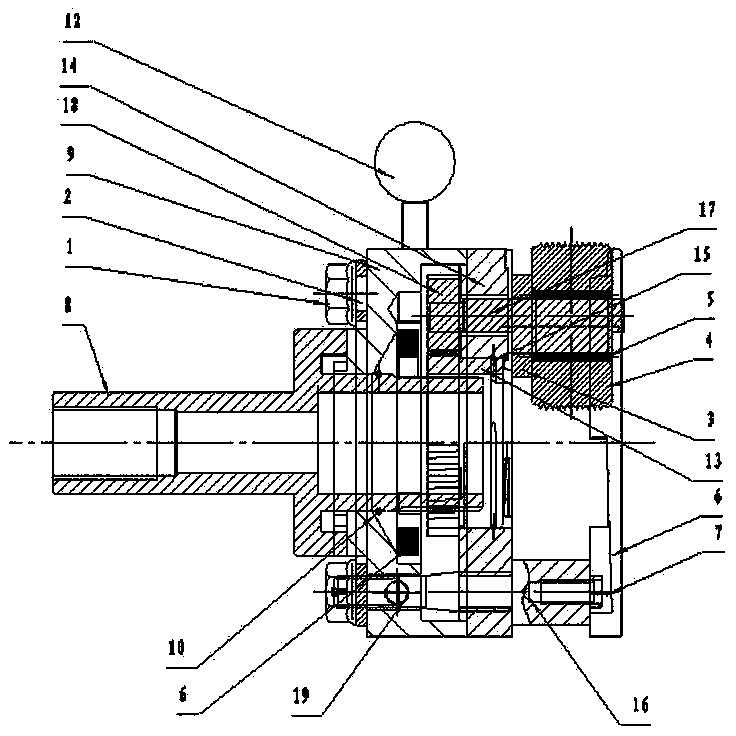

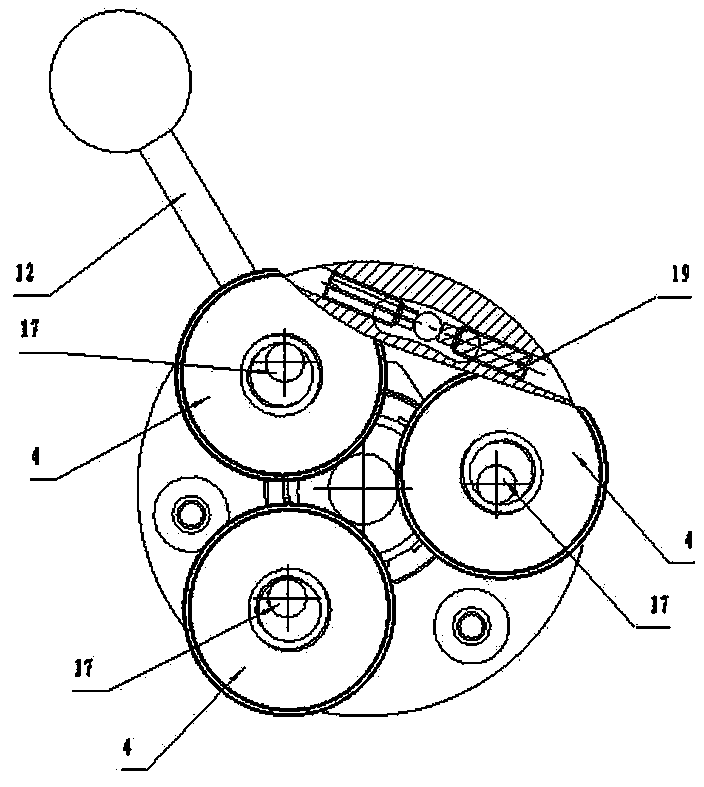

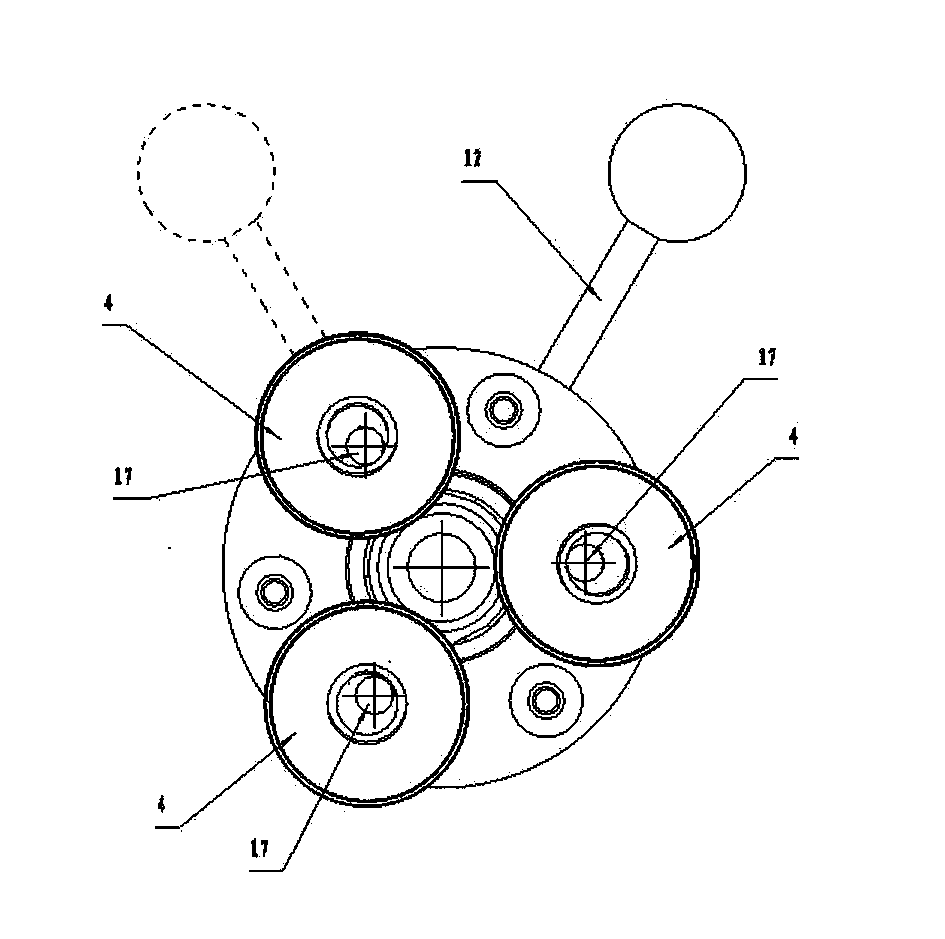

[0021] Embodiment 1: as Figure 1~6 As shown, the axial external thread rolling tool described in this embodiment has a base body, which is characterized in that the base body includes a first assembly, a second assembly, a lock nut 1, a rear cover plate 2, and a thread rolling wheel washer 3. Thread rolling wheel 4, needle roller 5, external fixed cover plate 6 and hexagon socket head screw 7, the first assembly has external spline shaft 8, thread size adjustment cover 9, external spline shaft retaining spring 10, pagoda-shaped Spring 11 and reset handle 12, one end of the external spline shaft passes through the thread size adjustment cover and is fixedly connected with the external spline shaft circlip, and the pagoda-shaped spring is buckled into the thread size adjustment cover in the shape of a compressed knob to fix, The reset handle is fixedly installed on the outside of the thread size adjustment cover; the second assembly has a transmission bull gear 13, a roller mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com