Auxiliary constant-temperature battery box

A battery box and constant temperature technology, which is applied in the field of battery boxes, can solve the problems of slow cooling speed, high heat transfer coefficient, and poor heat transfer performance of batteries, and achieve the effects of reducing temperature difference, increasing heat exchange area, and preventing heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

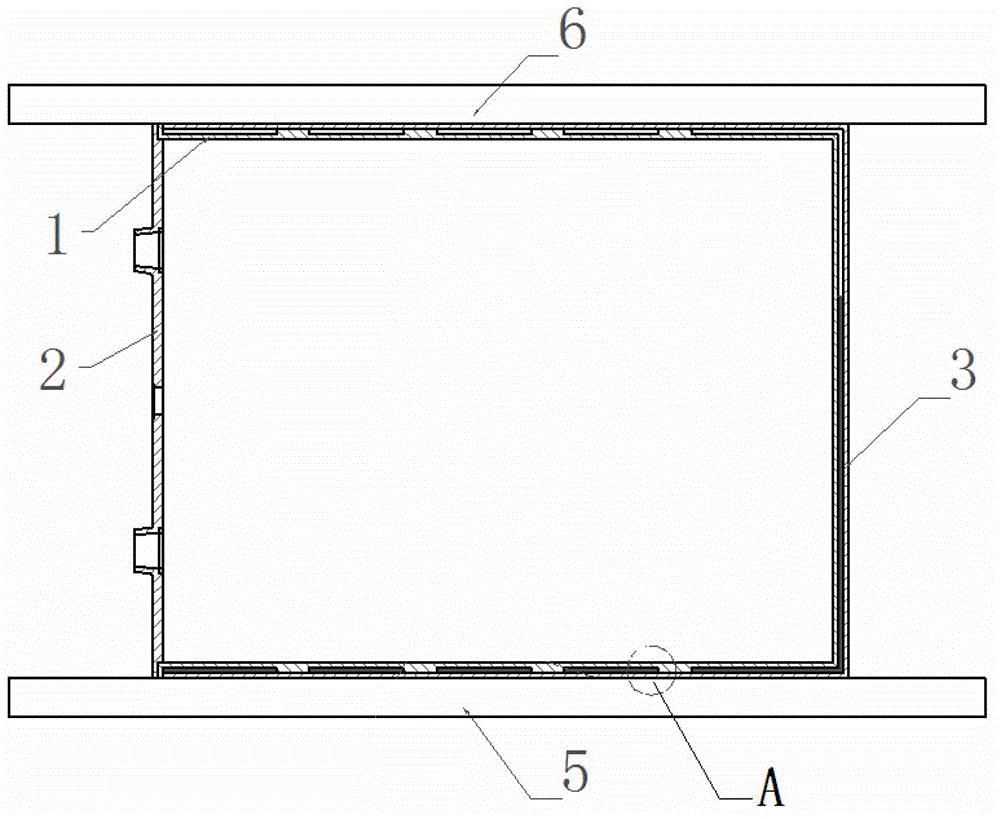

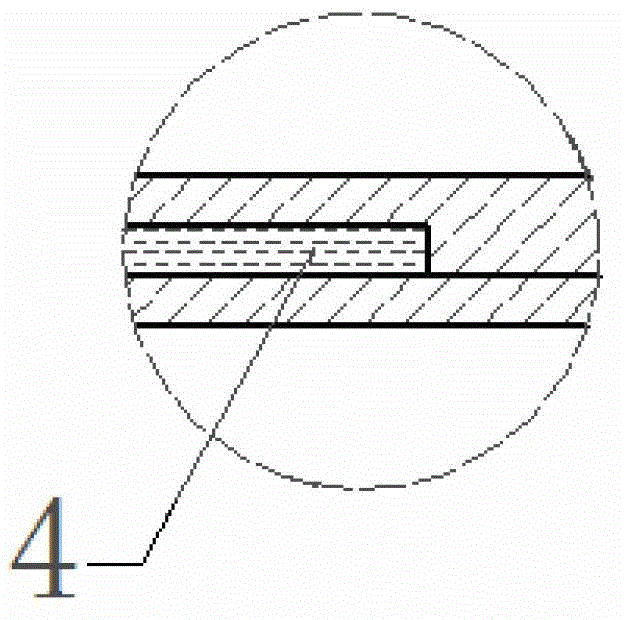

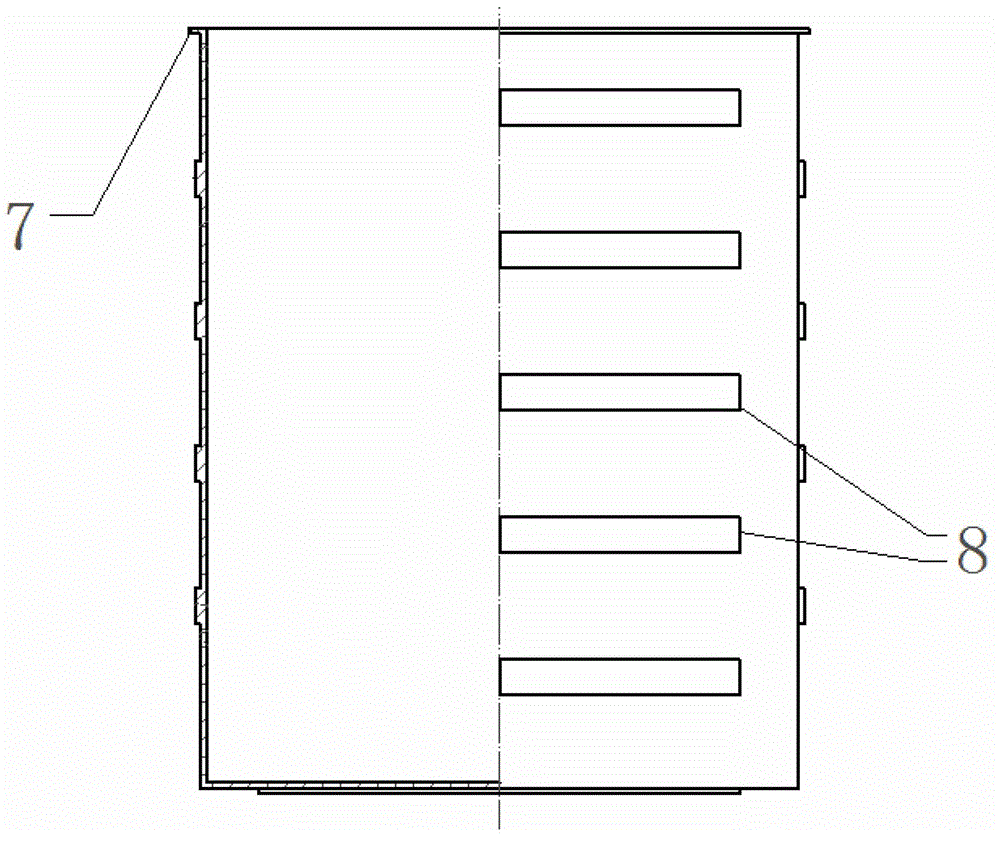

[0027] like Figure 1-8 As shown, an auxiliary constant temperature battery box, the battery box includes an outer shell 3, an inner shell 1, a pole cover 2, a low boiling point medium 4, a heating plate 5 and a cooling plate 6, and a three-sided conductor is formed between the outer shell 3 and the inner shell 1. A closed sealed cavity, the pole cover 2 is set outside the inner shell 1, the low boiling point medium 4 is set in the sealed cavity, and the heating plate 5 and the cooling plate 6 are respectively set at the bottom and top of the shell 3. The inner shell 1 is provided with an inner shell welding platform 7 and a rib boss 8 for welding.

[0028] The steps of assembling the above-mentioned auxiliary constant temperature battery box are as follows: first, place the outer shell 3 in a negative pressure environment, fill it with an appropriate amount of low-boiling point medium 4, then place the inner shell 1 of the battery in the outer shell 3, and place the inner she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com