Double-compaction steel wire rope for harbour machinery and manufacturing method of double-compaction steel wire rope

A steel wire rope and machinery technology, which is applied in the field of double-compacted steel wire rope for port machinery and its production, can solve the problems of increasing the operating cost of port equipment, wasting materials, and mismatching pulleys, etc. , the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

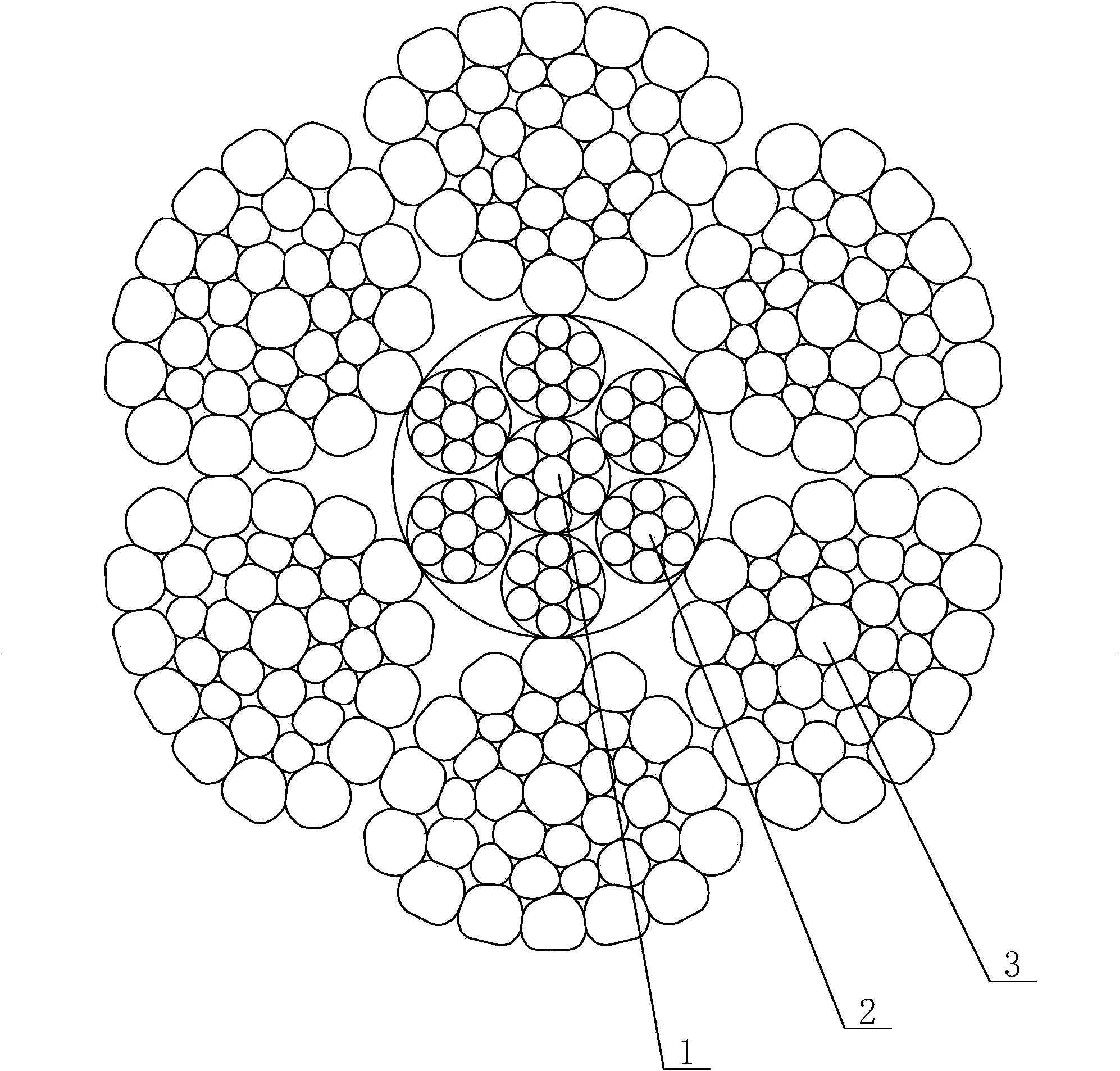

[0018] see figure 1 as shown, figure 1 It is a schematic cross-sectional structure diagram of a double-compacted steel wire rope for port machinery provided in Embodiment 1 of the present invention.

[0019] In this embodiment, a double-compacted steel wire rope for port machinery includes a steel core central strand 1, six steel core outer strands 2 and six outer strands 3, and the steel core outer strands 2 are symmetrically wrapped with twisted steel The core central strand 1 constitutes the steel core, and the outer layer strands 3 are symmetrically twisted around the steel core. The steel wire rope is a compacted rope, and the strands are in surface contact with each other. The outer strands 3 are compacted strands, and the steel wires in the strands are in surface contact.

[0020] Both th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com