Back-to-back air compressor

A technology of compressor and back air, applied in the field of compressors, can solve the problems of increased machining and assembly errors, increased axial dimensions of the compressor, and high difficulty in machining and assembly, and achieves less gas leakage, improved flow field, and balanced shafts. The effect of the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

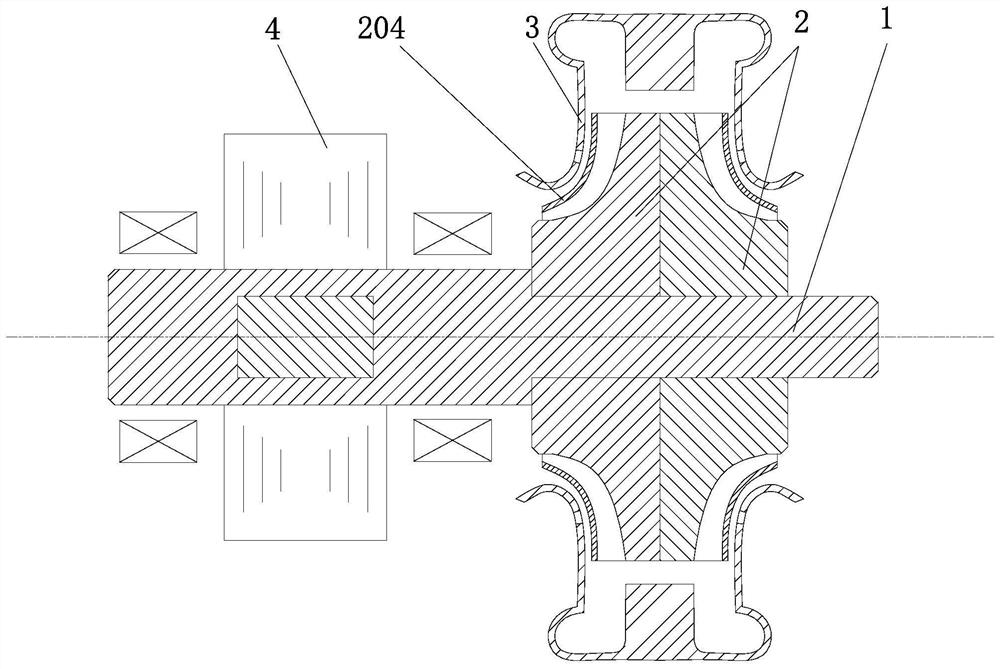

[0043] A back-to-back compressor, comprising a rotating shaft 1, on which an impeller group and a motor 4 are sheathed, and a stator 3 is arranged on the outer cover of the impeller group, as figure 1As shown, wherein, the impeller set includes a pair of impellers 2, and the back air surfaces of the pair of impellers 2 face, contact, and are fixed as one with each other or integrally formed by casting.

[0044] The stator 3 has a symmetrical structure, including a pair of symmetrical casings that are arranged outside a pair of back-to-back impellers 2 . An air passage is formed between the casing and the side impeller 2 .

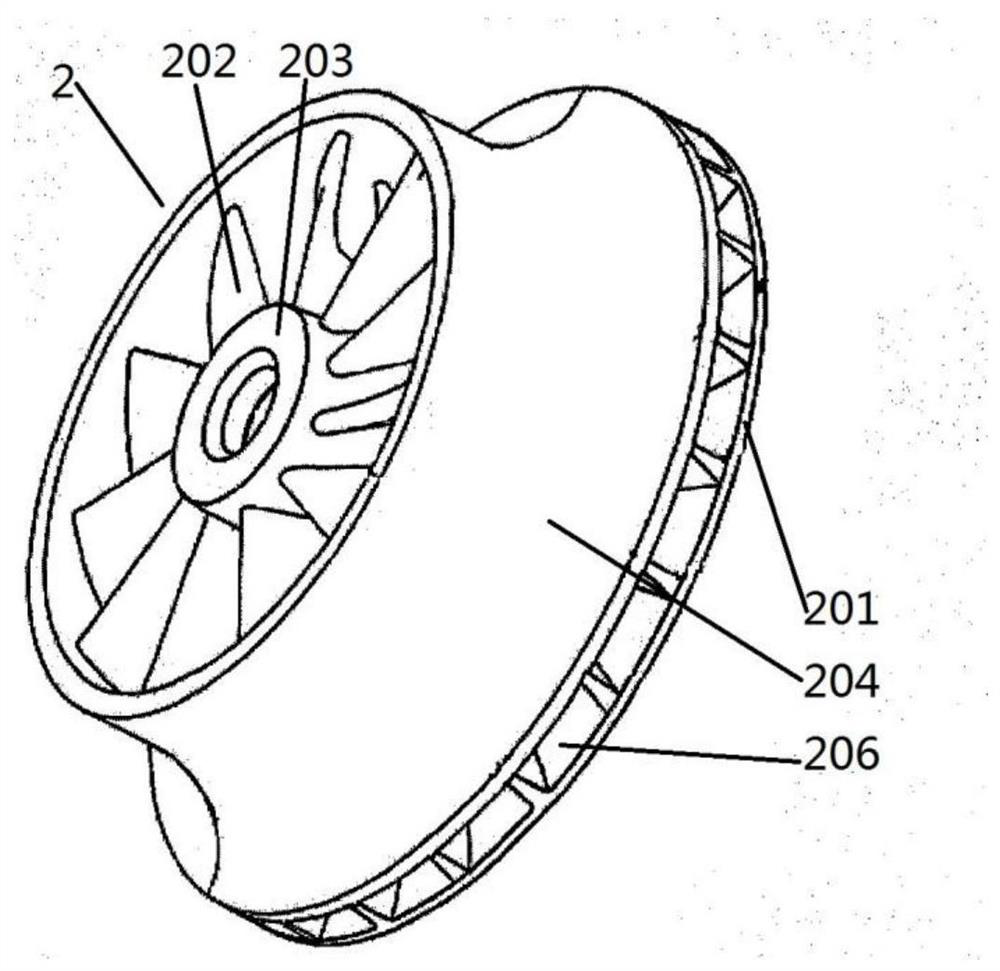

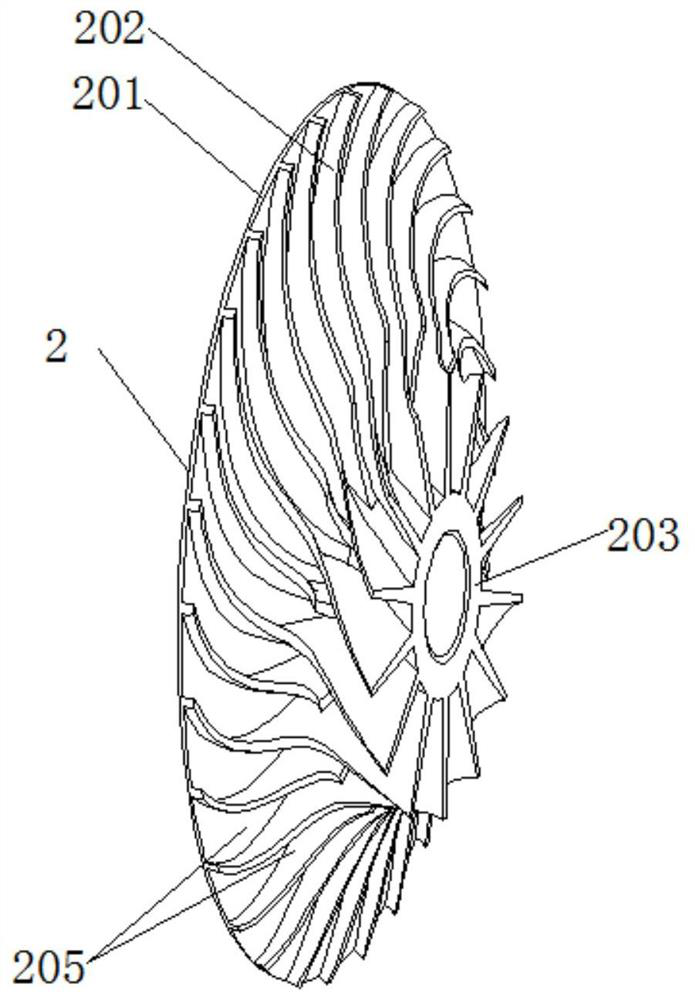

[0045] The impeller is a closed impeller, and its specific structure is: including a rear cover 201, a blade 202, a casing 203 and a front cover 204, such as Figure 2-6 As shown, wherein, the rear cover 201 is arranged at the tail end of the sleeve body 203, and the center of the rear cover 201 and the sleeve body 203 is provided with an integrated throug...

Embodiment 2

[0059] A back-to-back compressor, comprising a rotating shaft 1, on which an impeller group and a motor 4 are sheathed, and a stator 3 is arranged on the outer cover of the impeller group, as Figure 8 As shown, wherein, the impeller set includes a pair of impellers 2, and the back air surfaces of the pair of impellers 2 face, contact, and are fixed as one with each other or integrally formed by casting.

[0060] The stator 3 has a symmetrical structure, including a pair of symmetrical casings that are arranged outside the pair of impellers 2 , and an air passage is formed between the casing and the side impellers 2 .

[0061] The impeller is a closed impeller, and its specific structure is: including a rear cover 201, a blade 202, a casing 203 and a front cover 204, such as Figure 2-6 As shown, wherein, the rear cover 201 is arranged at the tail end of the sleeve body 203, and the center of the rear cover 201 and the sleeve body 203 is provided with an integrated through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com