Flexible high flame retardant biologic aerogel material and preparation method thereof

A bio-based, aerogel technology, applied in coatings and other directions, can solve problems such as poor fire safety, and achieve the effects of improving flame retardant performance, improving mechanical properties, and excellent resilience performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a flexible and highly flame-retardant bio-based airgel material, comprising the following steps:

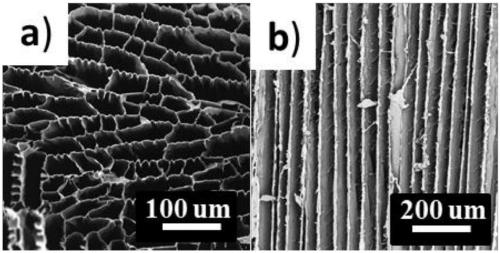

[0042] Step 1, prepare 1% chitosan acetic acid solution of mass percentage concentration, then pour the chitosan acetic acid solution into the middle pass mold with a metal plate at the bottom and place it at -50°C in one direction to be refrigerated and frozen into a solid. Then vacuum freeze-dry in a freeze dryer to make chitosan airgel;

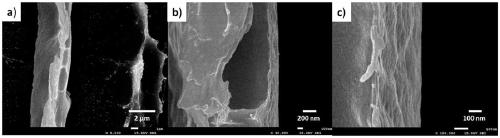

[0043] Step 2, placing the chitosan aerogel in a vacuum oven at 150° C. for heat treatment for 12 hours to obtain a flexible and highly flame-retardant chitosan aerogel.

Embodiment 2

[0045] A method for preparing a flexible and highly flame-retardant bio-based airgel material, comprising the following steps:

[0046] Step 1, prepare 3% chitosan acetic acid solution of mass percentage concentration, then pour the chitosan acetic acid solution into the middle pass mold with a metal plate at the bottom and place it at -80°C in one direction to be refrigerated and frozen into a solid. Then vacuum freeze-dry in a freeze dryer to make chitosan airgel;

[0047] Step 2, placing chitosan airgel in a vacuum oven at 180°C for heat treatment for 15 hours to obtain flexible and highly flame-retardant chitosan airgel;

Embodiment 3

[0049] A method for preparing a flexible and highly flame-retardant bio-based airgel material, comprising the following steps:

[0050] Step 1, preparing 5% chitosan acetic acid solution in mass percent concentration, then pouring the chitosan acetic acid solution into a central pass mold with a metal plate at the bottom and placing it at -150°C in one direction to be refrigerated and frozen into a solid. Then vacuum freeze-dry in a freeze dryer to make chitosan airgel;

[0051] Step 2, placing chitosan airgel in a dry vacuum environment at 200°C for heat treatment for 6 hours to obtain flexible and highly flame-retardant chitosan airgel; the dry vacuum environment is to place a sufficient amount of Phosphorus pentoxide to ensure the smooth progress of the curing process;

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com