Plasma etching method and computer-readable storage medium

A plasma and etching technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as isotropy, achieve the effect of ensuring etching selectivity and preventing undercutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

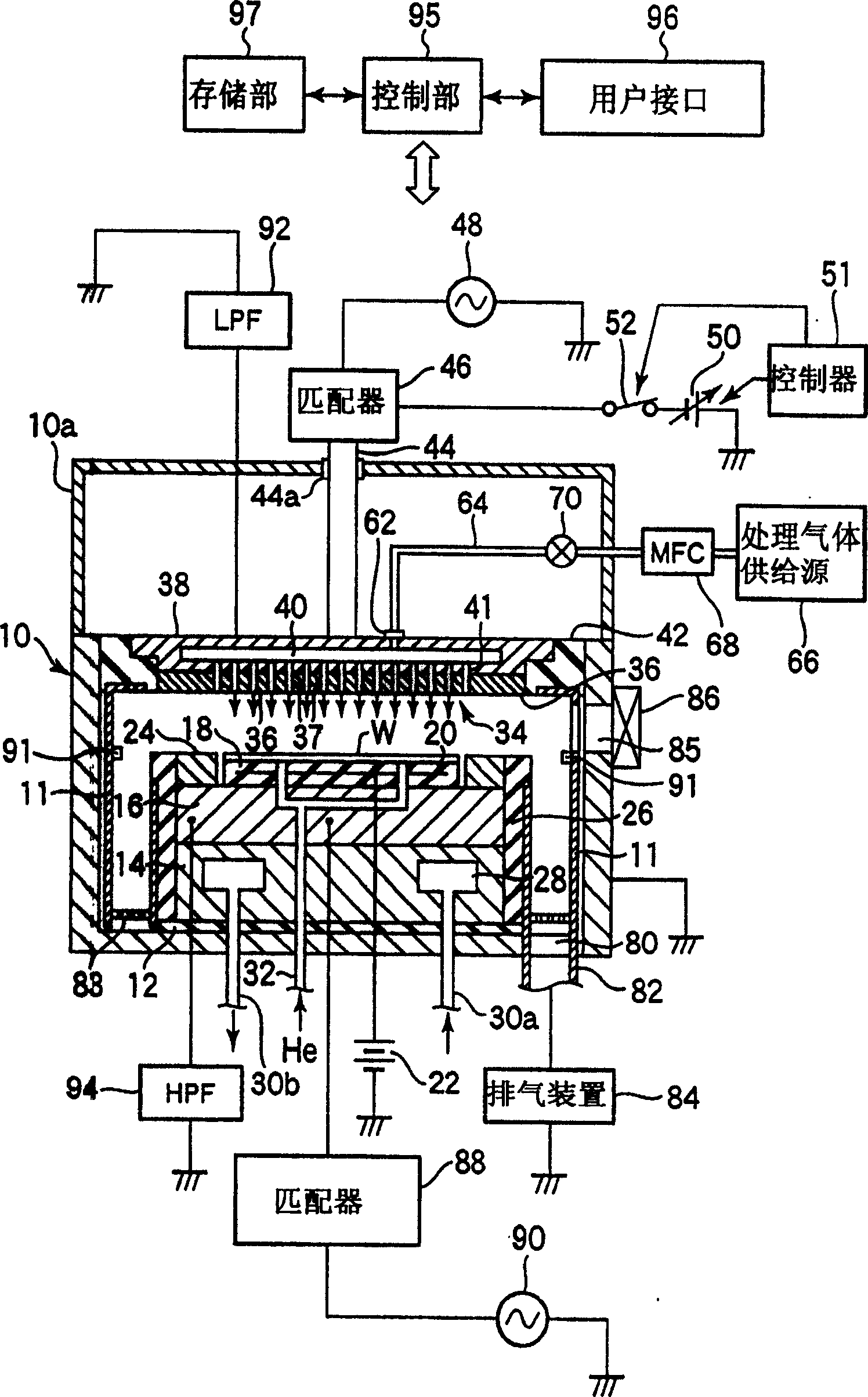

[0050] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0051] figure 1 It is a schematic cross-sectional view showing an example of a plasma etching apparatus used in the practice of the present invention.

[0052] This plasma etching apparatus is configured as a capacitively coupled parallel plate plasma etching apparatus, and has a substantially cylindrical chamber (processing container) 10 made of, for example, aluminum whose surface has been anodized. The chamber (processing container) 10 is securely grounded.

[0053]At the bottom of the cavity 10 , a cylindrical base support 14 is disposed via an insulating plate 12 made of ceramics or the like, and a base 16 made of, for example, aluminum is provided on the base support 14 . The susceptor 16 constitutes a lower electrode, and a semiconductor wafer W serving as a substrate to be processed is placed thereon.

[0054] On the upper surface of susceptor 16, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com