Photoelectric composite cable with special-shaped filling material

A technology of photoelectric composite cable and special-shaped filling rope, which is applied in the field of cables, and can solve problems such as increased cost, difficult recovery, troublesome removal of loose tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Implementation example 1, implementation example 2, and implementation example 3 are embodiments of special-shaped filling ropes in the present invention; implementation example 4 and implementation example 5 are embodiments of photoelectric composite cables with special-shaped filling in the present invention.

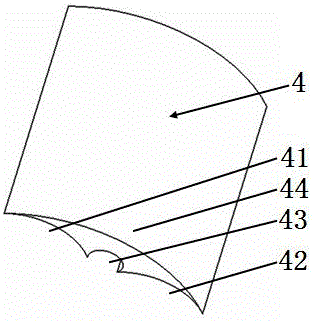

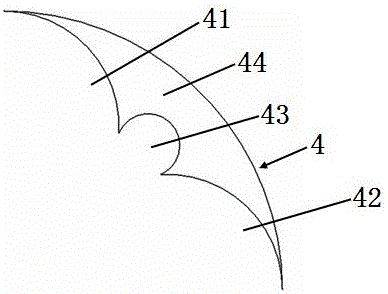

[0041] Implementation example 1

[0042] please see figure 1 figure 2 , optical cable or cable or photoelectric composite cable or photoelectric composite cable with a special-shaped filling rope, which includes a rope body 4, which is characterized in that the rope body is composed of four sections of cylindrical arcs, and the other end of the first cylindrical arc 41 is connected to the third cylinder One end of arc body 43, the other end of the third cylindrical arc body 43 connects one end of second cylindrical arc body 42, one end of fourth cylindrical arc body 44 connects one end of first cylindrical arc body 41, the fourth cylindrical arc body 44 Th...

Embodiment 2

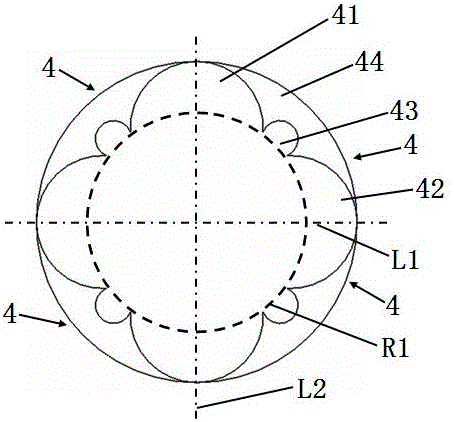

[0046] please see image 3 , and refer to figure 1 with figure 2 The special-shaped filling rope for optical cable or electric cable or photoelectric composite cable or photoelectric composite cable is characterized in that it is formed by splicing successively four small-structure filling rope bodies, and the four small-structure filling rope bodies are assembled into a complete cylinder body surface; the small structure filled rope body includes a rope body 4, and the rope body is composed of four sections of cylindrical arcs, the other end of the first cylindrical arc 41 is connected to one end of the third cylindrical arc 43, and the third cylindrical arc The other end of 43 connects one end of the second cylindrical arc body 42, one end of the fourth cylindrical arc body 44 connects one end of the first cylindrical arc body 41, and the other end of the fourth cylindrical arc body 44 connects the other end of the second cylindrical arc body 42 One end; the bending of th...

Embodiment 3

[0049] please see Figure 4 , and refer to Figure 1 to Figure 3 ; optical cable or electric cable or photoelectric composite cable or photoelectric composite cable with special-shaped filling rope, basically the same as implementation example 2, the difference is that it is formed by one extrusion molding of four small structure filling rope bodies, and the four small structure filling The rope body forms a complete cylinder surface; the small structure filled rope body includes a rope body 4, and the rope body is composed of four sections of cylindrical arcs, and the other end of the first cylindrical arc 41 is connected to the third cylindrical arc 43. One end, the other end of the third cylindrical arc body 43 is connected to one end of the second cylindrical arc body 42, one end of the fourth cylindrical arc body 44 is connected to one end of the first cylindrical arc body 41, and the other end of the fourth cylindrical arc body 44 is connected to the second cylindrical a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com