Preparation method of MXene-based composite aerogel

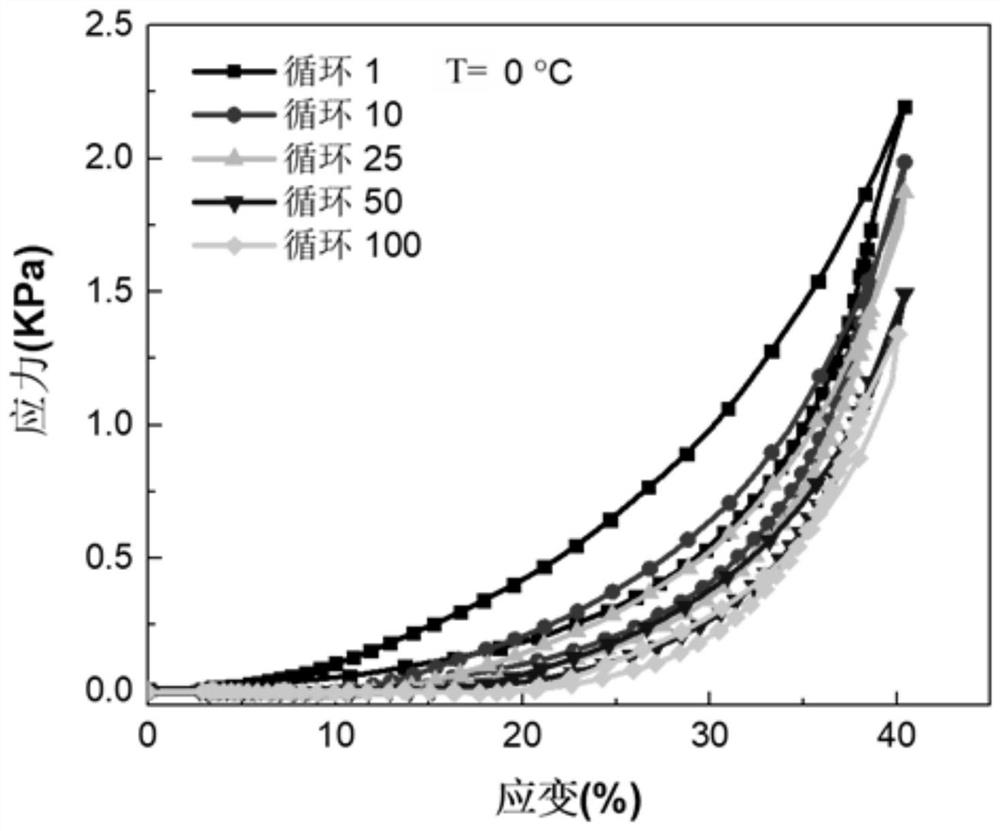

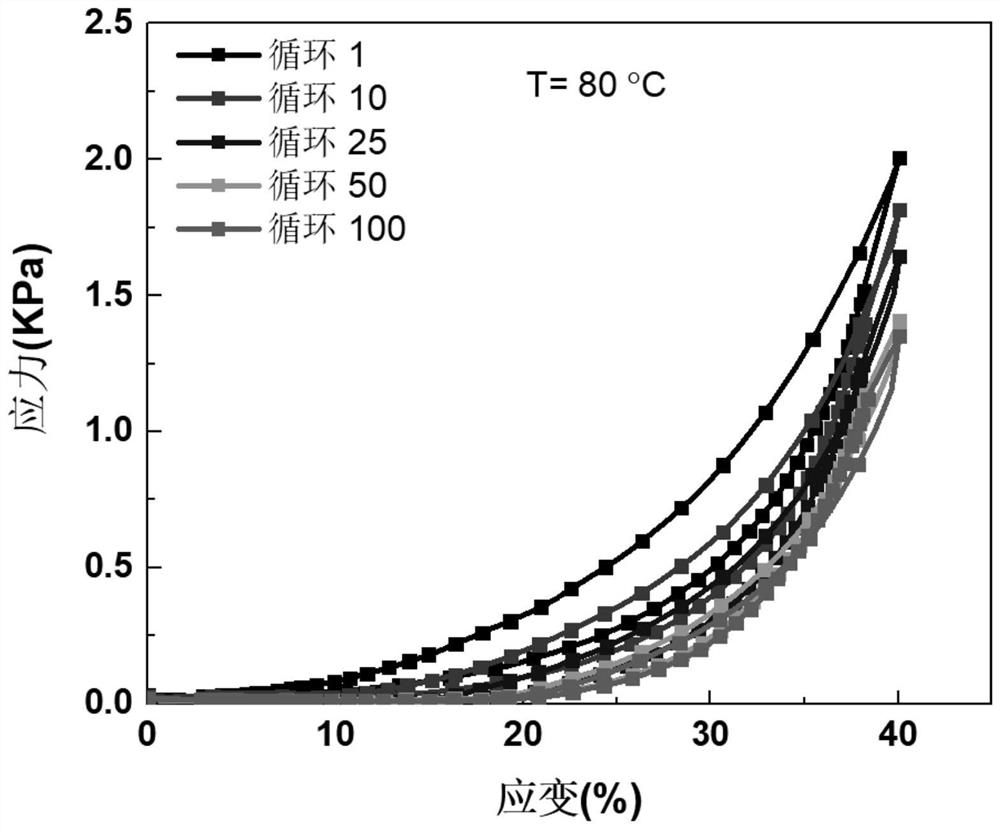

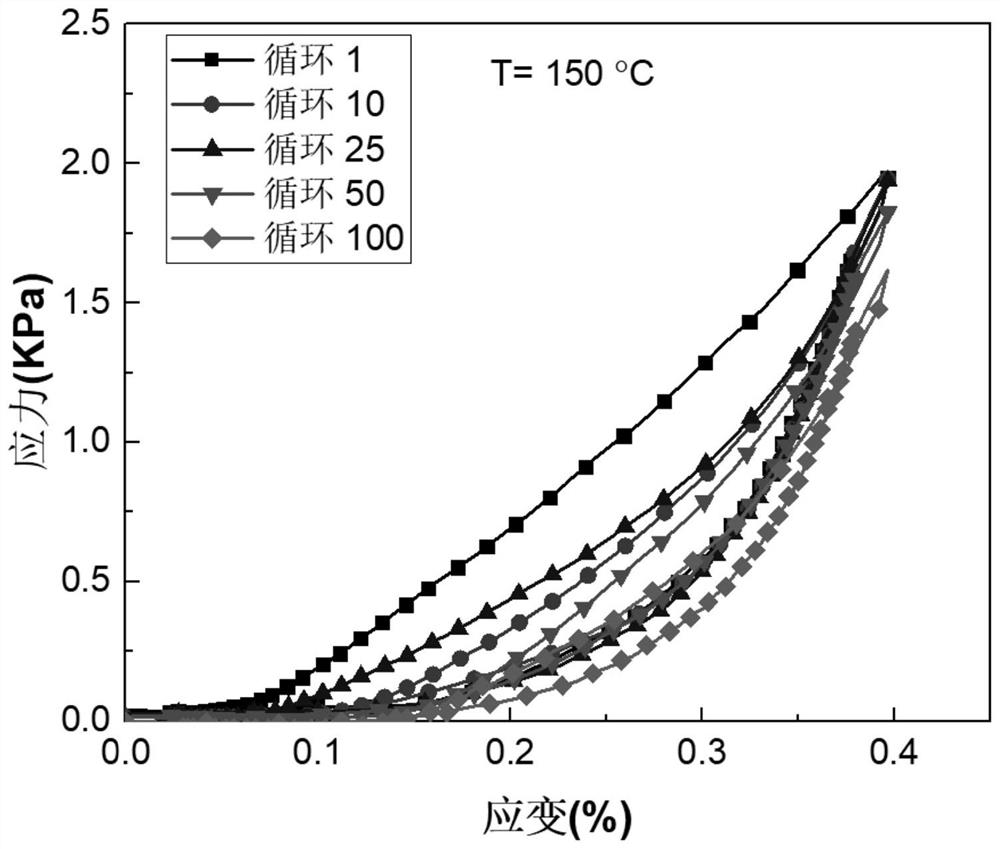

A composite aerogel, nanocellulose technology, applied in aerogel preparation, chemical instruments and methods, colloid chemistry and other directions, can solve the problems of poor electrochemical performance, poor mechanical stability, etc., achieve good compression recovery ability, Electrochemical performance improvement, the effect of suppressing stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of MXene-based composite airgel, comprising:

[0032] Put 1g of lithium fluoride into 20mL of hydrochloric acid (the concentration of hydrochloric acid is 9mol / L) and stir for 30min, then add 1g of precursor MAX to continue stirring and react. The reaction temperature is 35°C and the time is 24h. After the reaction , after ultrasonication and centrifugation, the centrifugation speed is 6000rpm, the upper layer suspension is taken, and MXene is obtained after freeze-drying;

[0033] Put 3g of nano-cellulose crystals into 50mL of deionized water, stir for 6h, and sonicate for 10min to obtain a dispersion of nano-cellulose crystals;

[0034] Add 1mL of perfluorosilane coupling agent into the nano-cellulose crystal dispersion, add dropwise acetic acid to adjust the pH to 5, and then place it in a hydrothermal kettle for hydrothermal reaction. The temperature of the hydrothermal reaction is 80°C and the time is After 12 hours of reaction, centrifuge at ...

Embodiment 2

[0038]Prepare MXene-based composite airgel according to the method of Example 1, the difference is that 1g of precursor MAX is added to continue stirring and the reaction time is 36h; the time of chemical crosslinking reaction is 13h; the rate of liquid nitrogen freezing is 10 °C / min.

Embodiment 3

[0040] Prepare MXene-based composite airgel according to the method of Example 1, the difference is that 1 g of precursor MAX is added to continue stirring and the reaction time is 48 h; the time of chemical cross-linking reaction is 16 h; the rate of liquid nitrogen freezing is 15 h °C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com