Method and device for performing degreasing treatment on steel wire

A technology of degreasing treatment and steel wire, which is applied in the electrolysis process and electrolysis components, etc., can solve the problems of difficult removal of saponified grease and poor degreasing effect of bead steel wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

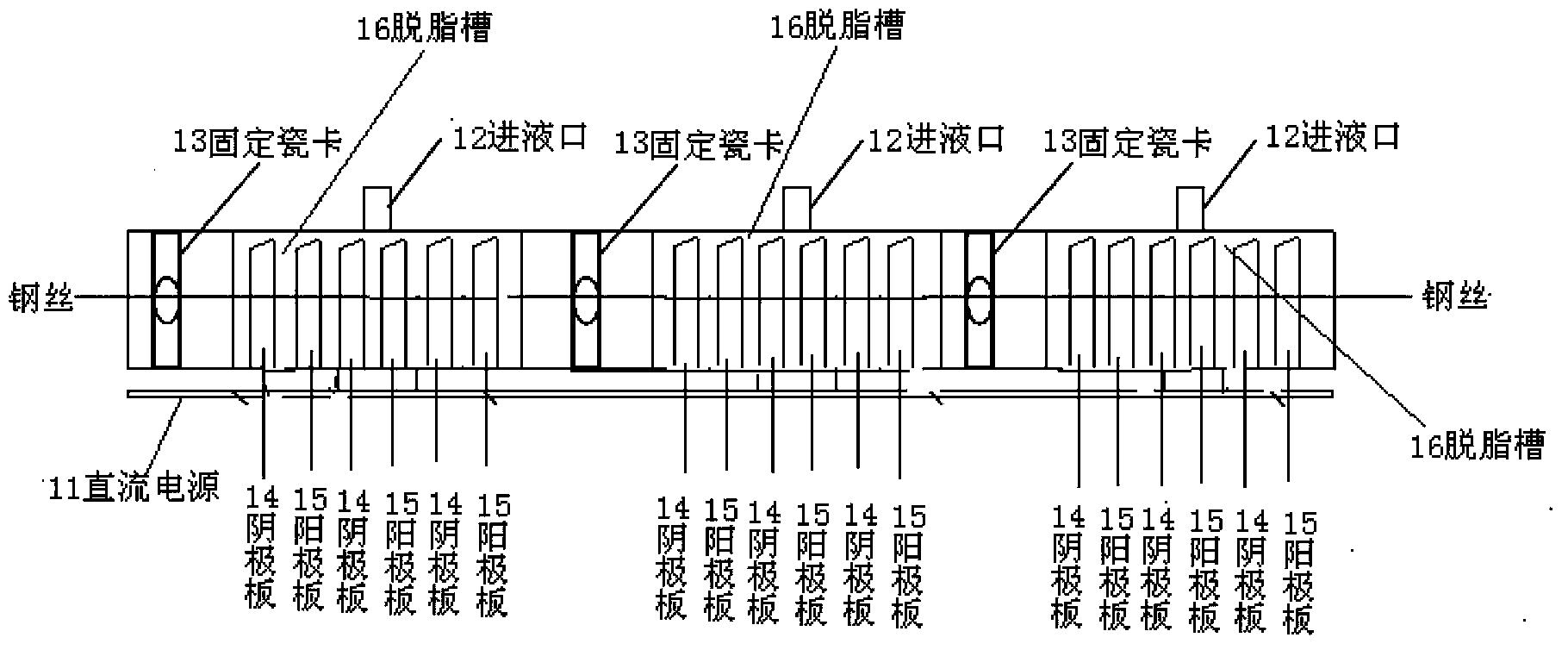

[0020] The structural diagram of a device for degreasing steel wire provided in this embodiment is as follows: figure 1 shown, including:

[0021] The degreasing tank 16 is used to contain the electrolyte, and the electrolyte has a displacement effect on the saponified fat and other grease on the surface of the steel wire passing through the electrolyte, so that the adhesion of the grease to the steel wire is reduced. The top of the degreasing tank is provided with a liquid inlet 12 through which electrolyte is poured into the degreasing tank. The main component of the above-mentioned electrolyte is sodium hydroxide, and its aqueous solution has strong conductivity. In order to prevent corrosion of the steel wire matrix, a small amount of nitrite oxidizer is also added. Therefore, the composition of the above-mentioned electrolytic solution is a large part of sodium hydroxide and a small part of nitrite oxidizing agent.

[0022] DC power supply 11, used to provide DC power ...

Embodiment 2

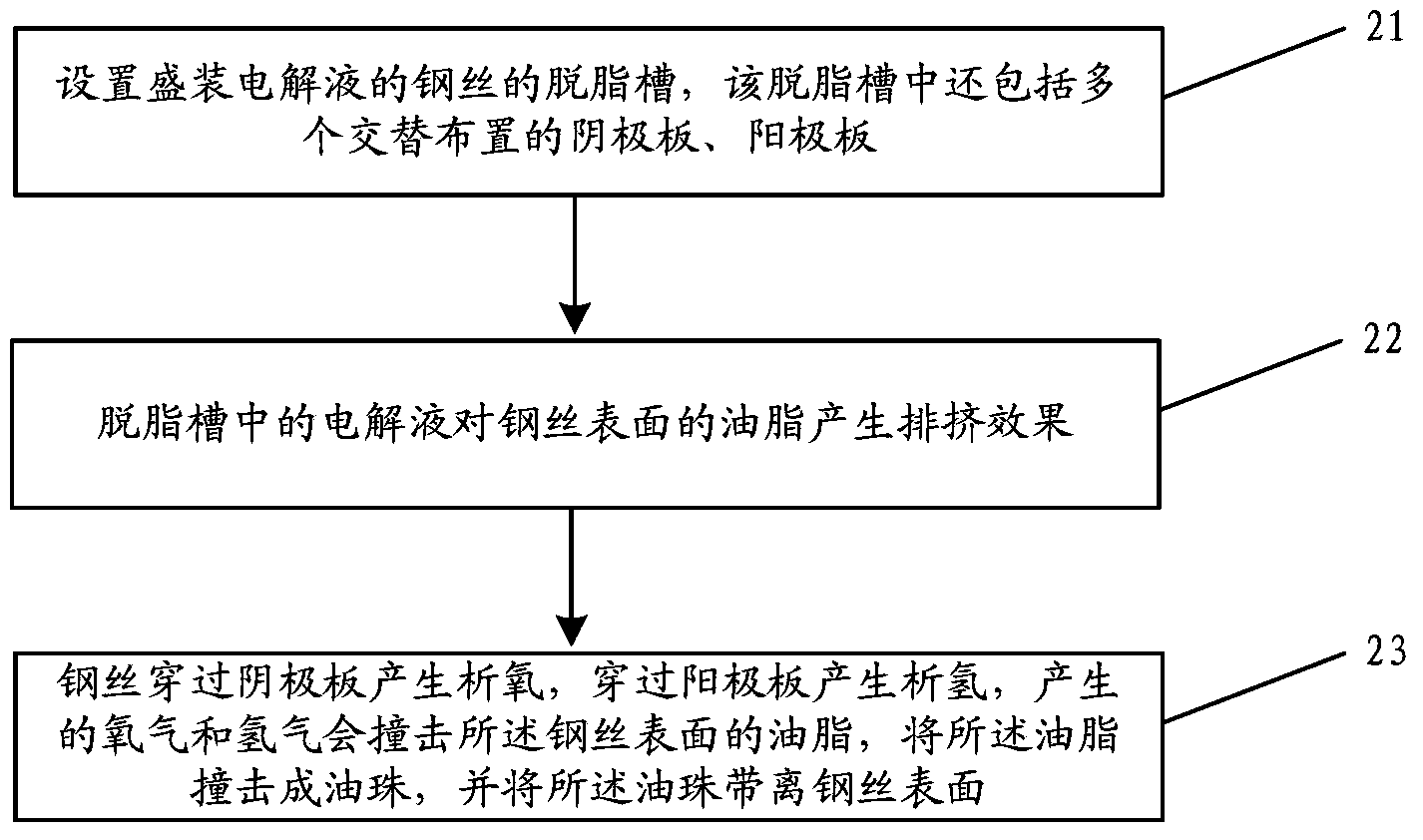

[0037] The processing flow of a method for degreasing steel wire provided by this embodiment is as follows: figure 2 As shown, the following processing steps are included:

[0038] Step 21, setting up a degreasing tank for the steel wire containing the electrolyte, and the degreasing tank also includes a plurality of alternately arranged cathode plates and anode plates.

[0039] A degreasing tank for steel wires such as bead steel wires is provided, and the degreasing tank is used to contain electrolyte. Each degreasing tank includes multiple pairs of cathode plates and anode plates, a liquid inlet, and a DC power supply. Wherein, the liquid inlet is arranged on the upper part of the degreasing tank, through which the electrolyte is poured into the degreasing tank. The DC power supply is arranged at the lower part of the degreasing tank, and the DC power supply supplies power to the electrolyte, the cathode plate and the anode plate.

[0040] The cathode plate is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com