Method for preparing lithium ion capacitor using carbon nanotube/urea-formaldehyde resin carbon coated spherical microcrystalline graphite material

A technology of microcrystalline graphite and urea-formaldehyde resin, which is applied in the field of lithium-ion batteries, can solve the problems of solid electrolyte interfacial film damage, irreversible loss of active materials, and low initial charge-discharge efficiency, so as to improve the tap density, promote cleaning and removal, and improve storage capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

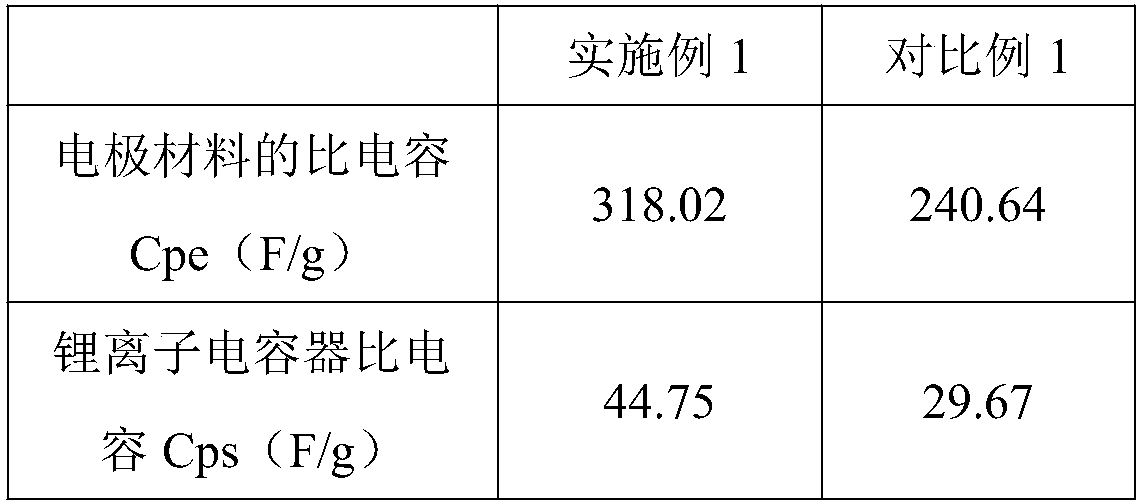

Embodiment 1

[0038]This embodiment is a preparation method of a lithium ion capacitor using carbon nanotubes / urea-formaldehyde resin carbon-coated spherical microcrystalline graphite material, using carbon nanotubes / urea-formaldehyde resin carbon-coated spherical microcrystalline graphite material as the negative electrode, and the prepared iron phosphate The electrode sheet made of lithium / expanded microcrystalline graphite / carbon composite material is used as the positive electrode, and a polypropylene diaphragm is sandwiched between the positive and negative electrodes to assemble a lithium ion capacitor. Lithium nitrate with a concentration of 1mol / L is injected between the positive and negative electrodes The aqueous solution is the electrolyte;

[0039] Wherein, the carbon nanotube / urea-formaldehyde resin carbon-coated spherical microcrystalline graphite material is prepared by the following method:

[0040] S1. Using microcrystalline graphite as raw material, spherical microcrystall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com