Feed crushing and processing device for wild duck breeding

A processing device and feed technology, applied in feed, mixer with rotating stirring device, application, etc., can solve the problems of low efficiency, manpower consumption, bloated mechanism, etc., and achieve the goal of reducing production cost, improving production efficiency, and streamlining the mechanism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

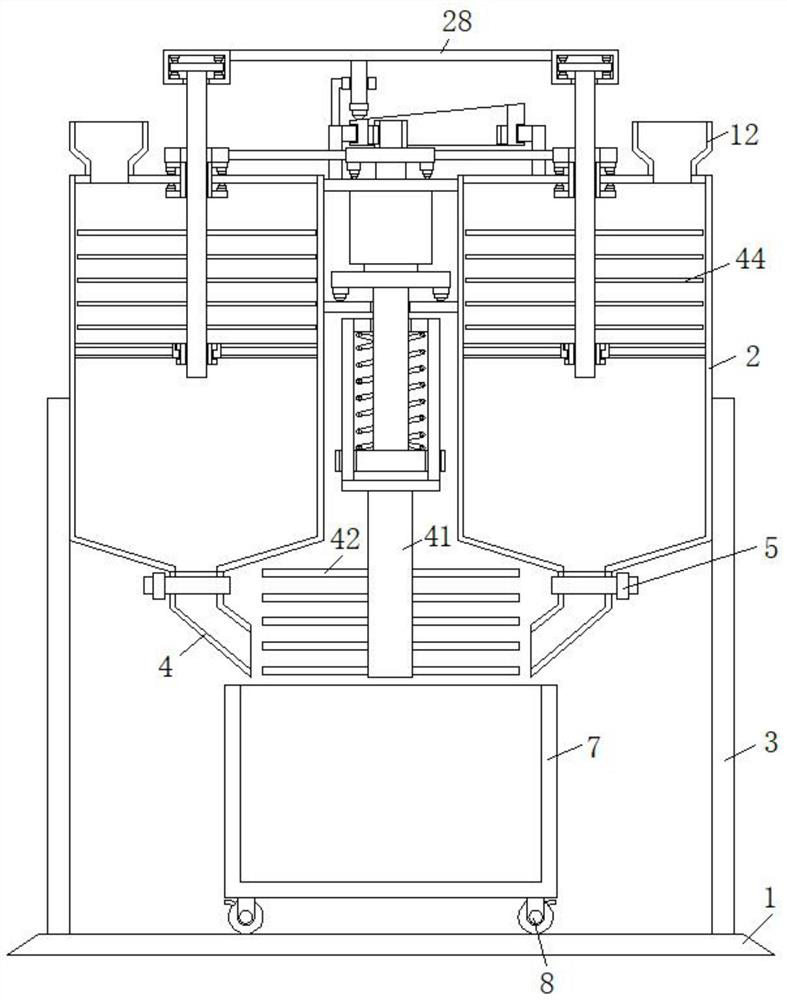

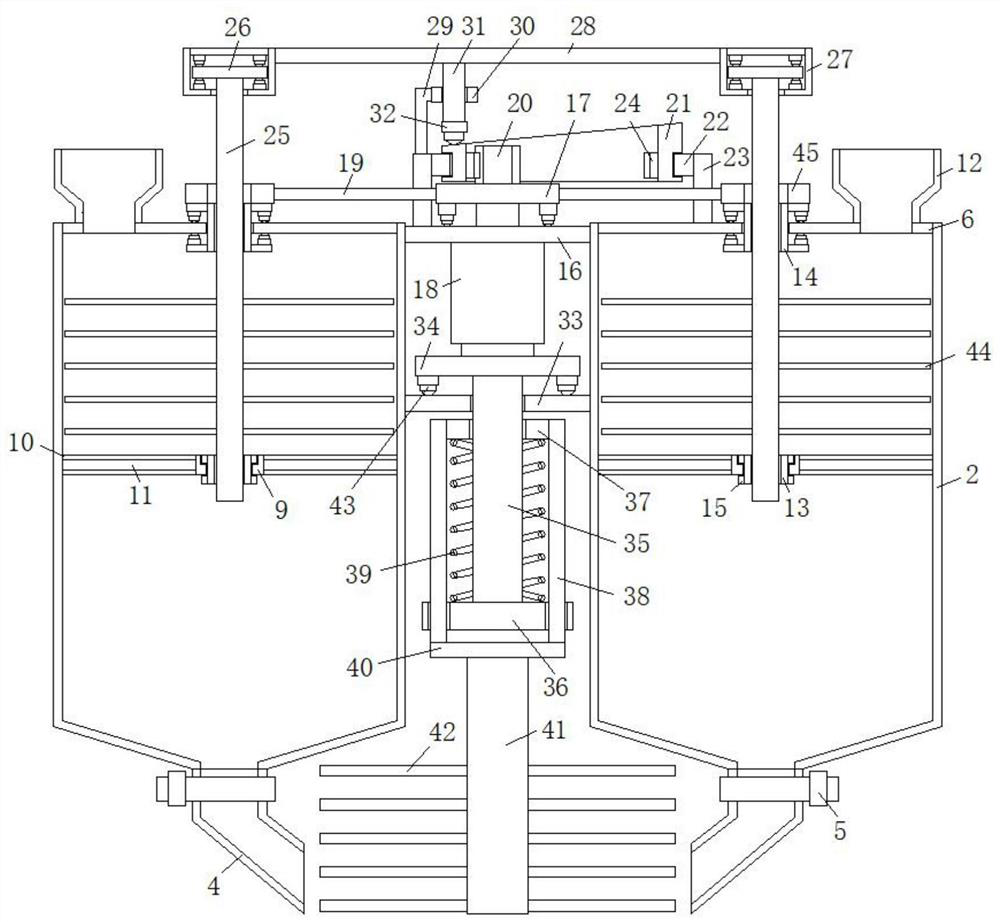

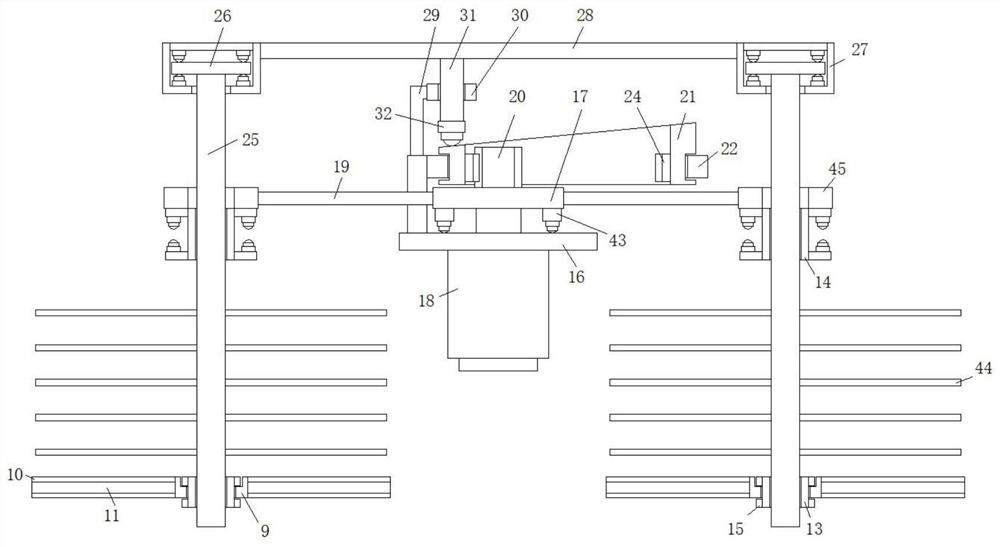

Embodiment 1

[0029] refer to Figure 1-7, a feed crushing and processing device for wild duck breeding, comprising a bottom plate 1, a crushing box 2 is arranged vertically above the bottom plate 1, there are several crushing boxes 2 and they are arranged in a divergent manner, and there is a The support frame 3, the bottom end of the crushing box 2 is a closed structure and is connected with a discharge folding pipe 4, and the pipe body of the discharge folding pipe 4 is provided with a valve 5, and the top side of the bottom plate 1 is provided with a collection box 7, and the crushing box The top inner wall of 2 is fixedly connected with an inner plate 6, and a central shaft ring 9 is arranged in the crushing box 2, and a plurality of struts 10 are fixedly connected to the vertical outer side of the central shaft ring 9 in a divergent manner, and a screen is arranged between each strut 10. The net 11, the plate body of the inner plate 6 is provided with a feed hole and is connected with...

Embodiment 2

[0032] Such as Figure 1-7 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the second mounting plate 33 and the bottom support plate 36 are provided with through holes, and the rail column 35 and the linkage rod 38 respectively pass through the through holes.

[0033] In this embodiment, the vertical movement of the stirring spindle 41 and the stirring paddle 42 is realized by sliding the linkage rod 38 up and down, and they are removed from the collection box 7 .

Embodiment 3

[0035] Such as Figure 1-7 As shown, this embodiment is basically the same as Embodiment 1. Preferably, universal balls 43 are installed at the bottom edge positions of the driving sprocket 17 and the second circular plate 34 .

[0036] In this embodiment, the universal ball 43 reduces the friction when the driving sprocket 17 and the second circular plate 34 rotate, and improves the energy utilization rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com