Superfine crushing device and superfine crushing method for preparing mixed feed

An ultrafine pulverization and mixing technology, which is applied in feed, application, grain processing, etc., can solve the problems of low uniformity of pulverization, difficult absorption of animals, poor pulverization effect, etc., and achieve high pulverization precision and lower temperature , The effect of crushing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

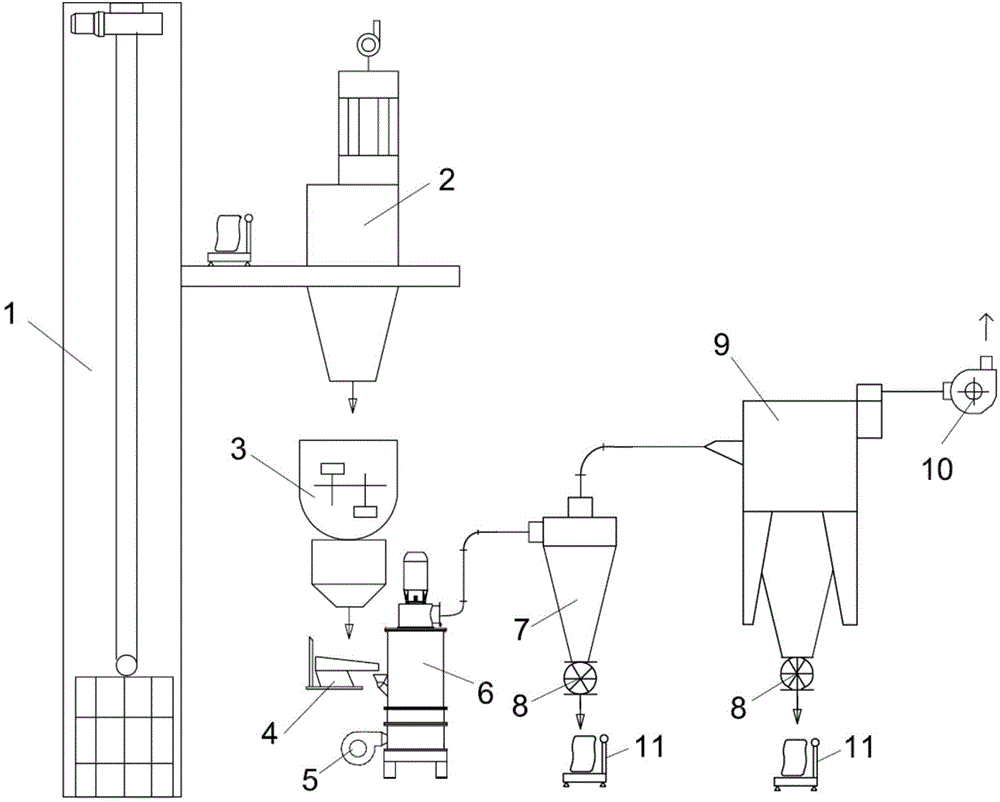

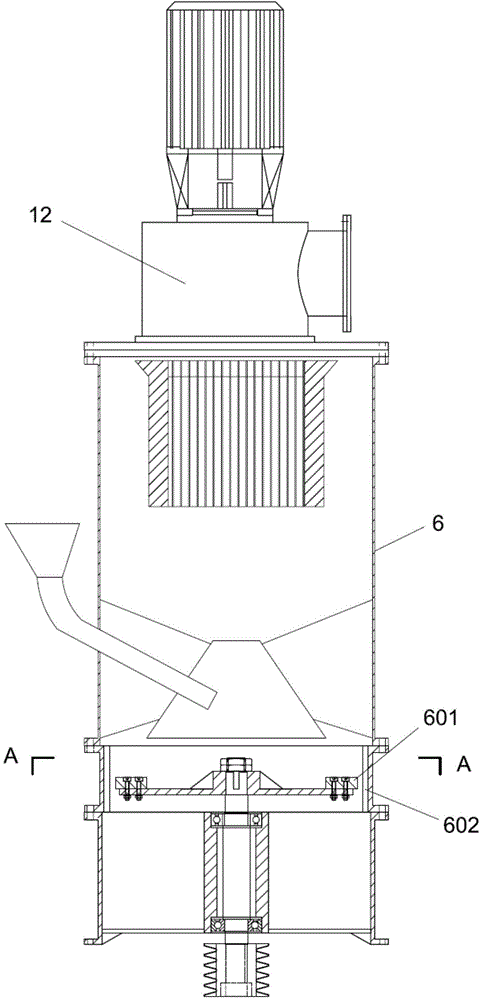

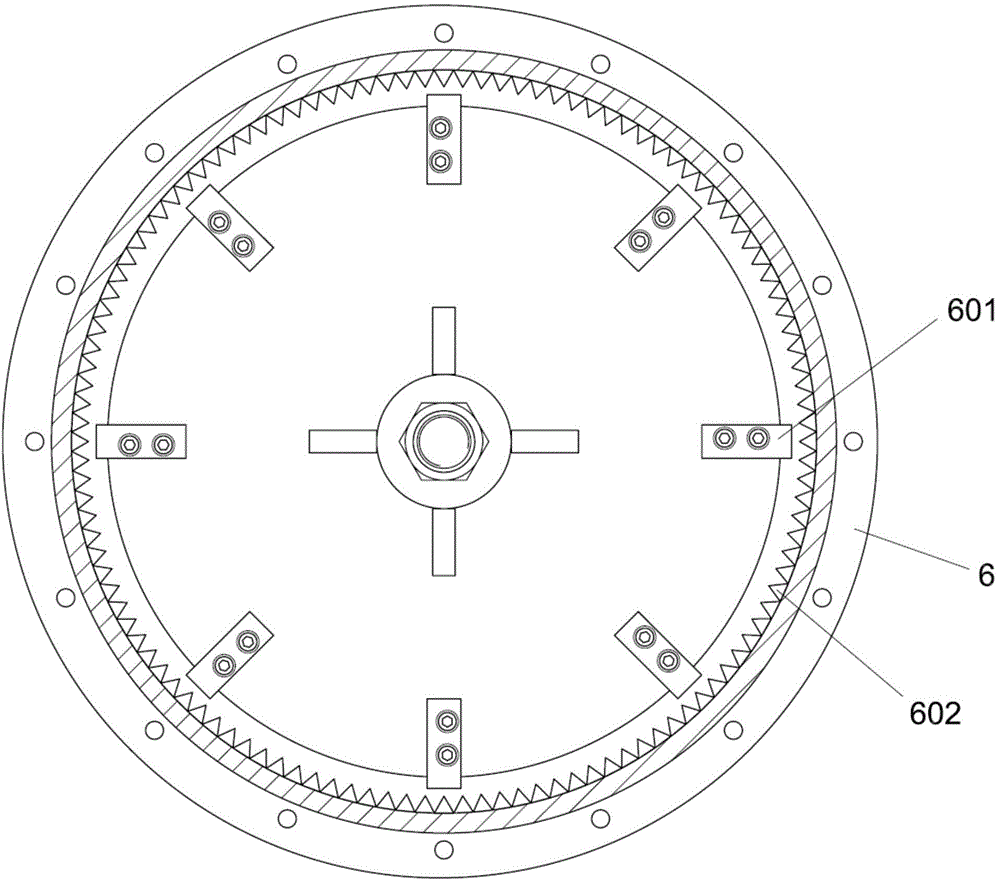

[0018] refer to Figure 1-3 , a kind of superfine pulverizing device for preparing mixed feed of the present invention, comprises elevator 1, first pulse dust collector 2, mixer 3, vibrating feeder 4, pulverizer 6, cyclone separator 7 arranged in sequence , the second pulse dust collector 9 and the induced draft fan 10, the first pulse dust collector 2 described above is fixedly installed on the outer wall of the elevator 1, the discharge port of the first pulse dust collector 2 is located above the feed inlet of the mixer 3, and the mixer 3 The described vibrating feeder 4 is installed between the discharge port of the pulverizer 6 and the feed port of the pulverizer 6, and the discharge port of the pulverizer 6 is equipped with a classifier 12, and through the feed port of the classifier 12 and the cyclone separator 7 connected, the dust outlet of the cyclone separator 7 is connected to the second pulse dust collector 9 and the induced draft fan 10 in turn, and the lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com