High-precision low-temperature crushing device for production of glass substrate frame

A technology of low temperature pulverization and substrate machine, applied in grain processing and other directions, can solve the problems of inability to achieve pulverization accuracy, heat cannot be removed in time, unfavorable low temperature pulverization, etc., and achieve the effect of improving pulverization effect, reducing heat and improving pulverization accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

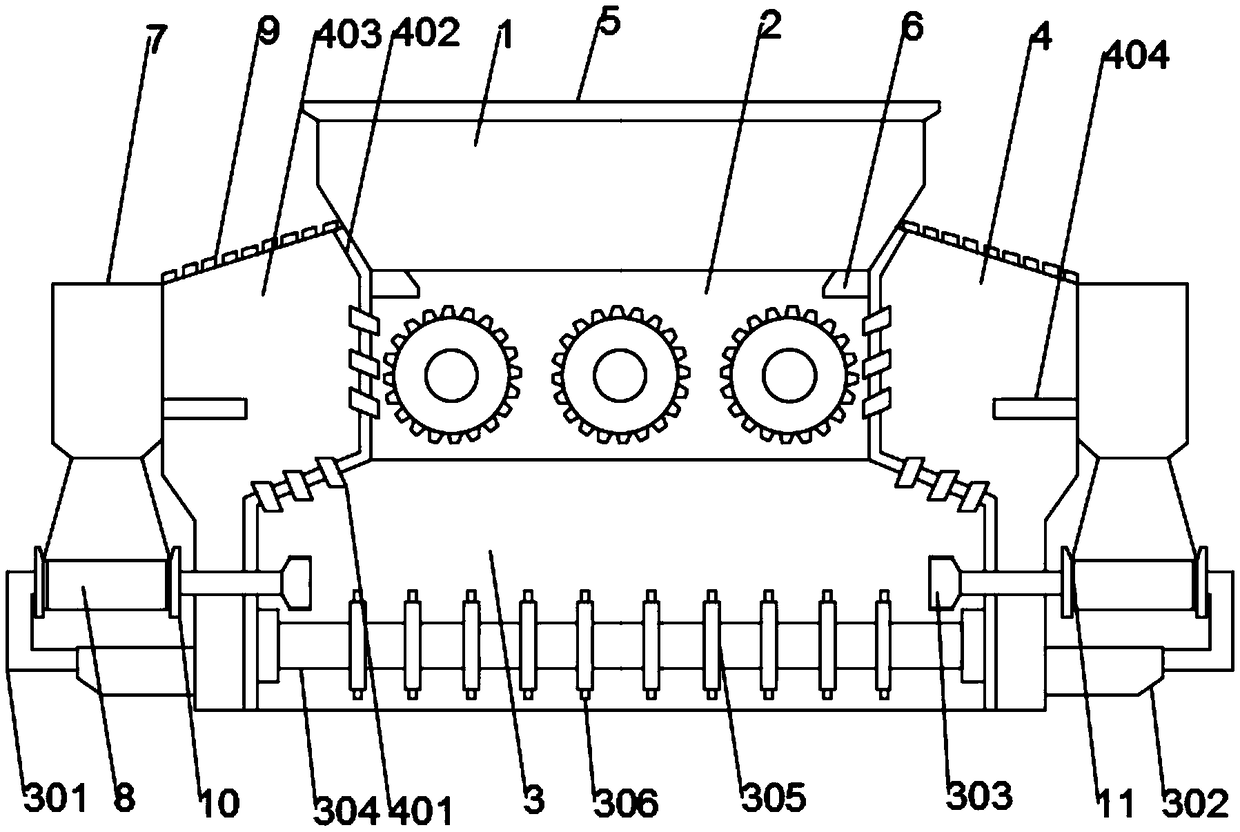

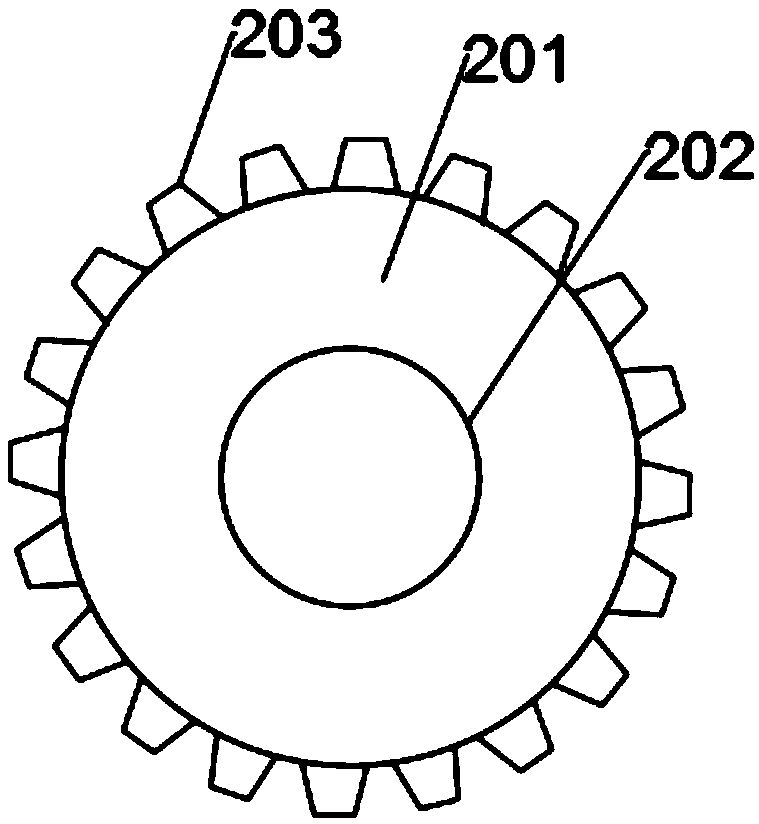

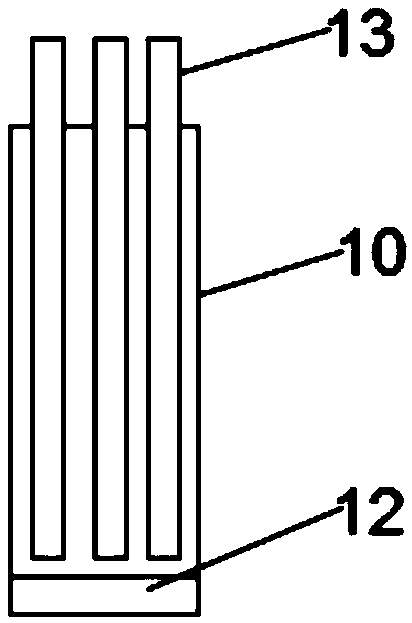

[0027] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides a high-precision low-temperature crushing device for the production of glass substrate frames, including a feed cylinder 1, a coarse material crushing cylinder 2 connected to the bottom of the feed cylinder 1, a coarse material crushing cylinder 2 connected to the The fine material crushing cylinder 3 at the bottom and the cooling cylinder 4 arranged outside the coarse material crushing cylinder 2 and the fine material crushing cylinder 3, the top of the feeding cylinder 1 is hingedly connected with a top cover 5, and the bottom end of the feeding cylinder 1 is connected to There is a conical distributing disc 6, and several parallel crushing rollers 201 are evenly and equally spaced inside the coarse material crushing cylinder 2, and the crushing rollers 201 are all driven by a drive shaft 202, and the surface of the crushing rollers 201 is provided with Several crushing teeth 203 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com