Preparation of chlorinated polythylene

A technology of chlorinated polyethylene and high-density polyethylene, applied in the field of preparation of chlorinated polyethylene, can solve problems such as impact resistance, reduction of elasticity and flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

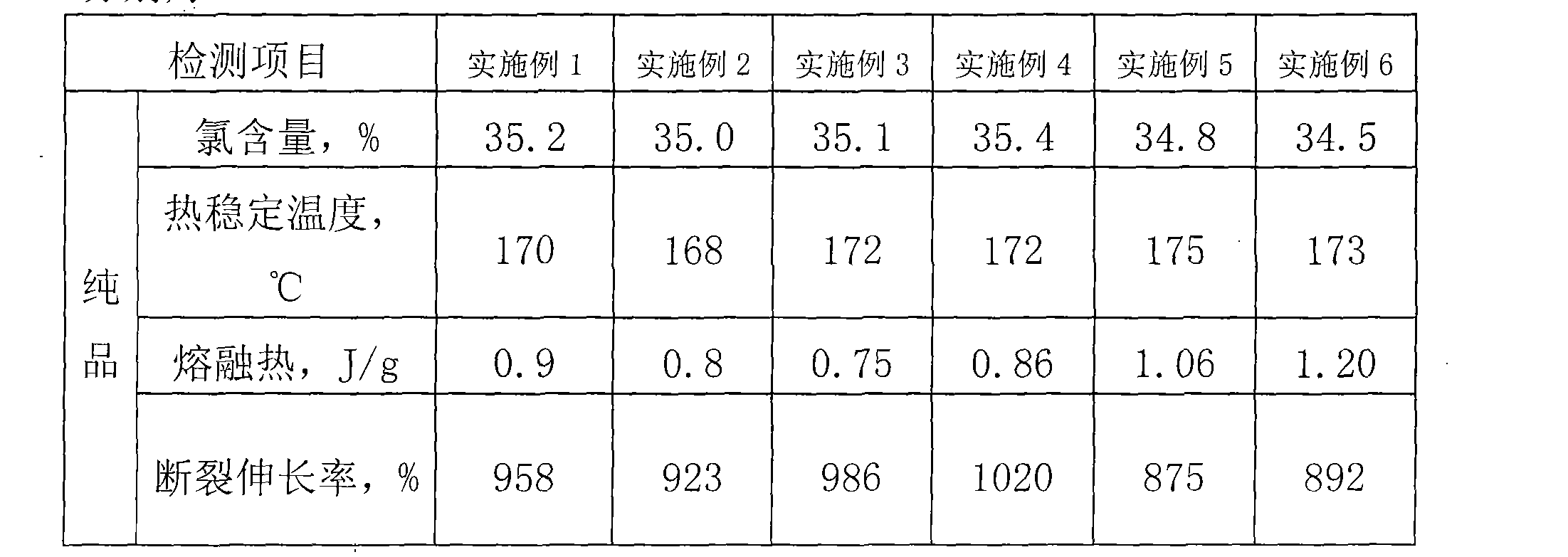

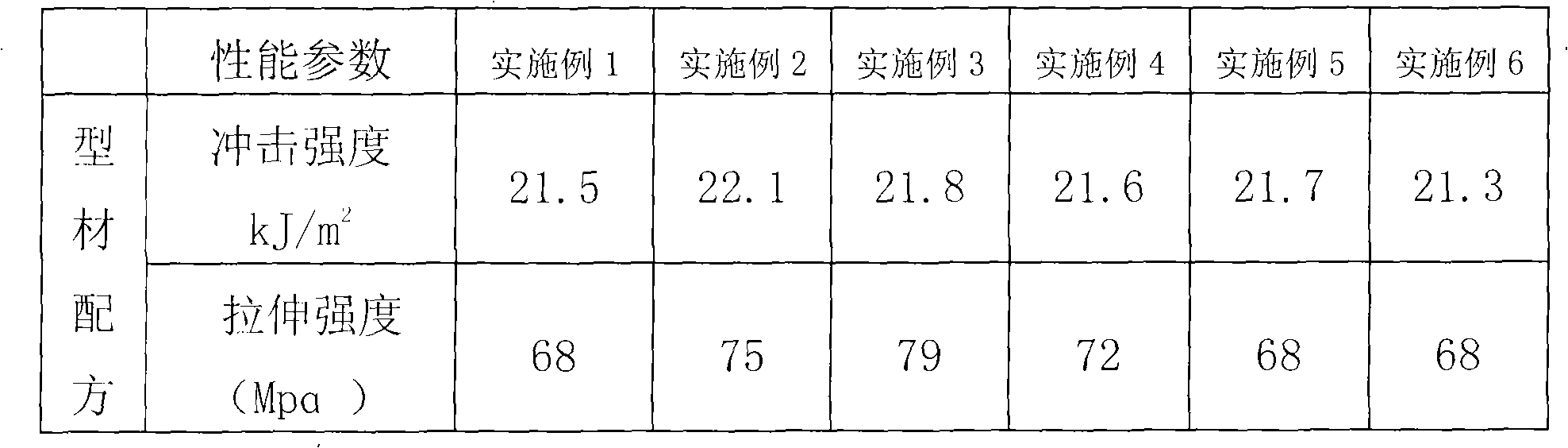

Examples

Embodiment 1

[0030] First step ingredients

[0031] Add 4,500 kilograms of water to the chlorination kettle with a capacity of 6,300 liters, and add 1.6 kilograms of dioxane, 2.6 kilograms of polyvinylpyrrolidone and 8.2 kilograms of methyl acrylate-methacrylic acid copolymer to form a dispersant, The emulsifier is composed of 0.14 kg of sodium stearate, 0.48 kg of polyoxyethylene ether and 0.48 kg of polyoxyethylene castor oil and is made of 1.6 kg of dibenzoyl peroxide and 0.2 kg of cumene peroxide. Initiator, stir for 10 minutes, then add powdered high-density polyethylene resin with a particle size of 150 mesh and 600 kg to the chlorination kettle, seal the chlorination kettle and heat it up; when the temperature in the kettle rises to 65 ° C Vacuumize until boiling; then continue to heat, and when the temperature in the kettle rises to 75°C, carry out the chlorine flow operation;

[0032] The second step of chlorine reaction

[0033] Feed 720 kg of chlorine gas into the chlorination...

Embodiment 2

[0039] First step ingredients

[0040]Add 5000 kilograms of water to the chlorination tank with a capacity of 6300 liters, add 1.2 kilograms of dioxane, 3.6 kilograms of polyvinylpyrrolidone and 9.6 kilograms of methyl acrylate-methacrylic acid copolymer to form a dispersant, The emulsifier is composed of 0.25 kg of sodium stearate, 0.36 kg of polyoxyethylene ether and 0.62 kg of polyoxyethylene castor oil and made of 1.9 kg of dibenzoyl peroxide and 0.3 kg of cumene peroxide Initiator, stir for 15 minutes, then add powdered high-density polyethylene resin with a particle size of 50 mesh and 720 kg into the chlorination kettle, seal the chlorination kettle and heat it up; when the temperature in the kettle rises to 60 ° C Vacuumize until boiling; then continue to heat, and when the temperature in the kettle rises to 75°C, carry out the chlorine flow operation;

[0041] The second step of chlorine reaction

[0042] Feed 836 kg of chlorine gas into the chlorination kettle for ...

Embodiment 3

[0048] First step ingredients

[0049] Add 5000 kilograms of water to the chlorination tank with a capacity of 6300 liters, add 1.8 kilograms of dioxane, 4.0 kilograms of polyvinylpyrrolidone and 8.4 kilograms of methyl acrylate-methacrylic acid copolymer to form a dispersant, The emulsifier is composed of 0.16 kg of sodium stearate, 0.48 kg of polyoxyethylene ether and 0.64 kg of polyoxyethylene castor oil and is made of 2.2 kg of dibenzoyl peroxide and 0.2 kg of cumene peroxide. Initiator, stir for 12 minutes, then add powdered high-density polyethylene resin with a particle size of 150 mesh and 720 kg to the chlorination kettle, seal the chlorination kettle and heat it up; when the temperature in the kettle rises to 65 ° C Vacuumize until it boils; then continue to heat, and when the temperature in the kettle rises to 80°C, carry out the chlorine flow operation;

[0050] The second step of chlorine reaction

[0051] Introduce 840 kg of chlorine gas into the chlorination k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com