Preparation method of titanium substrate surface high-temperature antioxidant composite coating

A high-temperature anti-oxidation and composite coating technology, which is applied in the direction of surface reaction electrolytic coating, coating, superimposed layer plating, etc., can solve the problem of limited improvement in high-temperature oxidation resistance of titanium or titanium alloys, and easy peeling off of anti-oxidation coatings , cumbersome preparation process, etc., to achieve the effect of improving high temperature oxidation resistance, no hole defects, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

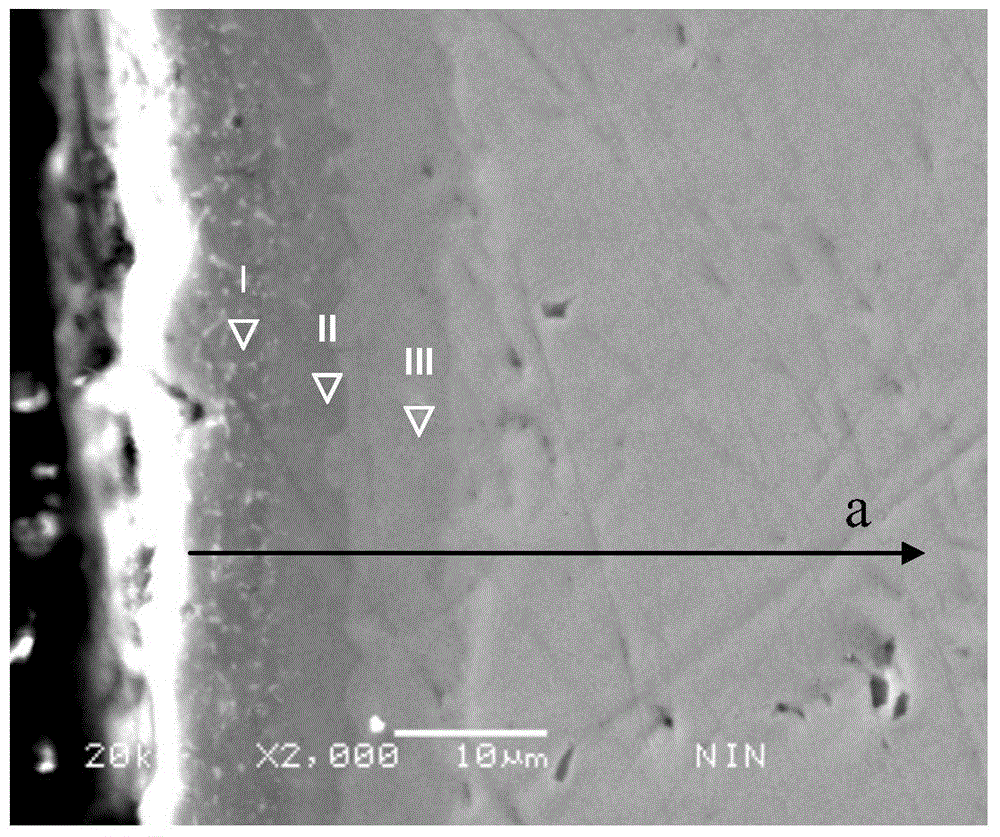

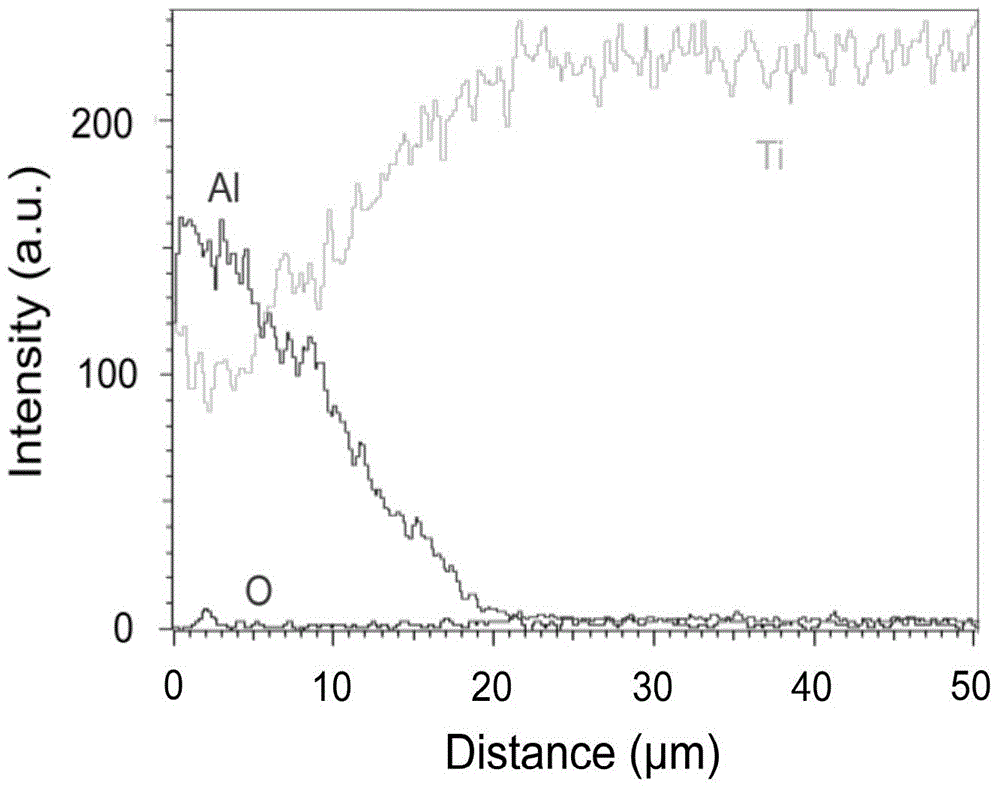

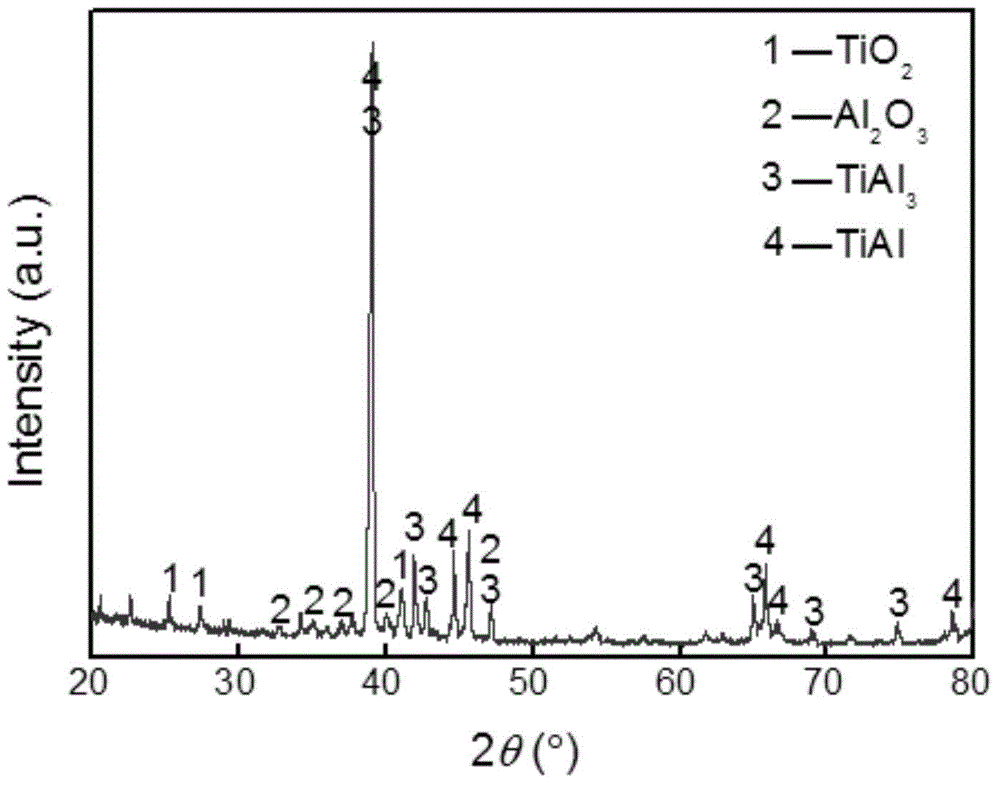

[0029] Step 1. Carry out surface polishing treatment on the titanium substrate, and then oxidize the polished titanium substrate to obtain a titanium substrate with a titanium dioxide ceramic layer on the surface, and then deposit metal aluminum on the titanium dioxide ceramic layer to obtain a titanium dioxide ceramic layer on the surface. layer and an aluminum-coated titanium substrate; the titanium substrate is pure titanium TA2, the thickness of the titanium dioxide ceramic layer is 5 μm, and the thickness of the aluminum coating is 30 μm; the method for oxidizing the titanium substrate is micro-arc oxidation, The specific process of the micro-arc oxidation is as follows: using water as a solvent to prepare a silicate system electrolyte, then placing the titanium substrate to be oxidized in the silicate system electrolyte as an anode, and a stainless steel plate as a cathode, and setting Set the micro-arc oxidation pow...

Embodiment 2

[0042] This embodiment includes the following steps:

[0043] Step 1. Carry out surface polishing treatment on the titanium substrate, and then oxidize the polished titanium substrate to obtain a titanium substrate with a titanium dioxide ceramic layer on the surface, and then deposit metal aluminum on the titanium dioxide ceramic layer to obtain a titanium dioxide ceramic layer on the surface. layer and aluminum coating titanium substrate; the titanium substrate is TC6 titanium alloy, the thickness of the titanium dioxide ceramic layer is 3 μm, and the thickness of the aluminum coating is 20 μm; the method for oxidizing the titanium substrate is atmospheric oxidation, so The specific process parameters of the atmospheric oxidation are as follows: the oxidation temperature is 600°C, and the oxidation time is 7 hours; the method for depositing the metal aluminum is vacuum magnetron sputtering deposition, and the target material selected for the vacuum magnetron sputtering deposi...

Embodiment 3

[0047] This embodiment includes the following steps:

[0048] Step 1. Carry out surface polishing treatment on the titanium substrate, and then oxidize the polished titanium substrate to obtain a titanium substrate with a titanium dioxide ceramic layer on the surface, and then deposit metal aluminum on the titanium dioxide ceramic layer to obtain a titanium dioxide ceramic layer on the surface. Layer and aluminum coated titanium substrate; the titanium substrate is pure titanium TA1, the thickness of the titanium dioxide ceramic layer is 7 μm, and the thickness of the aluminum coating is 40 μm; the oxidation is micro-arc oxidation, and the micro-arc The specific process of oxidation is: prepare a silicate system electrolyte with water as a solvent, then place the titanium substrate to be oxidized in the silicate system electrolyte as an anode, and a stainless steel plate as a cathode, set the micro-arc oxidation The power supply is a constant voltage working mode, the pulse fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com