Core-shell type polysilsesquioxane/hydroxyl acrylate composite emulsion and preparation method thereof

The technology of polysilsesquioxane and hydroxy acrylate is applied in the field of preparation of water-based polysilsesquioxane/hydroxy acrylate composite emulsion, which can solve the problems of high temperature stickiness, limited performance expansion, low temperature embrittlement and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

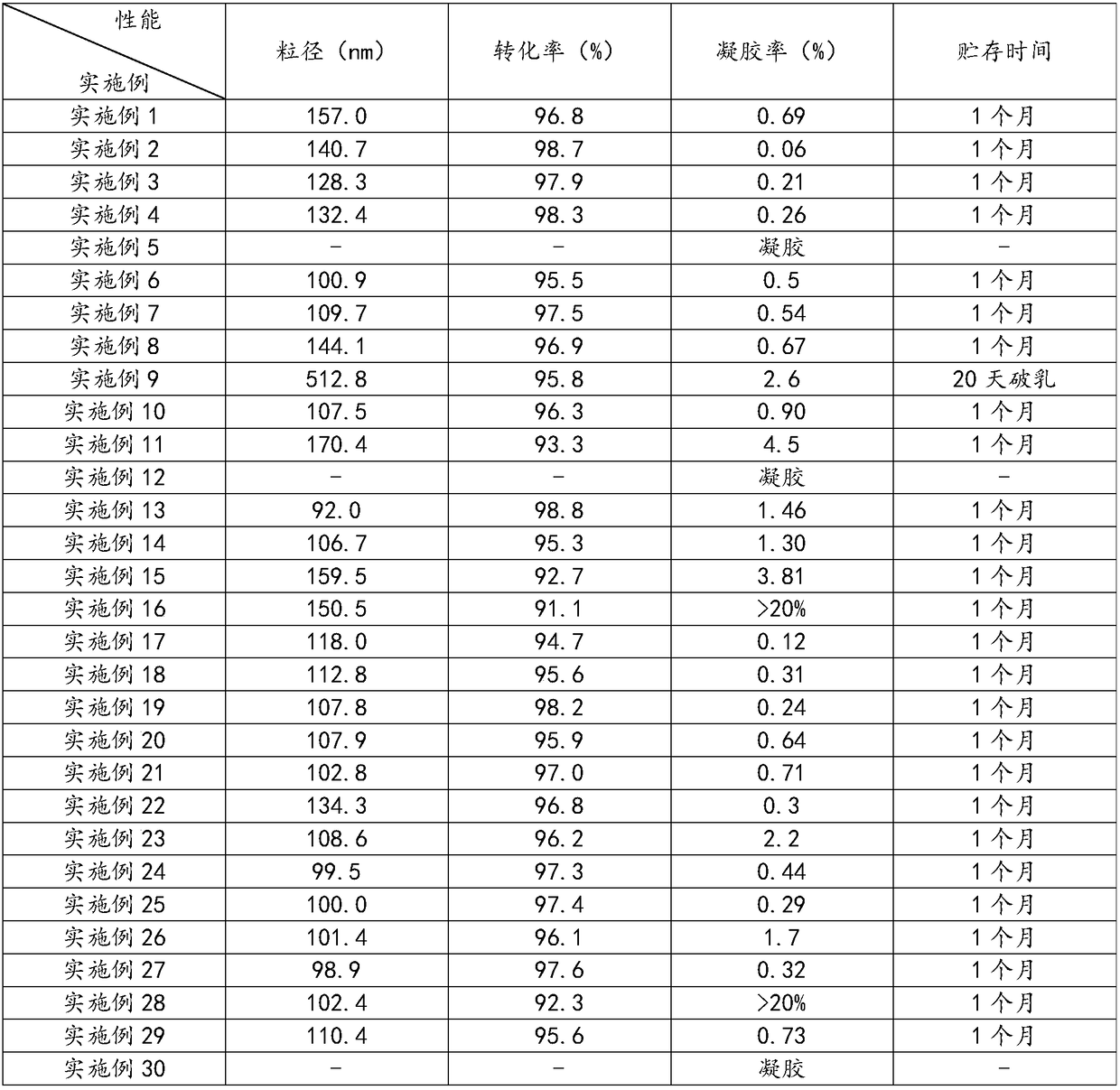

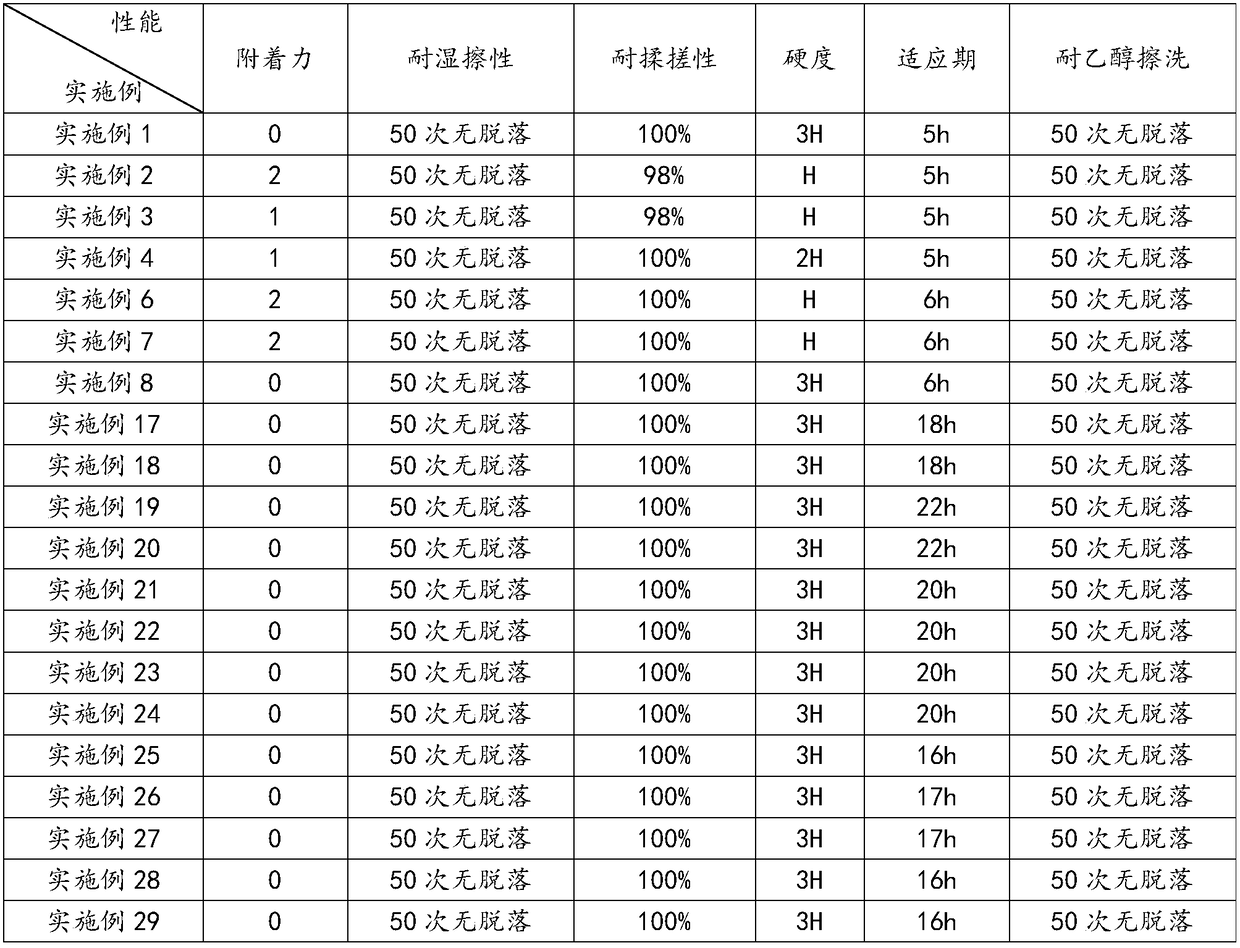

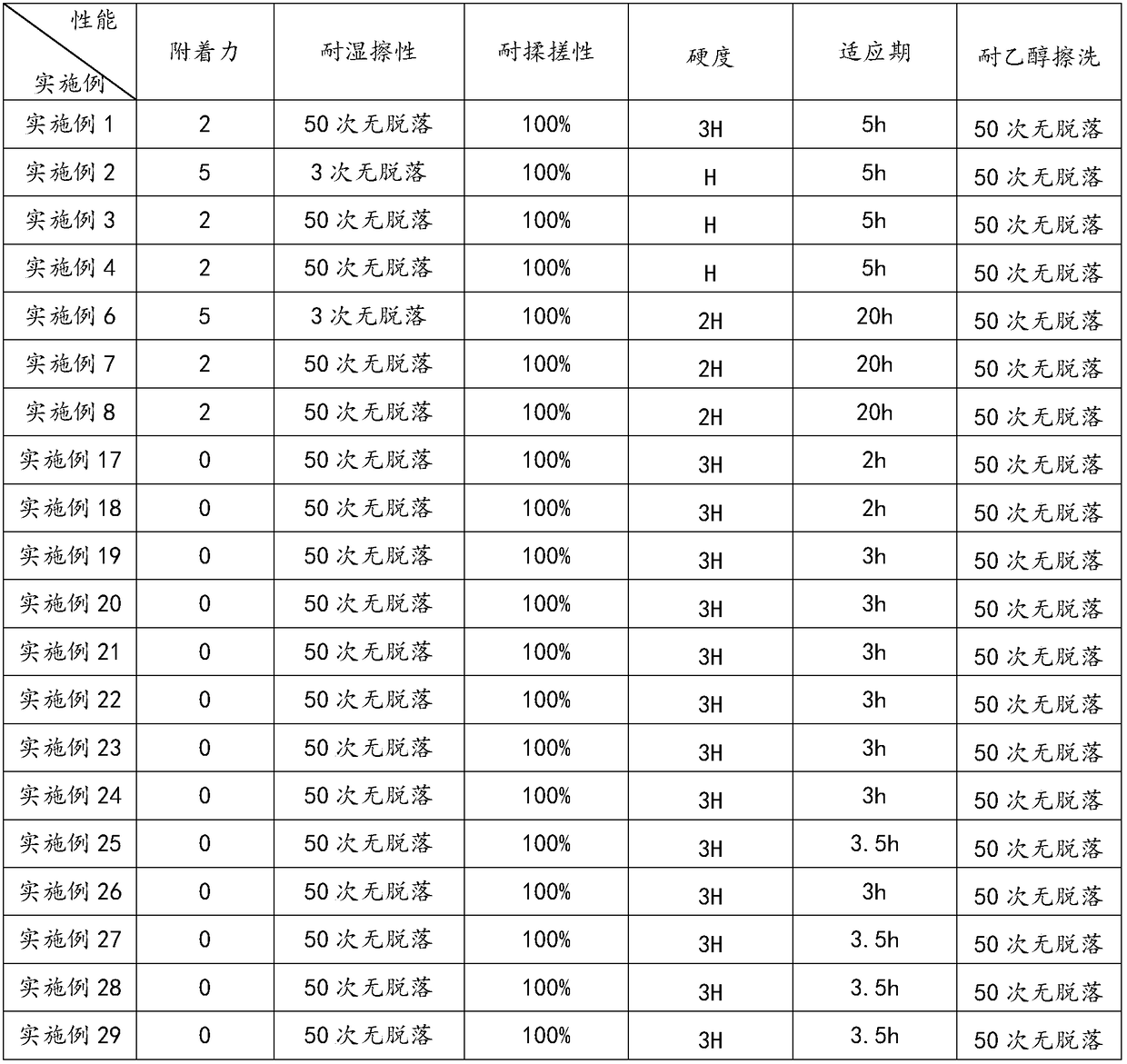

Examples

Embodiment 1

[0018] (1) Core synthesis, i.e. preparation of polysilsesquioxane emulsion:

[0019] Dissolve 0.17g of sodium hydroxide, 0.34g of dibenzoyl resorcinol and 0.17g of allyloxynonylphenol polyoxyethylene ether ammonium sulfate in 285g of water at room temperature, pour them into a reaction kettle and stir. Add 45.45g of phenyltrimethoxysilane and 4.54g of γ-methacryloxypropyltrimethoxysilane dropwise into the reaction kettle, the dropping time is 2h, and the holding time is 15h. The hydrolysis polycondensation reaction is carried out under the catalysis of the basic catalyst to obtain the silsesquioxane emulsion.

[0020] (2) Intermediate layer synthesis:

[0021] At a reaction temperature of 50° C., 7.2 g of nonylphenol polyoxyethylene ether ammonium sulfate was mixed with the polysilsesquioxane emulsion prepared in (1) and then poured into a reaction kettle. Finally, 63.60g of methyl methacrylate, 9.53g of butyl acrylate, and 2.16g of γ-methacryloxypropyltrimethoxysilane were ...

Embodiment 2

[0026] In this example, when preparing the core-shell type polysilsesquioxane / hydroxyacrylate composite emulsion, the amount of hydroxypropyl methacrylate is kept constant, and the amount of other reagents is kept constant, which is the same as in Example 1. In steps (1), (2), and (3), the ratio of the total amount of monomers is changed to 0.8:1.2:8, wherein the amount of monomers is replaced in proportion.

Embodiment 3

[0028] In this example, when preparing the core-shell polysilsesquioxane / hydroxyacrylate composite emulsion, the amount of hydroxypropyl methacrylate is kept constant, and the amount of other reagents is kept constant, which is the same as in Example 1. Step (1)(2)(3) The total monomer ratio is changed to 1.2:1.8:7, wherein the monomer amount is replaced in proportion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com