Single-component water-based silicon-fluorine modified acrylate emulsion wood lacquer and preparation method thereof

An acrylate, water-based silicon technology, applied in the direction of coating, etc., can solve the problems that the performance of nano-water-based wood paint is not well reflected, the paint film is soft, and the wear resistance is poor, and achieves excellent thermal oxidation stability, good Moisture resistance, the effect of increasing the crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

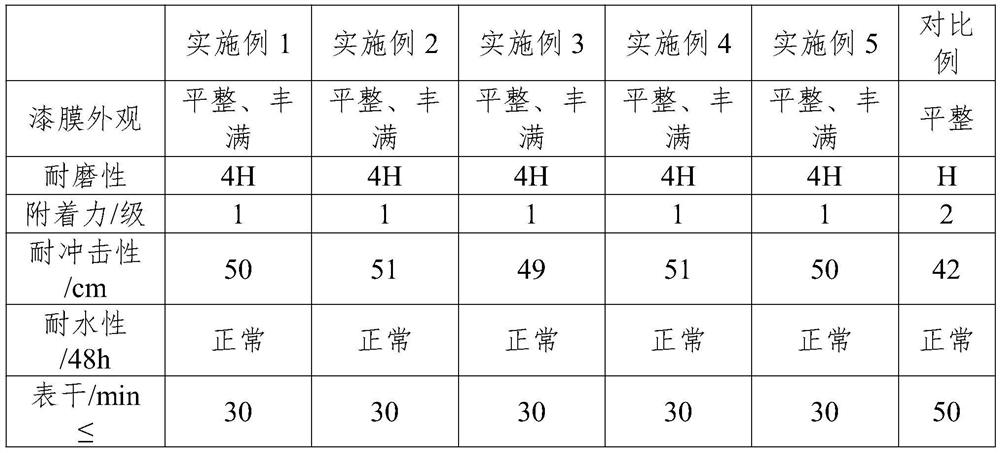

Examples

Embodiment 1

[0037] This embodiment provides a kind of preparation method of one-component water-based silicon-fluorine modified acrylate emulsion wood lacquer, comprising the following steps:

[0038] Step 1, the preparation of pre-emulsion A

[0039]In reactor A, add deionized water 100kg, anionic emulsifier 4kg, butyl acrylate 100kg, methyl methacrylate 90kg, acrylonitrile 25kg, styrene 15kg, acrylic acid 2kg, hydroxyethyl methacrylate 5kg, 800r / 341kg of pre-emulsion A was prepared by dispersing and mixing at high speed for 30 minutes;

[0040] Step 2, the preparation of organosilicon-fluorine pre-emulsion B

[0041] Into reactor B, add 60kg of pre-emulsion A obtained in step 1, 4kg of vinyltriisopropoxysilane, 5kg of silicon-fluorine modified resin, disperse and mix at 800r / min for 30min at a high speed to obtain 69kg of organosilicon-fluorine pre-emulsion B ;

[0042] Step 3, preparation of seed emulsion

[0043] Into reactor C, add 200kg of deionized water, 15kg of pre-emulsion ...

Embodiment 2

[0050] This embodiment provides a kind of preparation method of one-component water-based silicon-fluorine modified acrylate emulsion wood lacquer, comprising the following steps:

[0051] Step 1, the preparation of pre-emulsion A

[0052] In reactor A, add deionized water 90kg, anionic emulsifier 4kg, butyl acrylate 110kg, methyl methacrylate 100kg, acrylonitrile 30kg, styrene 10kg, acrylic acid 4kg, hydroxyethyl methacrylate 4kg, 1000r / 352kg of pre-emulsion A was prepared by dispersing and mixing at high speed for 20 minutes;

[0053] Step 2, the preparation of organosilicon-fluorine pre-emulsion B

[0054] Into the reaction kettle B, add 65kg of the pre-emulsion A obtained in the first step, 3kg of vinyl triisopropoxysilane, 5kg of silicon-fluorine modified resin, 800r / min high-speed dispersion and mixing for 30min to obtain 73kg of organosilicon-fluorine pre-emulsion B ;

[0055] Step 3, preparation of seed emulsion

[0056] Into reactor C, add 180kg of deionized wate...

Embodiment 3

[0063] This embodiment provides a kind of preparation method of one-component water-based silicon-fluorine modified acrylate emulsion wood lacquer, comprising the following steps:

[0064] Step 1, the preparation of pre-emulsion A

[0065] In reactor A, add deionized water 110kg, anionic emulsifier 5kg, butyl acrylate 120kg, methyl methacrylate 100kg, acrylonitrile 30kg, styrene 10kg, acrylic acid 4kg, hydroxyethyl methacrylate 4kg, 1000r / 373kg of pre-emulsion A was prepared by dispersing and mixing at high speed for 30 minutes;

[0066] Step 2, the preparation of organosilicon-fluorine pre-emulsion B

[0067] Into reactor B, add 70kg of pre-emulsion A obtained in step 1, 3kg of vinyltriisopropoxysilane, 4kg of silicon-fluorine modified resin, 1000r / min high-speed dispersion and mixing for 30min to obtain 77kg of organosilicon-fluorine pre-emulsion B ;

[0068] Step 3, preparation of seed emulsion

[0069] Into reactor C, add 200kg of deionized water, 20kg of pre-emulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com