Silicon dioxide/polyacrylate/polysiloxane composite emulsion as well as preparation method and application thereof

A technology based on acrylate and silica, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., to achieve the effect of simple operation and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

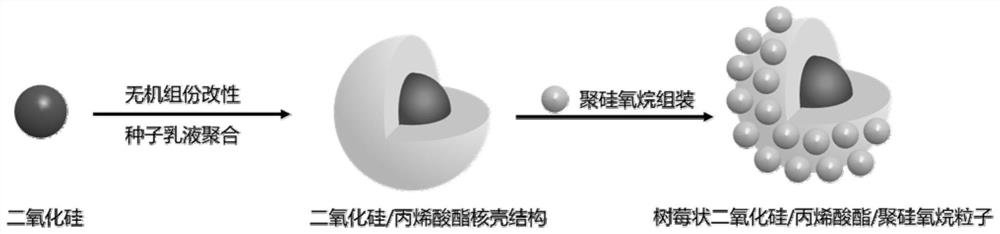

Method used

Image

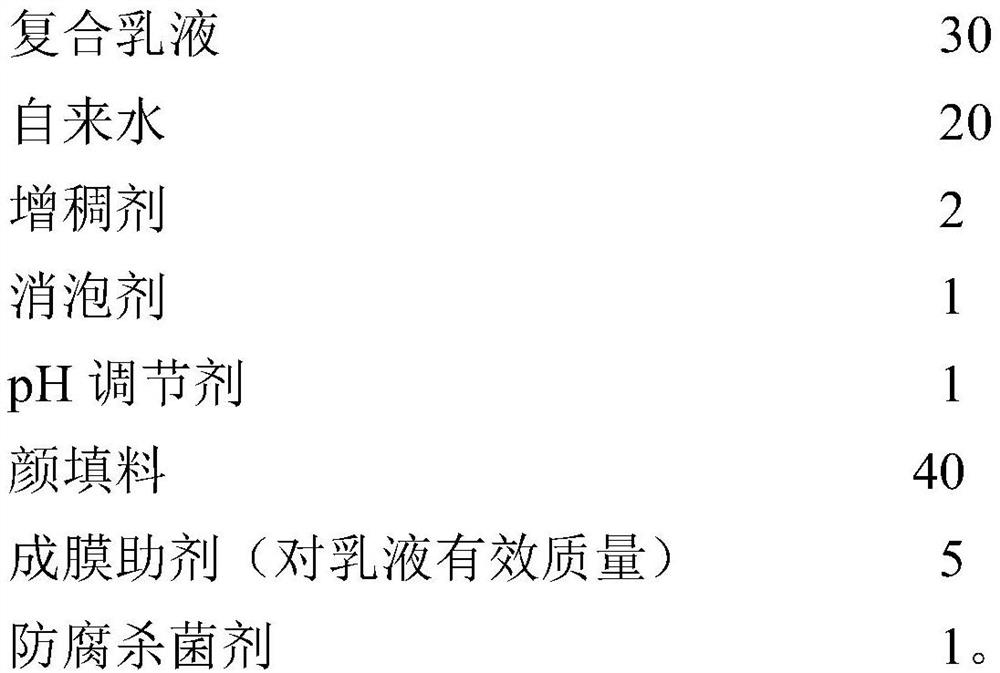

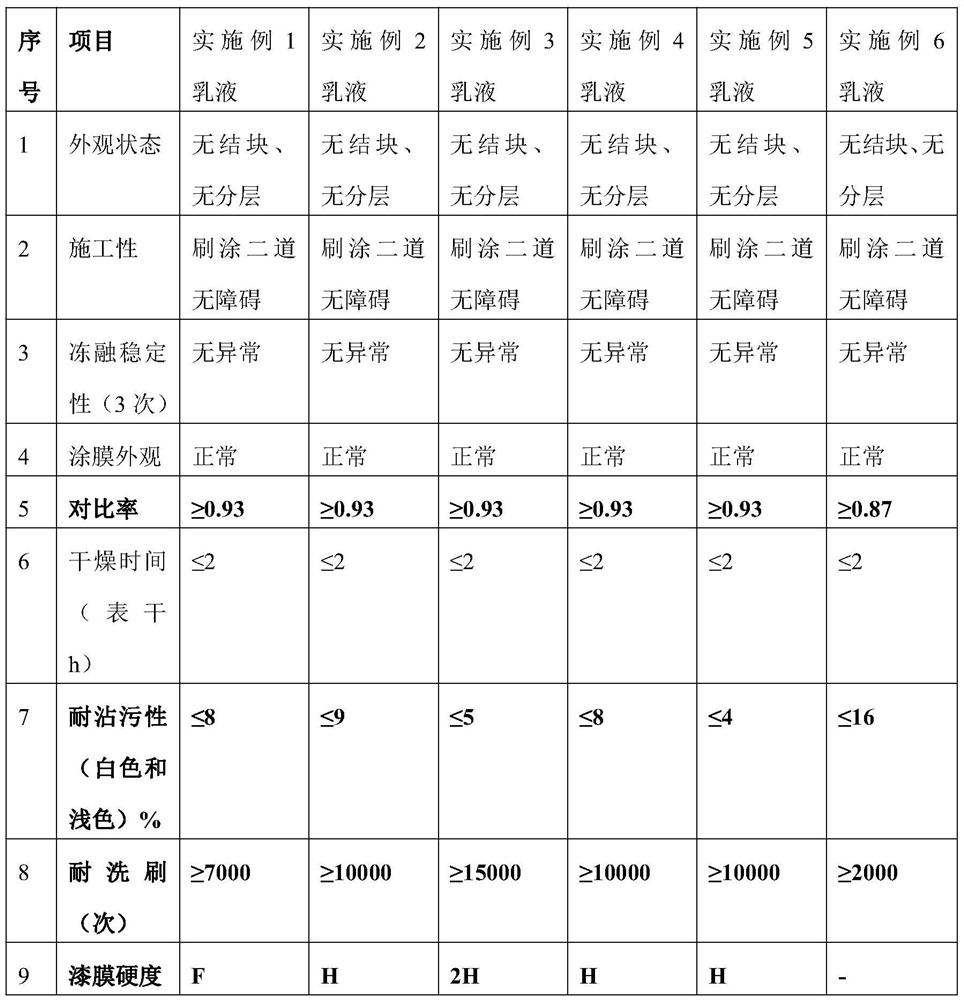

Examples

Embodiment 1

[0032] A preparation method of silica-acrylate-polysiloxane composite emulsion mainly comprises the following steps:

[0033] 1. Modification of silica sol: After mixing water and silica sol evenly, add silane coupling agent, stir at 50°C and a stirring rate of 400rpm for 6h to obtain modified silica sol; the water, silica sol and silane coupling The mass ratio of the joint agent is 1:1:0.1;

[0034] 2. Preparation of silica / acrylate core-shell structure emulsion:

[0035] ① Mix 9 parts by mass of deionized water and 0.45 parts by mass of emulsifier evenly, then slowly add 28 parts by mass of acrylic acid monomer at a stirring rate of 300 rpm, and then continue stirring for 10 minutes to form a pre-emulsion one;

[0036] ② Mix 2.25 parts by mass of deionized water and 0.11 parts by mass of emulsifier evenly, then slowly add 7 parts by mass of acrylic acid monomer and 1 part by mass of functional monomer at a stirring speed of 300 rpm, and then continue stirring for 10 minutes...

Embodiment 2

[0051] A preparation method of silica-acrylate-polysiloxane composite emulsion mainly comprises the following steps:

[0052] 1. Modification of silica sol: After mixing water and silica sol evenly, add silane coupling agent, stir at 65°C and a stirring rate of 200rpm for 3 hours to obtain modified silica sol; the water, silica sol and silane coupling The mass ratio of the joint agent is 2:2:0.03

[0053] 2. Preparation of silica / acrylate core-shell structure emulsion:

[0054] ① Mix 18 parts by mass of deionized water and 2.5 parts by mass of emulsifier evenly, then slowly add 40 parts by mass of acrylic acid monomer at a stirring rate of 600 rpm, and then continue to form a pre-emulsion for 30 minutes;

[0055] ② Mix 4.5 parts by mass of deionized water and 0.23 parts by mass of emulsifier evenly, then slowly add 10 parts by mass of acrylic acid monomer and 3 parts by mass of functional monomer at a stirring rate of 600 rpm, and then continue stirring for 30 Minutes to for...

Embodiment 3

[0070] Add 25g of deionized water to 25g of acidic silica sol (solid content 40%), raise the temperature to 60°C, add 0.6g KH570 and keep stirring at 250rpm for 5h to obtain modified silica sol (solid content 20%).

[0071] Add 20g of water, 2g of S25 and 2g of FSL 707 into a 250ml four-neck flask, stir at 250rpm at room temperature, add 1.6g of acrylic acid, 45g of methyl methacrylate and 30g of butyl acrylate, adjust the stirring speed to 400rpm, and stir for 20min to obtain Uniform and stable pre-emulsion1.

[0072] Add 6g of water, 0.3g of S25, 0.4g of FSL 707 and 0.3g of N-10 into a 100ml four-neck flask, stir well at 250rpm at room temperature, then add 0.4g of acrylic acid, 2g of methylol acryloyl urea, and 1.5g of silicone Monomer UM-1770, 2g glycidyl methacrylate, 10g methyl methacrylate and 8g butyl acrylate, adjust the stirring speed to 400rpm, and stir for 20min to obtain a uniform and stable pre-emulsion 2.

[0073] Add 5g of water and 0.2g of sodium bicarbonate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com