Styrene-acrylic emulsion for manufacturing artificial stone, preparation method, and artificial stone prepared from styrene-acrylic emulsion

A technology of artificial stone and emulsion, applied in the field of polymer chemistry and new materials, can solve the problems of large shrinkage, low flame retardancy, poor heat resistance, etc., and achieve small shrinkage, easy processing and shaping, and high weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

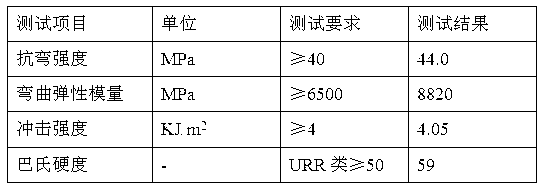

Embodiment 1

[0050] Prepare the styrene-acrylate emulsion for the manufacture of artificial stone with the following formula:

[0051] Mixed monomer 52%

[0052] Emulsifier 0.5%

[0053] Initiator 0.09%

[0054] Oxidizing agent 0.05%

[0055] Reducing agent 0.05%

[0056] water balance

[0057] The mixed monomer is made up of 90 parts of styrene, 20 parts of ethyl acrylate, 40 parts of butyl acrylate, 100 parts of isooctyl acrylate, 1 part of acrylic acid, and 2 parts of acrylamide; the emulsifier is a mass ratio of 1: 1 sodium lauryl sulfate and dodecylbenzenesulfonic acid; the initiator is ammonium persulfate and sodium persulfate with a mass ratio of 1:0.5; the oxidizing agent is butyl hydroperoxide, and the reducing agent is a mass ratio of 1 : 1 sodium sulfite and sodium dithionite.

[0058] Specific steps are as follows:

[0059] ⑴ Mix the emulsifier, one-third of the water and the mixed monomer evenly according to the formula to obtain a uniform mixed solution I;

[0060] (2...

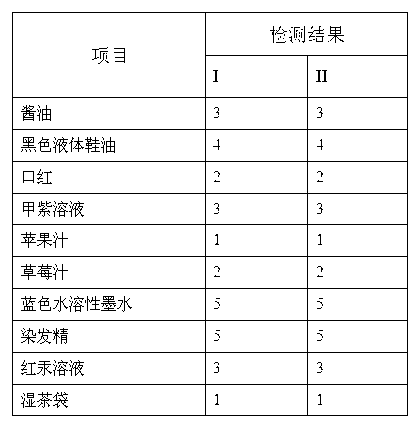

Embodiment 2

[0083] Prepare the styrene-acrylate emulsion for the manufacture of artificial stone with the following formula:

[0084] Mixed monomer 53%

[0085] Emulsifier 0.5%

[0086] Initiator 0.1%

[0087] Oxidizing agent 0.1%

[0088] Reducing agent 0.1%

[0089] water balance

[0090] The mixed monomer is composed of 95 parts of styrene, 25 parts of ethyl acrylate, 35 parts of butyl acrylate, 97 parts of isooctyl acrylate, and 1 part of acrylic acid; the emulsifier is dodecylbenzenesulfonic acid, and the initiator It is sodium persulfate, the oxidizing agent is tert-butyl hydroperoxide, and the reducing agent is sodium sulfite.

[0091] Specific steps are as follows:

[0092] ⑴ Mix the emulsifier, one-third of the water and the mixed monomer evenly according to the formula to obtain a uniform mixed solution I;

[0093] (2) Heat up the remaining two-thirds of the water to 80°C, add an initiator equivalent to 4% of the mass of the mixed solution I, keep it warm for 30 minutes, ...

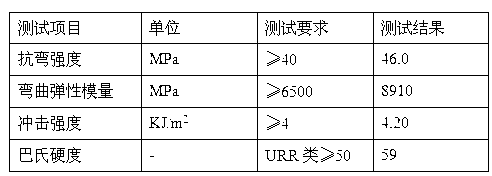

Embodiment 3

[0115] Prepare the styrene-acrylate emulsion for the manufacture of artificial stone with the following formula:

[0116] Mixed monomer 54%

[0117] Emulsifier 0.6%

[0118] Initiator 0.12%

[0119] Oxidizing agent 0.1%

[0120] Reducing agent 0.1%

[0121] water balance

[0122] The mixed monomer is composed of 100 parts of styrene, 30 parts of ethyl acrylate, 30 parts of butyl acrylate and 95 parts of isooctyl acrylate; the emulsifier is dodecylbenzenesulfonic acid, and the initiator is sodium persulfate , the oxidizing agent is tert-butyl hydroperoxide, and the reducing agent is sodium sulfite. The emulsifier is dodecylbenzenesulfonic acid, the initiator is ammonium persulfate, the oxidizing agent is tert-butyl hydroperoxide, and the reducing agent is sodium dithionite.

[0123] Specific steps are as follows:

[0124] ⑴ Mix the emulsifier, one-third of the water and the mixed monomer evenly according to the formula to obtain a uniform mixed solution I;

[0125](2) H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com