Polyester composition, and preparation method and applications thereof

A composition and polyester technology, applied in the field of polyester composition, can solve the problems of reducing polyester gel rate, low gel rate, thermal cracking, etc., and achieve easy operation, simple manufacturing process and low gel rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

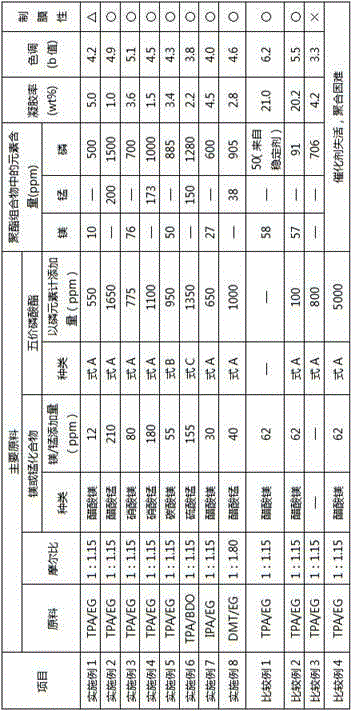

Examples

preparation example Construction

[0024] The invention also discloses a preparation method of a polyester composition. Firstly, an oligomer is obtained through esterification or transesterification of an aromatic dibasic acid or its esterified product and an aliphatic dihydric alcohol, and then the oligomer is subjected to The polyester composition is prepared by polycondensation; in the preparation process of the polyester composition, a magnesium compound or a manganese compound that is 12 to 210 ppm relative to the total amount of the polyester composition is added in terms of magnesium or manganese; In terms of phosphorus element, the total amount of the polyester composition is 550-1650ppm of the pentavalent phosphoric acid ester shown in Formula 1.

[0025] The amount of the above-mentioned pentavalent phosphoric acid ester shown in Formula 1 is preferably 775-1100 ppm equivalent to the total amount of the polyester composition in terms of phosphorus element.

[0026] The aromatic dibasic acid or its est...

Embodiment 1

[0066] At 250°C, 166 parts by weight of terephthalic acid (TPA) and 72 parts by weight of ethylene glycol (EG) (that is, the molar ratio of EG to TPA is 1.15:1) were subjected to esterification reaction, through the by-product water Production capacity, when the esterification reaction rate reaches over 97%, transfer the obtained new diethylene terephthalate (BHT) oligomers to the polymerization tank. Add stabilizer trimethyl phosphate (TMPA) equivalent to 45ppm of the total amount of the polyester composition in terms of phosphorus to the polymerization kettle in sequence, and add a regulator equivalent to 7ppm of the total amount of the polyester composition in terms of lithium elements after 5 minutes Lithium acetate (LAH), pentavalent phosphate ester (formula A) equivalent to 550ppm of the total amount of the polyester composition in terms of phosphorus, and magnesium acetate equivalent to 12ppm of the total amount of the polyester composition in terms of magnesium, after 2...

Embodiment 2

[0069] In the polycondensation stage, pentavalent phosphate (formula A) corresponding to 1650 ppm of the total amount of the polyester composition in terms of phosphorus and manganese acetate equivalent to 210 ppm of the total amount of the polyester composition in terms of manganese are added. Other steps are with embodiment 1.

[0070] During the film-making process, the polymer is bonded to the cold drum without peeling off, and the film-forming property is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com