Microreaction method and device for continuous preparation of low-dispersion acrylic resin

A technology of acrylic resin and micro-reaction device, applied in chemical instruments and methods, chemical/physical/physical chemical process, chemical/physical process, etc., can solve the limitation of acrylic resin product performance, uneven acrylic acid concentration distribution, and product molecular weight distribution. Coefficient wide and other problems, to achieve the effect of speeding up the chain initiation process, solving the problem of explosion and narrowing the particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

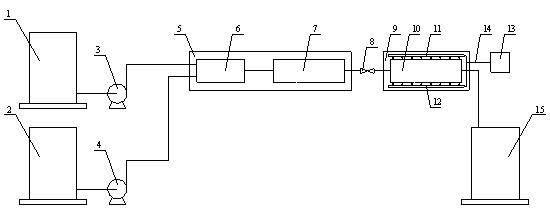

[0032] A kind of micro-reaction method for continuously preparing low-dispersion acrylic resin of the present invention comprises the following steps:

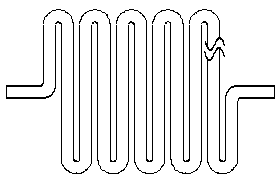

[0033] (1) The solvent is N-methylpyrrolidone with a molar concentration of 0.5mol / L acrylic acid monomer solution and a mass concentration of 0.5% benzoyl peroxide solution, which are respectively transported into a micro-mixer by a metering pump to achieve uniform mixing, wherein The molar ratio of acrylic acid monomer and initiator is 40:1, and acrylic acid monomer is acrylamide and acrylate that the molar ratio is 1:1;

[0034] (2) The mixed solution from the micro-mixer enters the delayed reaction channel, and the residence time is 3 minutes. The temperature in the micro-mixer and the delayed reaction channel is 60°C, and the reaction pressure is 0.1MPa; The reaction channel enters the quenching reaction channel, the quenching temperature is -20°C, and the mixed solution in the quenching reaction channel is ultrasonically...

Embodiment 2

[0036] A kind of micro-reaction method for continuously preparing low-dispersion acrylic resin of the present invention comprises the following steps:

[0037] (1) Transport the acrylic acid monomer solution with a molar concentration of 0.7 mol / L of dimethyl sulfoxide and the ammonium persulfate solution with a mass concentration of 1% into the micro-mixer through a metering pump to achieve uniform mixing, wherein: acrylic acid monomer The molar ratio of monomer and initiation is 60:1, and the acrylic acid monomer is a mixture of acrylamide and methacrylamide with a molar ratio of 5:1;

[0038] (2) The mixed solution from the micro-mixer enters the delayed reaction channel, the reaction residence time is 4min, the temperature in the micro-mixer and the delayed reaction channel is 70°C, and the reaction pressure is 0.2MPa; The reaction channel enters the quenching reaction channel, the quenching temperature is -15°C, and the mixed solution in the quenching reaction channel is ...

Embodiment 3

[0040] A kind of micro-reaction method for continuously preparing low-dispersion acrylic resin of the present invention comprises the following steps:

[0041] (1) The acrylic acid monomer solution with a molar concentration of dimethylacetamide of 1mol / L and the azobisisobutyronitrile solution with a mass concentration of 3% were transported into the micro-mixer through a metering pump to achieve uniform mixing, in which the acrylic acid monomer The molar ratio of monomer to initiator is 80:1, and the acrylic monomer is a mixture of acrylate and methacrylate with a molar ratio of 1:5.

[0042] (2) The mixed solution from the micro-mixer enters the delayed reaction channel again, the reaction residence time is 6 min, the temperature in the micro-mixer and the delayed reaction channel is 80°C, and the reaction pressure is 0.4 MPa; When the reaction channel enters the quenching reaction channel, the quenching temperature is -10°C, and the mixed solution in the quenching reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com