Acrylate elastic emulsion with excellent low-temperature breaking elongation and preparation method thereof

A technology of elongation at break and acrylate, which is applied in the direction of coating, etc., can solve the problems of loss of elasticity paint covering cracks, failure to achieve elastic emulsion, and decrease in elongation at break, and achieve excellent molecular chain flexibility, high elasticity, and reduced Rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

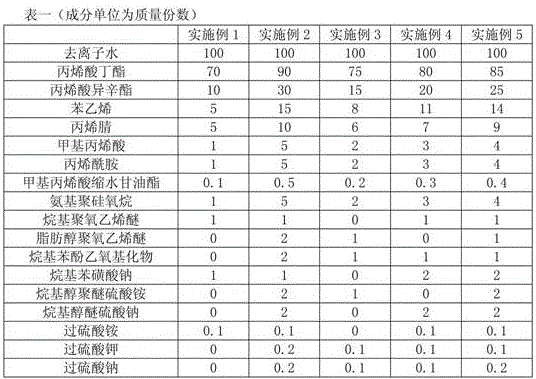

Examples

preparation example Construction

[0034] The preparation method of the acrylate elastic emulsion with excellent low temperature elongation at break of the present invention comprises the following steps:

[0035] a: Add 30-40% of the total mass of deionized water and 10-15% of the total mass of emulsifier into the reactor at normal temperature and pressure, stir evenly and raise the temperature until the temperature in the reactor reaches 75-90°C;

[0036] b: Add 30-40% of the total mass of deionized water, butyl acrylate, isooctyl acrylate, styrene, acrylonitrile, methacrylic acid, acrylamide, glycidyl methacrylate, The remaining amount of emulsifier is continuously stirred for 10-60 minutes to prepare a uniform pre-emulsion;

[0037] c: Add persulfate and the rest of deionized water into the initiator tank at normal temperature, and stir until completely dissolved into a persulfate solution for later use;

[0038] d: Maintain the temperature in the reaction kettle of step a at 75-90°C, add 5-10% of the tota...

Embodiment 1

[0046] The acrylate elastic emulsion with excellent elongation at low temperature of the present invention includes deionized water, butyl acrylate, isooctyl acrylate, styrene, acrylonitrile, methacrylic acid, acrylamide, glycidyl methacrylate, aminopoly Siloxane, emulsifier, ammonium persulfate, potassium persulfate, sodium persulfate, the above components are calculated in parts by mass: 100 parts of deionized water, 70 parts of butyl acrylate, 10 parts of isooctyl acrylate, benzene 5 parts of ethylene, 5 parts of acrylonitrile, 1 part of methacrylic acid, 1 part of acrylamide, 0.1 part of glycidyl methacrylate, 1 part of amino polysiloxane, 2 parts of emulsifier, 0.1 part of ammonium persulfate.

[0047] The emulsifiers include nonionic emulsifiers and anionic emulsifiers, and the molar ratio of nonionic emulsifiers to anionic emulsifiers is 1:1.

[0048] The nonionic emulsifier is an alkyl polyoxyethylene ether, and its content is calculated in parts by mass: 1 part of alk...

Embodiment 2

[0061] The acrylate elastic emulsion with excellent elongation at low temperature of the present invention includes deionized water, butyl acrylate, isooctyl acrylate, styrene, acrylonitrile, methacrylic acid, acrylamide, glycidyl methacrylate, aminopoly Siloxane, emulsifier, ammonium persulfate, potassium persulfate, sodium persulfate, the above components are calculated in parts by mass: 100 parts of deionized water, 90 parts of butyl acrylate, 30 parts of isooctyl acrylate, benzene 15 parts of ethylene, 10 parts of acrylonitrile, 5 parts of methacrylic acid, 5 parts of acrylamide, 0.5 parts of glycidyl methacrylate, 5 parts of aminopolysiloxane, 10 parts of emulsifier, 0.1 part of ammonium persulfate, persulfuric acid Potassium 0.2 part, sodium persulfate 0.2 part.

[0062] The emulsifiers include nonionic emulsifiers and anionic emulsifiers, and the molar ratio of nonionic emulsifiers to anionic emulsifiers is 1:1.

[0063] The nonionic emulsifier is a mixture of alkyl po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com