Organic silicon modified acrylic emulsion and preparation method thereof

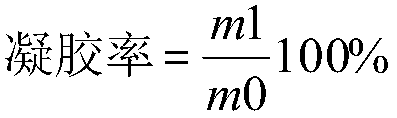

An acrylic emulsion and silicone technology, applied in the field of new materials, can solve the problems of limited use range, high temperature viscosity, poor water resistance, etc., and achieve the effects of good mechanical stability, improved water resistance, and low gel rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

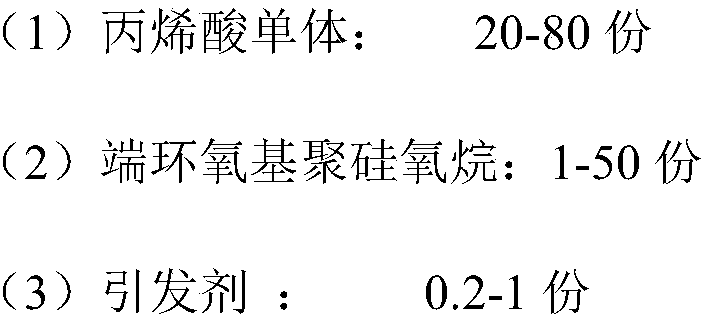

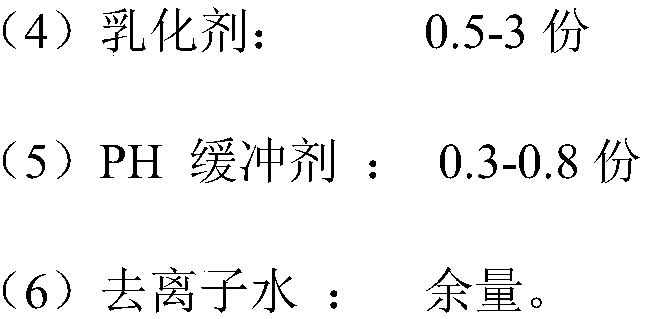

Method used

Image

Examples

Embodiment 1

[0029] The emulsion of the present invention includes water, methyl methacrylate, n-butyl acrylate, acrylic acid, hydroxyethyl acrylate, epoxy-terminated polydimethylsiloxane, allyloxy fatty alcohol oxyethylene ether ammonium sulfate, peroxide Ammonium sulfate, and a pH regulator. The contents of the above components are calculated in parts by mass: 55 parts of water; 20 parts of methyl methacrylate; 20 parts of n-butyl acrylate; 3 parts of acrylonitrile; 1 part of acrylic acid; 1 part of hydroxyethyl acrylate; 2 parts of base polydimethylsiloxane, 5.8 parts of allyloxy fatty alcohol oxyethylene ether ammonium sulfate, 1 part of ammonium persulfate, and 0.5 parts of pH regulator.

[0030] The preparation method of the present invention comprises the following steps:

[0031] Stir 19 parts of n-butyl acrylate, 19 parts of methyl methacrylate and 2 parts of single-ended epoxy polydimethylsiloxane evenly to obtain a mixture with a viscosity of 20 mPa·s at 25°C; among them, the e...

Embodiment 2

[0042] The emulsion of the present invention comprises water, styrene, n-butyl acrylate, acrylic acid, hydroxyethyl acrylate, epoxy-terminated polydimethylsiloxane, allyloxy fatty alcohol oxyethylene ether ammonium sulfate, ammonium persulfate, and pH regulators. The contents of the above components are calculated in parts by mass: 55 parts of water; 20 parts of styrene; 20 parts of n-butyl acrylate; 3 parts of acrylonitrile; 1 part of acrylic acid; 1 part of hydroxyethyl acrylate; 5 parts of methyl siloxane, 6.2 parts of allyloxy fatty alcohol oxyethylene ether ammonium sulfate, 1 part of ammonium persulfate, and 0.5 parts of pH regulator.

[0043] The preparation method of the present invention comprises the following steps:

[0044] Stir 19 parts of styrene, 19 parts of n-butyl acrylate and 5 parts of epoxy-terminated polydimethylsiloxane evenly to obtain a mixture with a viscosity of 20 mPa·s at 25°C; among them, epoxy-terminated polydimethylsiloxane The epoxy group mass...

Embodiment 3

[0052] The emulsion of the present invention comprises water, styrene, n-butyl acrylate, acrylic acid, hydroxyethyl acrylate, epoxy-terminated polydimethylsiloxane, allyloxy fatty alcohol oxyethylene ether ammonium sulfate, ammonium persulfate, and pH regulators. The contents of the above components are calculated in parts by mass: 55 parts of water; 20 parts of styrene; 20 parts of n-butyl acrylate; 3 parts of acrylonitrile; 1 part of acrylic acid; 1 part of hydroxyethyl acrylate; 7 parts of methyl siloxane, 6.9 parts of allyloxy fatty alcohol oxyethylene ether ammonium sulfate, 1 part of ammonium persulfate, and 0.6 parts of pH regulator.

[0053]The preparation method of the present invention comprises the following steps:

[0054] Stir 19 parts of styrene, 19 parts of n-butyl acrylate and 7 parts of epoxy-terminated polydimethylsiloxane evenly to obtain a mixture with a viscosity of 20 mPa·s at 25°C; among them, epoxy-terminated polydimethylsiloxane The mass content of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com