Modified vinyl ester resin and preparation method thereof, toughened and modified vinyl ester resin with good air-drying property, and preparation method and application of toughened and modified vinyl ester resin

A vinyl ester resin, toughening modification technology, applied in the field of vinyl ester resin and preparation, to achieve the effects of increasing toughness, reducing gel rate and increasing molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the modified vinyl ester resin of the present embodiment may further comprise the steps:

[0032] In the reactor, drop into 47g bisphenol A type epoxy resin E-44 (epoxy equivalent 227.27), 16g acrylic acid, the polymerization inhibitor hydroquinone of raw material gross mass 0.028%, stir at 45 ℃, then slowly Drop into 7g toluene diisocyanate, the catalyst dibutyltin dilaurate of 0.1% of raw material gross mass, be heated up to 70 ℃ and react, react 2h, add the catalyst benzyltriethylammonium chloride of raw raw material gross mass 0.6% afterwards, and heat up to React at 110°C until the acid value drops below 15mgKOH / g, then lower the temperature to 80°C, add 30g of active diluent styrene, until the mixture is uniform, and a light yellow transparent vinyl ester resin is obtained.

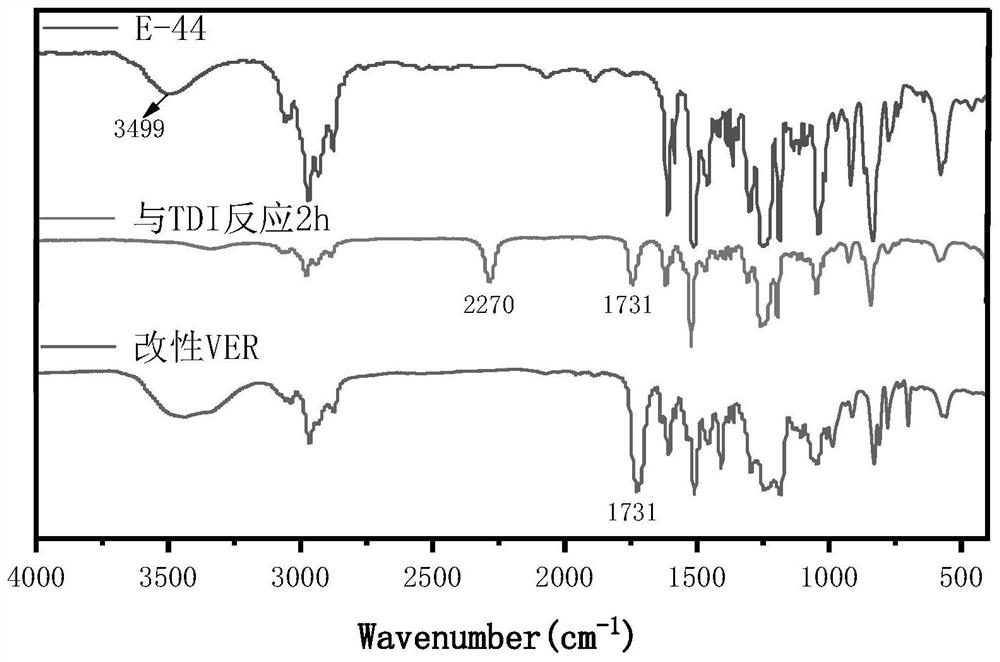

[0033] The Nicolet iS10 Fourier Transform Infrared Spectrometer of Thermo Fisher was used to monitor and analyze the functional groups in real time during the synthe...

Embodiment 2

[0036] The preparation method of the modified vinyl ester resin of the present embodiment may further comprise the steps:

[0037] (1) In the reactor, drop into 49g bisphenol A type epoxy resin E-44 (epoxy equivalent 227.27), 15g acrylic acid, the polymerization inhibitor hydroquinone of raw material gross mass 0.028%, stir at 45 ℃ , then slowly drop into 5g toluene diisocyanate, catalyzer dibutyltin dilaurate of 0.1% of the total mass of raw materials, be warming up to 70°C for reaction, react for 2h, then add benzyltriethylammonium chloride and benzyltriethylammonium chloride of 0.6% of the total mass of raw materials 1g of fumaric acid, stir until fully dissolved, heat up to 110°C for reaction until the acid value drops below 15mgKOH / g, then lower the temperature to 80°C, add 30g of reactive diluent styrene, until the mixture is uniform, and a light yellow color is obtained Transparent vinyl ester resin.

[0038] The same analysis method as in Example 1 was used to monitor a...

Embodiment 3

[0040] The preparation method of the toughened and modified vinyl ester resin with good air-drying property of the present embodiment comprises the following steps:

[0041] (1) Under the environment of nitrogen protection, drop into 30g of toluene diisocyanate and 45g of castor oil in the reactor and mix evenly, heat up to 45°C for 3h, then add 25g of hydroxyethyl acrylate, 0.1% of the total mass of raw materials Catalyst II Dibutyltin laurate and 0.1% of the total mass of raw materials as a polymerization inhibitor hydroquinone were heated up to 78° C. for 4 hours and stirred evenly to obtain a clear and transparent castor oil-based urethane acrylate resin.

[0042] (2) In another reactor, drop into 47g bisphenol A type epoxy resin E-44 (epoxy equivalent 227.27), 16g acrylic acid, the stopper hydroquinone of raw material gross mass 0.028%, at 45 ℃ Stir evenly, then slowly add 7g of toluene diisocyanate, a catalyst of 0.1% of the total mass of raw materials, dibutyltin dilaur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com