Waterborne silicone acrylate emulsion with core-shell structure and preparation method of waterborne silicone acrylate emulsion

A core-shell structure, water-based silicon technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve problems such as hot stickiness, cold brittleness, water resistance, poor development and application, and poor heat resistance , to achieve the effects of improving moldability, lowering the minimum film forming temperature, and lowering the gel rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of pre-emulsion: Add 48 parts by mass of deionized water and 1 part by mass of emulsifier into a four-neck flask, stir evenly, slowly add 12.5 parts by mass of MMA, 41.4 parts by mass of BA, and stir at high speed for 30 minutes to obtain the nucleus Pre-emulsion: Add 32 parts by mass of deionized water and 1 part by mass of emulsifier in another four-necked flask, stir evenly, slowly add 26 parts by mass of MMA, 14 parts by mass of BA, 2 parts by mass of AA, and stir at high speed for 30 minutes. Acquired shell pre-emulsion.

[0034] (2) Preparation of nuclear emulsion: In a four-neck flask equipped with a stirrer, a condenser, and a thermometer, 30 parts by mass of deionized water, 1 part by mass of emulsifier, and 0.5 parts by mass of buffer sodium bicarbonate were added under nitrogen protection. After stirring evenly, add 1.5 parts by mass of MMA, 4.6 parts by mass of BA, and an aqueous initiator solution, and gradually raise the temperature to 80°C...

Embodiment 2

[0044] (1) Preparation of pre-emulsion; Add 42 parts by mass of deionized water and 0.5 parts by mass of emulsifier in a four-necked flask, stir evenly, slowly add 12.5 parts by mass of MMA, 41.4 parts by mass of BA, stir at high speed for 30min, and obtain the nucleus Pre-emulsion: Add 28 parts by mass of deionized water and 0.5 parts by mass of emulsifier in another four-necked flask, stir evenly, slowly add 26 parts by mass of MMA, 14 parts by mass of BA, 3 parts by mass of AA, and stir at high speed for 30 minutes. Acquired shell pre-emulsion.

[0045] (2) Preparation of nuclear emulsion: In a four-necked flask equipped with a stirrer, a condenser, and a thermometer, 26.25 parts by mass of deionized water, 0.5 parts by mass of emulsifier, and 0.4 parts by mass of buffer sodium bicarbonate were added under nitrogen protection. After stirring evenly, add 1.5 parts by mass of MMA, 4.6 parts by mass of BA, and an aqueous initiator solution, and gradually raise the temperature ...

Embodiment 3

[0049] (1) Preparation of pre-emulsion; Add 45 parts by mass of deionized water and 0.8 parts by mass of emulsifier in a four-necked flask, stir evenly, slowly add 15.63 parts by mass of MMA, 34.5 parts by mass of BA, stir at high speed for 30min, and obtain the nucleus Pre-emulsion; in another four-necked flask, add 30 parts by mass of deionized water and 0.8 parts by mass of emulsifier, stir evenly, slowly add 32.5 parts by mass of MMA, 11.67 parts by mass of BA, 4 parts of AA, stir at high speed for 30min, and obtain Shell pre-emulsion.

[0050] (2) Preparation of nuclear emulsion: In a four-necked flask equipped with a stirrer, a condenser, and a thermometer, 28.13 parts by mass of deionized water, 0.8 parts by mass of emulsifier, and 0.4 parts by mass of buffer sodium bicarbonate were added under nitrogen protection. After stirring evenly, add 1.75 parts by mass of MMA, 3.83 parts by mass of BA, and an aqueous initiator solution, and gradually raise the temperature to 85°...

PUM

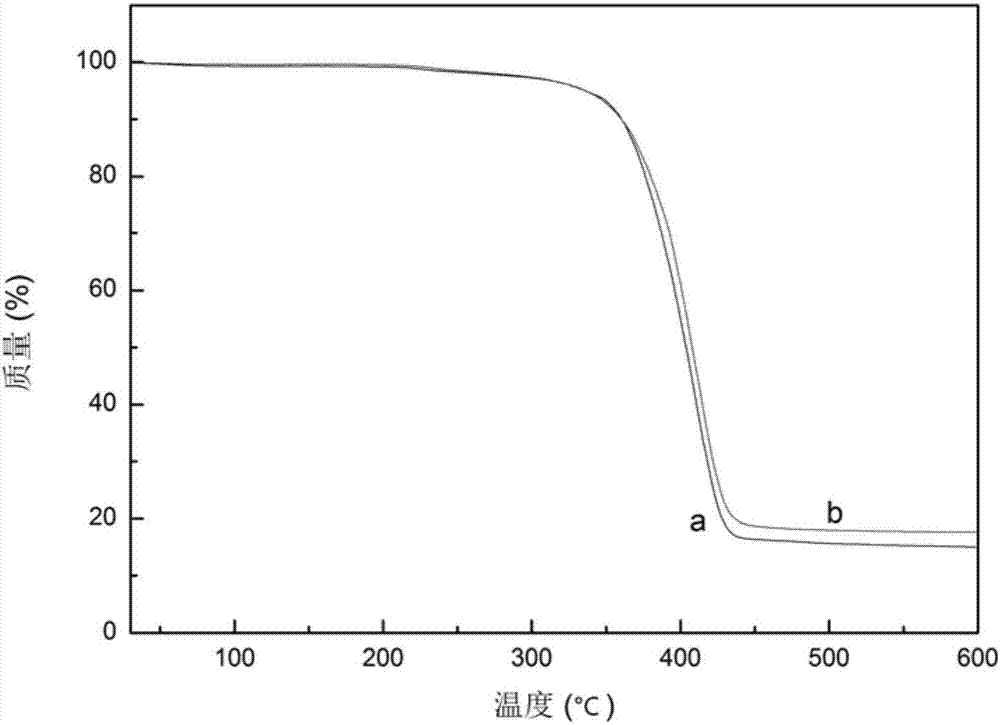

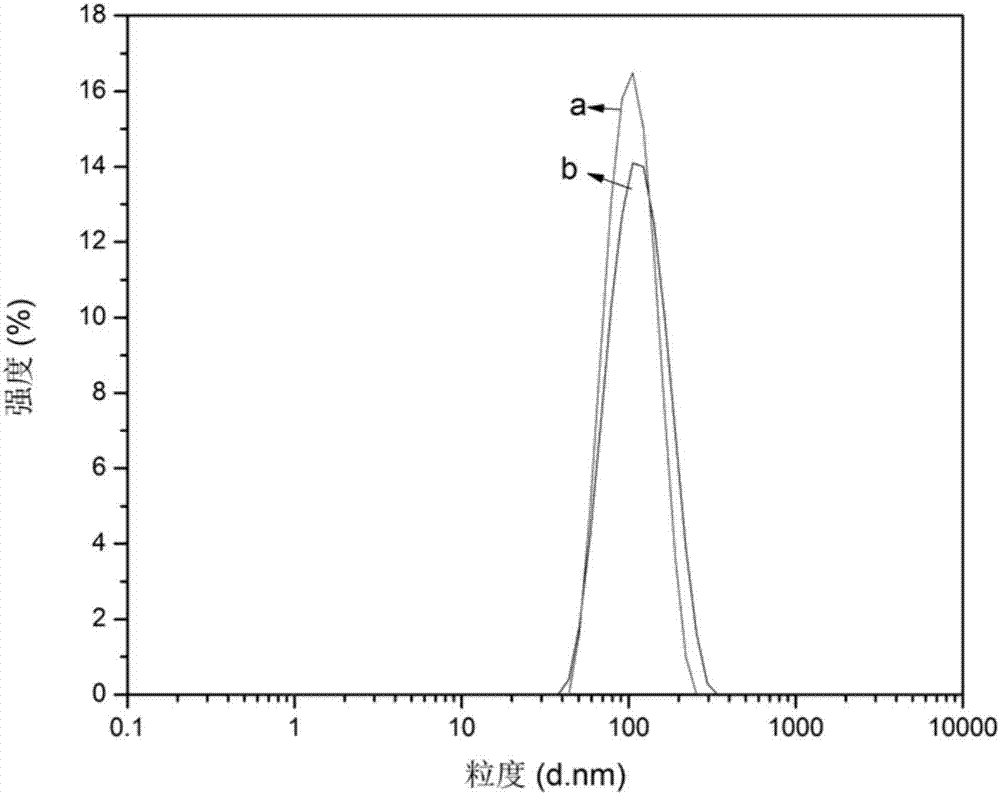

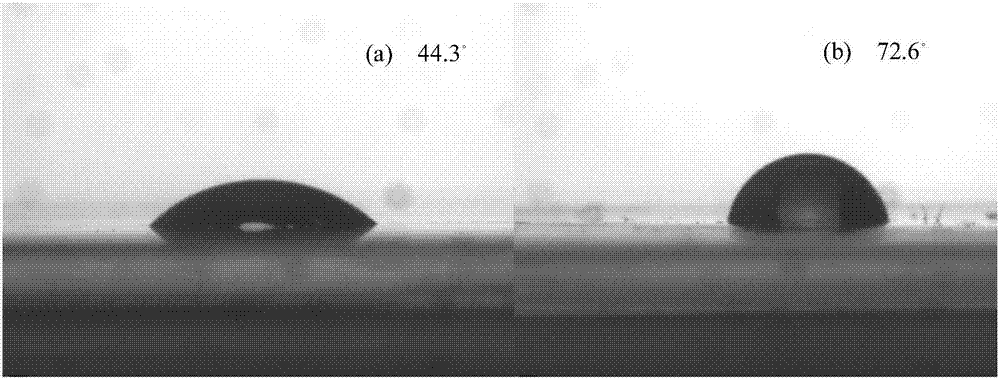

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com