Dual-reflection zone cholesteric liquid crystal film with reversible light response characteristic and preparation method for dual-reflection zone cholesteric liquid crystal film

A cholesteric liquid crystal, double-reflection technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems that the film does not have the performance of reversible light regulation, the film preparation method is complicated, and the yield is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

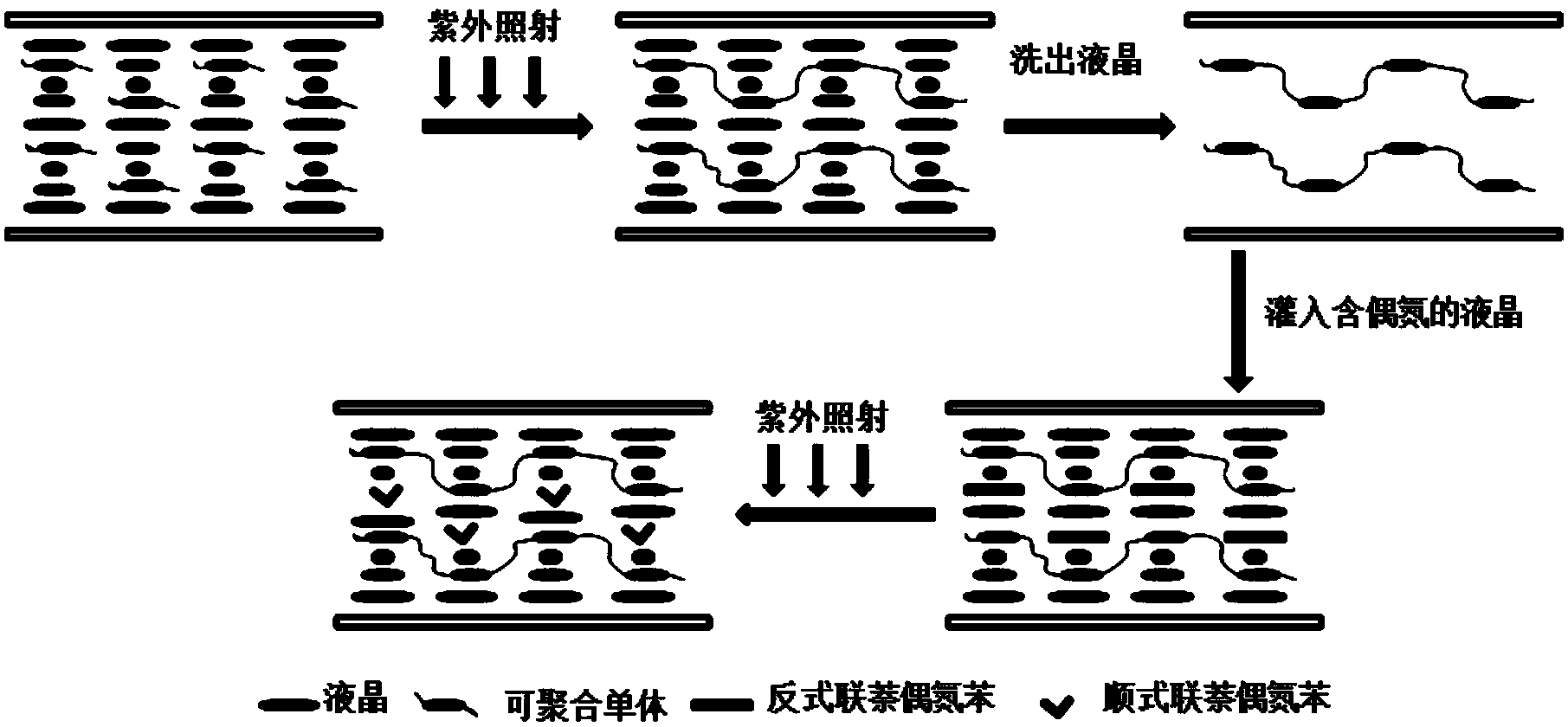

[0041] like figure 1 As shown, a method for preparing a double-reflection band cholesteric liquid crystal film with reversible photoresponse characteristics, the shown method includes the following steps:

[0042] 1) In terms of mass percentage, mix S811110%, polymerizable monomer C6M25%, nematic liquid crystal slc171764.25% and benzoin dimethyl ether 0.75%;

[0043] 2) injecting the compounded liquid crystal system obtained in step 1) into a liquid crystal cell with a thickness of 25 microns in advance at 45° C. to obtain a film before polymerization;

[0044] 3) the film sample before polymerization prepared in step 2) is 365nm with wavelength in the temperature range of cholesteric phase, and intensity is 10mW / cm 2 UV light is irradiated and polymerized for 30 minutes to obtain a polymerized film with a polymer network formed inside;

[0045] 4) Soak the polymerized film sample in step 3) in cyclohexane to wash out unreacted small molecule liquid crystals to obtain a wash...

Embodiment 2

[0055] like figure 1 As shown, a method for preparing a double-reflection band cholesteric liquid crystal film with reversible photoresponse characteristics, the shown method includes the following steps:

[0056] 1) In terms of mass percentage, 20% of polymerizable monomer DCM, nematic liquid crystal slc171779% and 1% of benzoin dimethyl ether are mixed;

[0057] 2) injecting the compounded liquid crystal system obtained in step 1) into a liquid crystal cell with a thickness of 25 micrometers which has been pre-parallel-oriented at 45° C. to obtain a corresponding film before polymerization;

[0058] 3) the film sample before polymerization prepared in step 2) is 365nm with wavelength in the temperature range of cholesteric phase, and intensity is 10mW / cm 2 UV light is irradiated and polymerized for 30 minutes to obtain a polymerized film with a polymer network formed inside;

[0059] 4) Soak the polymerized film sample in step 3) in cyclohexane to wash out unreacted small ...

Embodiment 3

[0067] like figure 1 As shown, a method for preparing a double-reflection band cholesteric liquid crystal film with reversible photoresponse characteristics, the shown method includes the following steps:

[0068] 1) In terms of mass percentage, mix S811115%, polymerizable monomer C6M20%, nematic liquid crystal slc701164.5% and 0.5% benzoin dimethyl ether;

[0069] 2) injecting the compounded liquid crystal system obtained in step 1) into a liquid crystal cell with a thickness of 25 micrometers which has been pre-parallel-oriented at 45° C. to obtain a corresponding film sample before polymerization;

[0070] 3) the film sample before polymerization prepared in step 2) is 365nm with wavelength in the temperature range of cholesteric phase, and intensity is 10mW / cm 2 UV light was irradiated for 30 minutes and polymerized to obtain a polymerized film sample with a polymer network formed inside;

[0071] 4) Soak the polymerized film sample in step 3) in cyclohexane to wash out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com