Method for preparing dielectric film embedded with high-density palladium nano-crystal

A dielectric thin film, palladium nanotechnology, applied in the field of semiconductor memory manufacturing, can solve the problems of difficult control of nanocrystal size and distribution, limited surface density of nanocrystals, etc., achieve good charge storage effect, low rapid thermal annealing temperature, reduce Effects of thermal damage and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

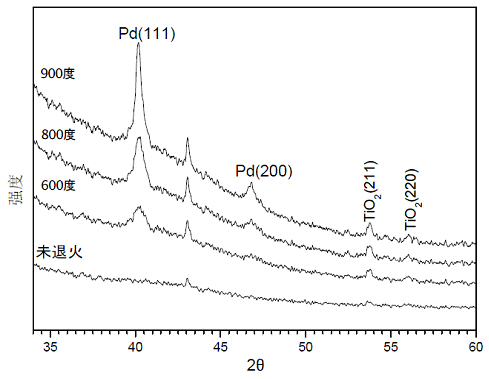

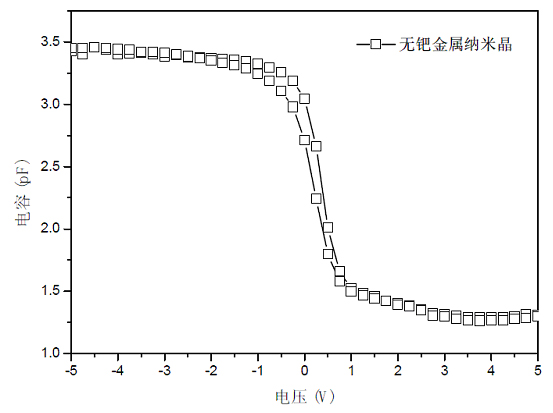

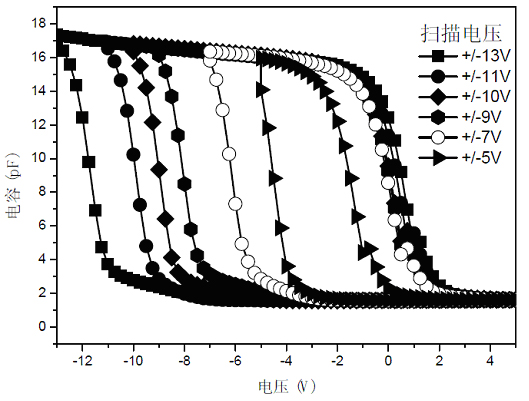

[0023] After standard cleaning of P-type (100) silicon wafers, a layer of Al with a thickness of about 6nm was grown by atomic layer deposition (ALD) 2 o 3 thin film, as a charge tunneling layer. Put the silicon wafer covered with the above film into the magnetron sputtering reaction chamber, and the two targets for co-sputtering are Pd and Ti. The sputtering condition is: chamber vacuum degree 4.2×10 -5 Pa, argon (Ar) flow rate is 37sccm, oxygen (O 2 ) flow rate is 4 sccm, the DC power applied to the Pd target and Ti target is 25W and 100W respectively, the working pressure is 0.72Pa, the substrate is not heated, the substrate rotation speed is 8 rpm, and the total sputtering time is 840 seconds. Test analysis shows that the film obtained by co-sputtering method is palladium oxide (PdO x ) and titanium oxide (TiO x ) of the mixed film. Next, put the obtained sample into a rapid thermal annealing furnace for rapid thermal annealing, and the annealing atmosphere is nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com