Waste gas treatment device for industrial adhesive product production

An exhaust gas treatment device and industrial glue technology, which is applied in the direction of combination device, transportation and packaging, fixed filter element filter, etc., can solve the problems of lack of exhaust gas particles, inconvenient particle treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

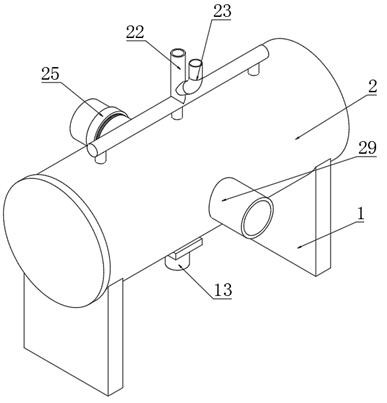

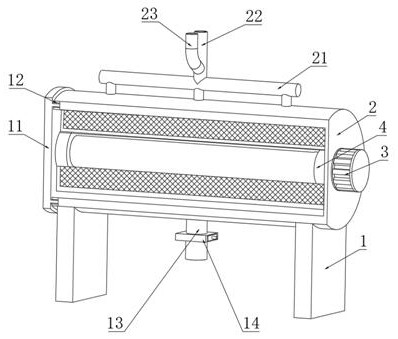

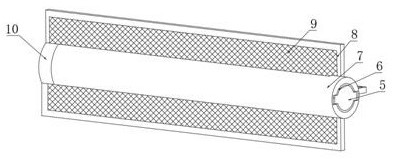

[0036] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a waste gas treatment device for the production of industrial adhesive products, including a support frame 1, a treatment tank 2 is placed on the top of the support frame 1, and the outer end of the treatment tank 2 is fixedly connected with an inlet An air pipe 29, a motor 3 is installed at the center of one end of the processing tank 2, a snap-in barrel 4 is fixedly connected to the center of the inner wall of the processing tank 2, the output shaft of the motor 3 is fixedly connected to a fixed rod 5, and the outer end of the fixed rod 5 passes through the card slot 6 A connecting rod 7 is clamped, and the outer end of the connecting rod 7 is symmetrically fixedly connected to a mounting frame 8, the inner wall of the mounting frame 8 is embedded with a first filter screen 9, one end of the connecting rod 7 is connected to a connecting block 10 in rotation, and one end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com