Continuously reinforced plastic heat-preserving composite pipeline used for oil field ground and its manufacturing technique

A technology of reinforced plastic and composite pipes, which is applied in the direction of pipes, applications, and rigid pipes. It can solve the problems of poor assembly concentricity between the oil pipeline and the insulation layer, and uneven thickness of the insulation layer, so as to achieve good insulation effect, good concentricity, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

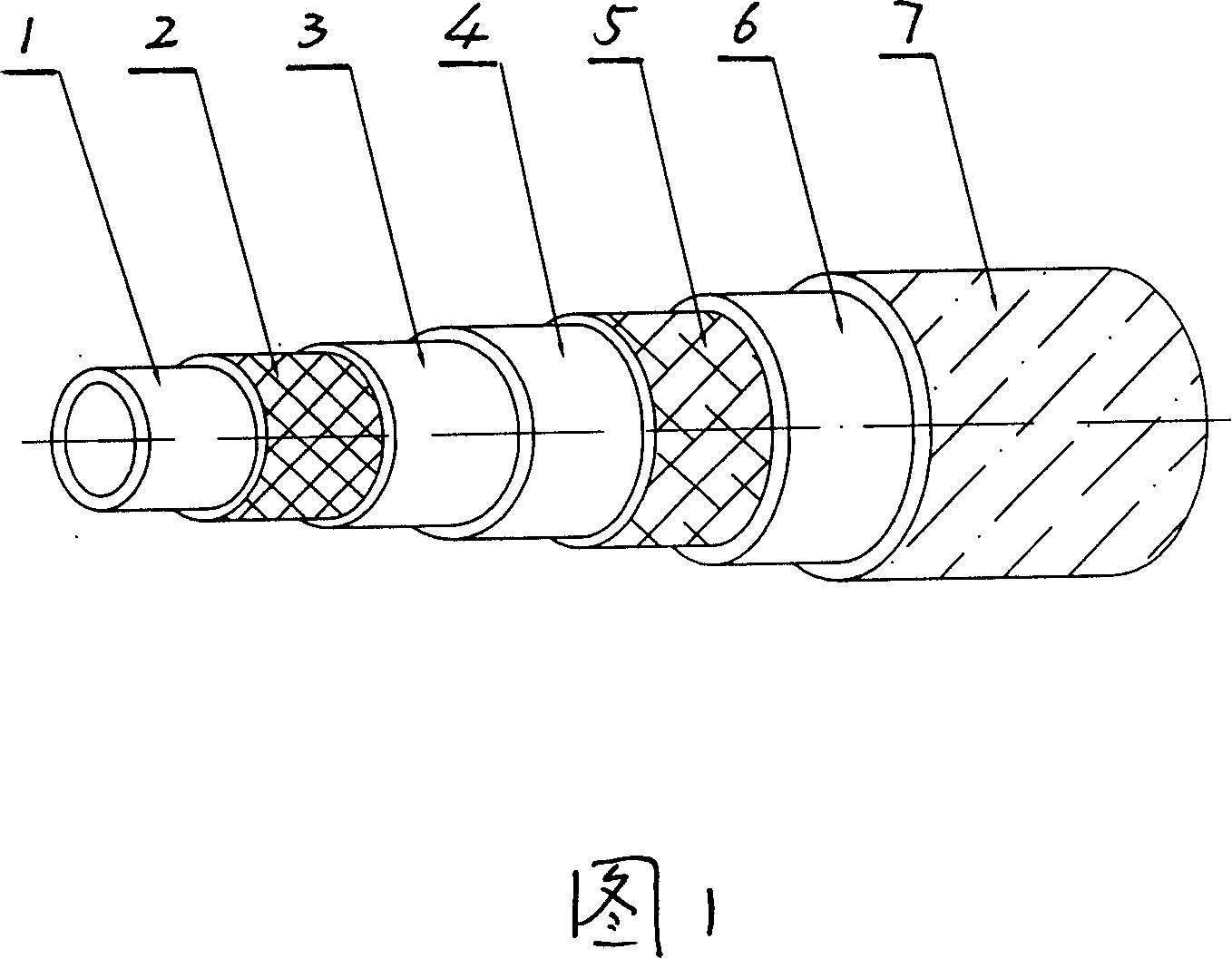

[0019] The structure of the continuous reinforced plastic thermal insulation composite pipeline for buried oilfield is shown in Figure 1. The composite pipeline body consists of anticorrosion layer 1, reinforcement layer 2, cladding layer 3, sealant layer 4, insulation layer 5, sealant layer 6, protection layer Layer 7, the continuous reinforced plastic composite pipe is formed by the anticorrosion layer 1, the reinforced layer 2, and the cladding layer 3, and the cross-linked polyethylene foam material is continuously wrapped on the continuous reinforced plastic composite pipe to form a continuous insulation layer 5. A sealant layer 4 and 6 are respectively coated between the layer 3 and the insulation layer 5 and between the insulation layer 5 and the protective layer 7 .

[0020] The reinforcing layer is braided by metal steel wires, the material of the anti-corrosion layer and the cladding layer is cross-linked polyethylene, the material of the protective layer and the seal...

Embodiment 2

[0022] Pass 98 parts by weight of polyethylene cross-linking grafts, 5 parts by weight of polyethylene catalyst masterbatch and 2 parts of polyethylene-based hot melt adhesive through the co-extrusion die, vacuum sizing and cooling to form an inner tube Anti-corrosion layer 1;

[0023] co-extrusion process

[0024] Barrel process: Zone 1: 60~80℃, Zone 2: 150~160℃, Zone 3: 160~170℃,

[0025] Zone 4: 160~170℃, Zone 5: 165~170℃;

[0026] Die head process: Sixth zone: 165~170℃, Seventh zone: 150~160℃, Eighth zone: 150~60℃;

[0027] Host speed: 40-70 rpm, traction speed: 2-3 m / min, vacuum degree: 0.02-0.03MPa;

[0028] On the anticorrosion layer 1, one or more layers of steel wires are braided by a braiding machine to form the reinforcement layer 2, and the reinforcement layer 2 is covered with a polyethylene coating layer 3, and a thin layer of sealing layer is evenly coated on the coating layer 3. Adhesive layer 4, wrap the cross-linked polyethylene foam insulation layer 5 lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com