Continuous die for manufacturing vehicle connecting plate and continuous manufacture method of vehicle connecting plate

A vehicle connection and mold technology, which is applied in the field of machinery, can solve problems such as troublesome operation, manpower, complex equipment, and high equipment cost, and achieve the effects of small production errors, improved production quality, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

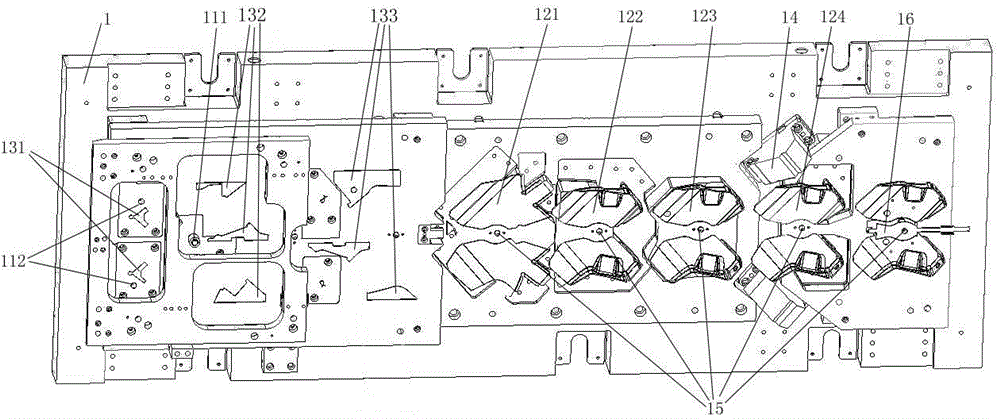

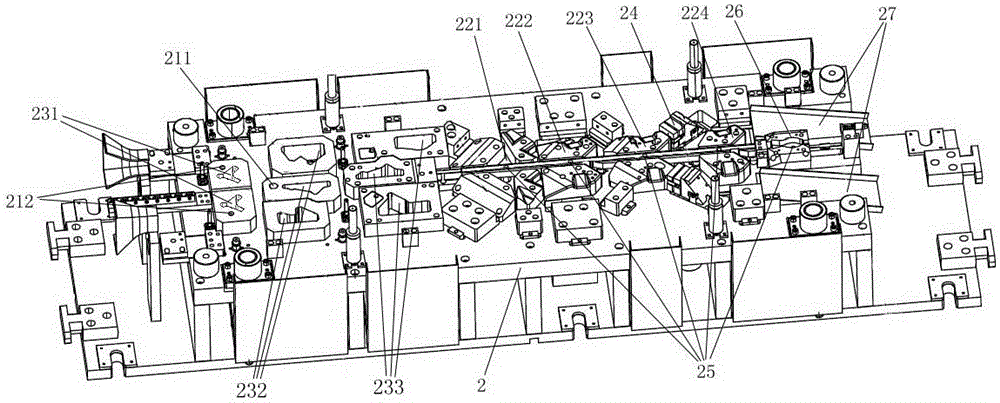

[0044] like Figure 1-6 As shown, the continuous mold for manufacturing the vehicle connecting plate provided in this embodiment includes an upper mold 1 and a lower mold 2, and the upper mold 1 and the lower mold 2 are respectively provided with corresponding guide columns and guide platforms;

[0045] The upper die 1 is provided with a punch group, a forming punch group, a trimming knife group, a side punching bevel 14 and a cutting knife 16;

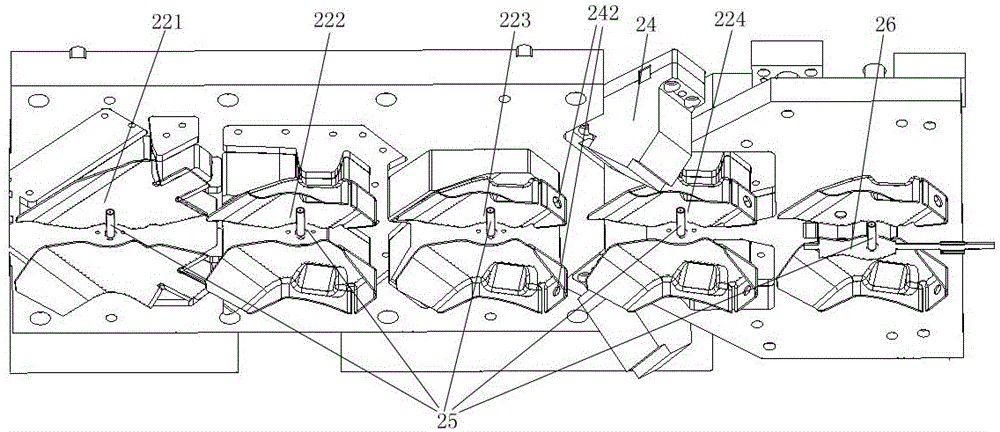

[0046] The lower die 2 is correspondingly provided with a punch die set, a forming die set, a trimming die set, a side punching slider 24 and a cutting groove 26 correspondingly to the upper die 1;

[0047] The side punching angle 14 is arranged behind the forming convex die set, and is fixedly installed on the upper mold 1, and its lower end surface is an inclined plane; the side punching slider 24 is arranged on the lower mold 2 through a slide rail 241 , the end of the slide rail 241 is provided with a side punching fixed die 223,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com