LED bulb surface detection device and method

A technology for LED light bulbs, surface detection, applied in the direction of detecting the appearance of fluid at the leak point, testing optical properties, using liquid/vacuum degree for liquid tightness measurement, etc. To achieve the effect of saving manpower, avoiding position deviation, and avoiding failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

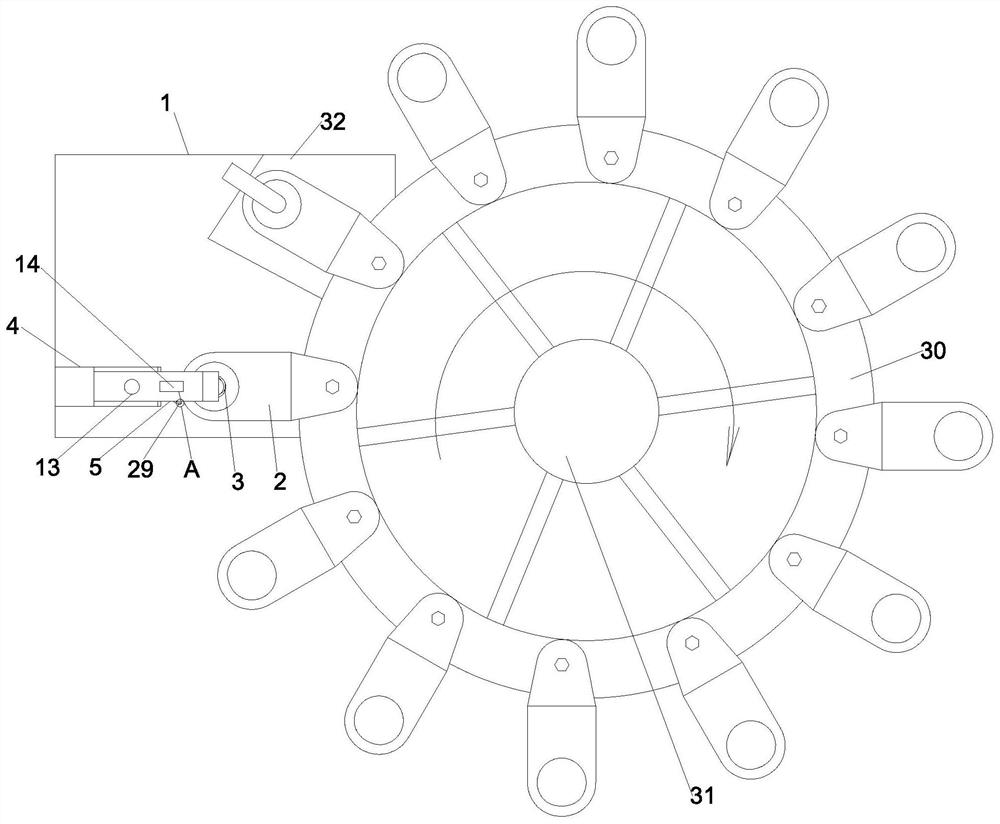

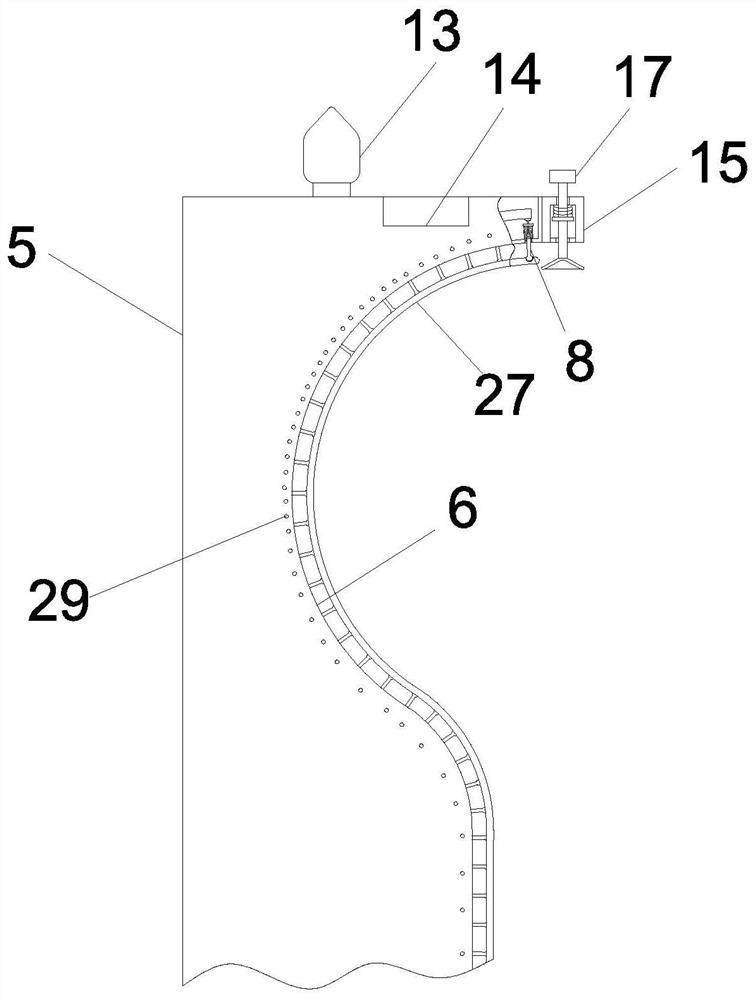

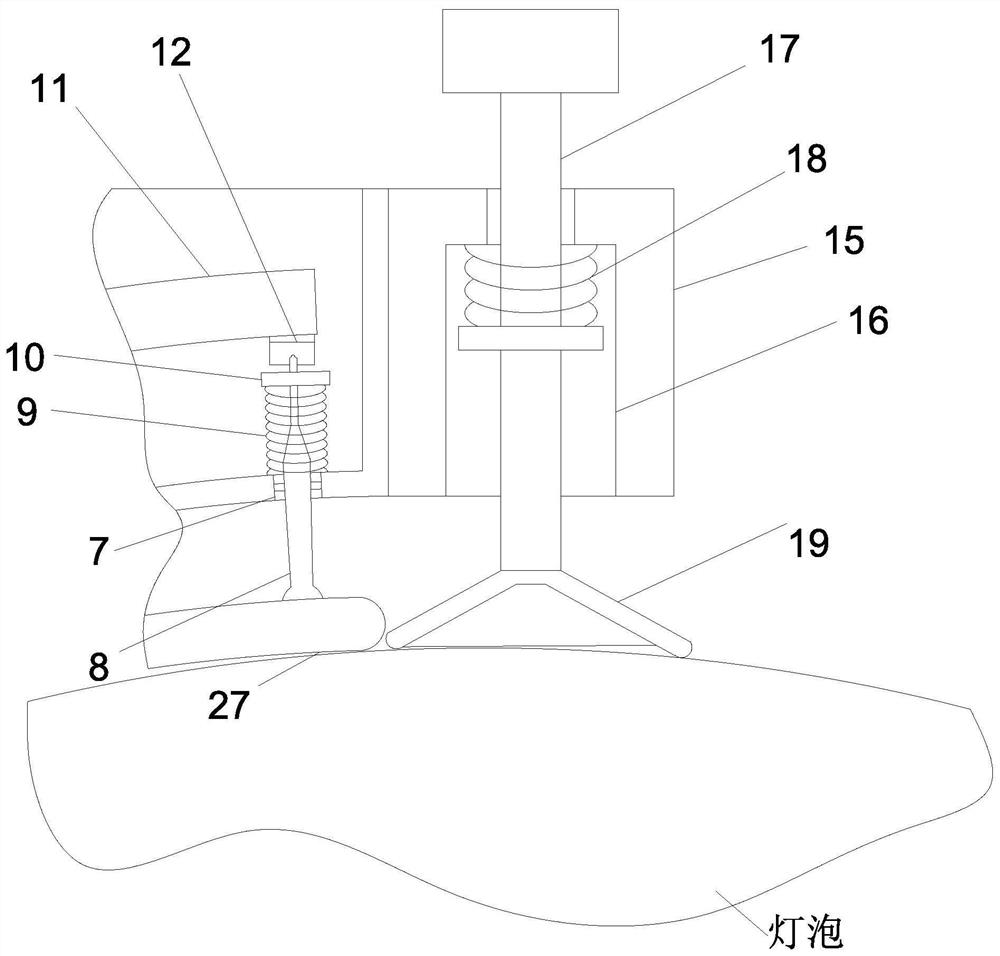

[0037] see Figure 1-8 , the present invention provides a technical solution: a device for detecting the surface of an LED light bulb, including a workbench 1, on which a turning block 2 is rotatably installed, on which a light bulb screw seat 3 is rotatably installed, on the workbench 1 A chute 4 is opened, and a mounting block 5 is slidably installed in the chute 4. An opening 6 is provided on the mounting block 5, and a scraping device is installed in the opening 6. A display component is mounted on the mounting block 5. The shape of the opening 6 is consistent with the The surface of the bulb to be tested is consistent, and the scraping device cooperates with the display component to realize the surface roughness detection of the bulb. The position of the scraping device can be adjusted by sliding the mounting block 5. When the mounting block 5 moves to the rightmost end of the chute 4 , at this moment, the scraping device is in close contact with the surface of the bulb scr...

Embodiment 2

[0045] A device for detecting the surface of an LED light bulb, comprising a workbench 1, the bottom end of the workbench 1 is supported by a support leg 37, and one side of the top of the workbench 1 is provided with an intermittent rotating shaft 31, and the intermittent rotating shaft 31 is in the center of the workbench 1. One side rotates intermittently, and the top of the intermittent rotating shaft 31 is fixedly equipped with a swivel 30 of circular structure, and the top of the swivel 30 is fixedly installed with several turning blocks 2 at equal intervals, and each turning block 2 is rotatably installed with a bulb screw connection seat 3. A plurality of LED bulbs are rotatably installed on the bulb screw seat 3 of each turn block 2. A chute 4 is provided on the workbench 1. A mounting block 5 is slidably installed in the chute 4, and an opening is opened on the mounting block 5. 6, and a scraping device is installed in the opening 6, and a display component is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com