Installation structure of current sampling resistor

A technology of installation structure and current sampling, applied in the direction of resistor installation/support, resistance terminal/electrode, improvement of basic electrical components, etc. Sampling values and other issues to achieve the effect of avoiding differences, ensuring accuracy, and ensuring the accuracy of resistance values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

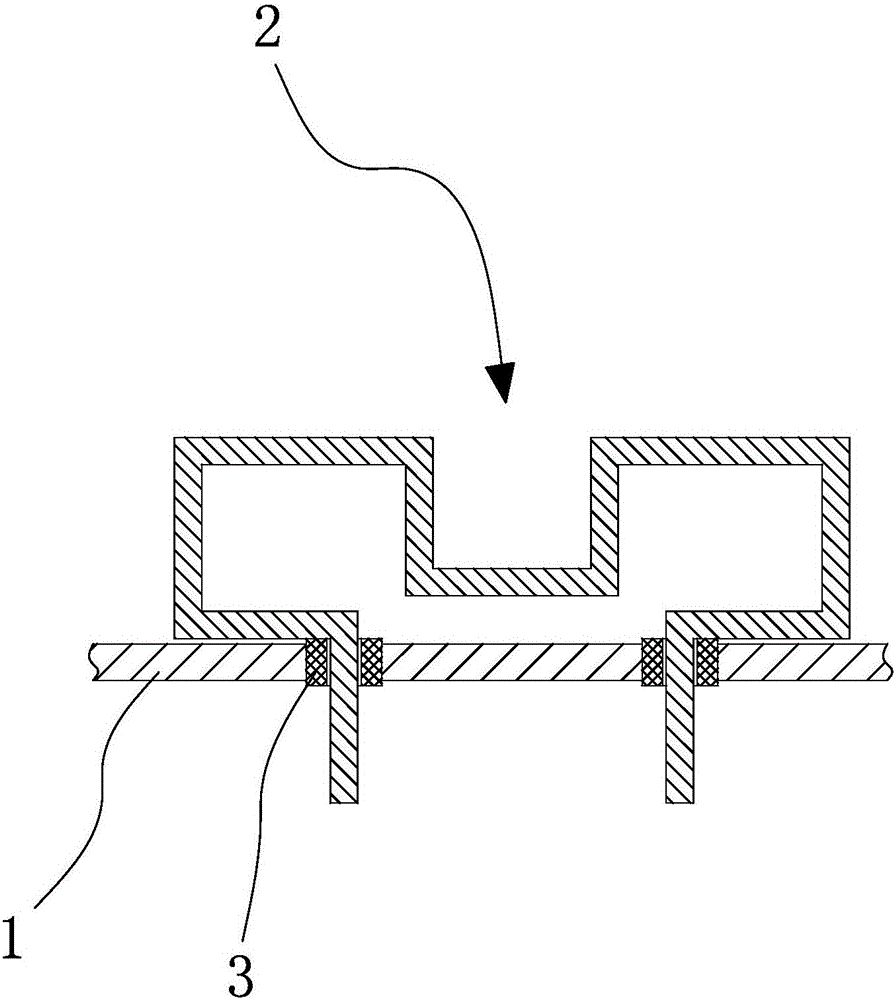

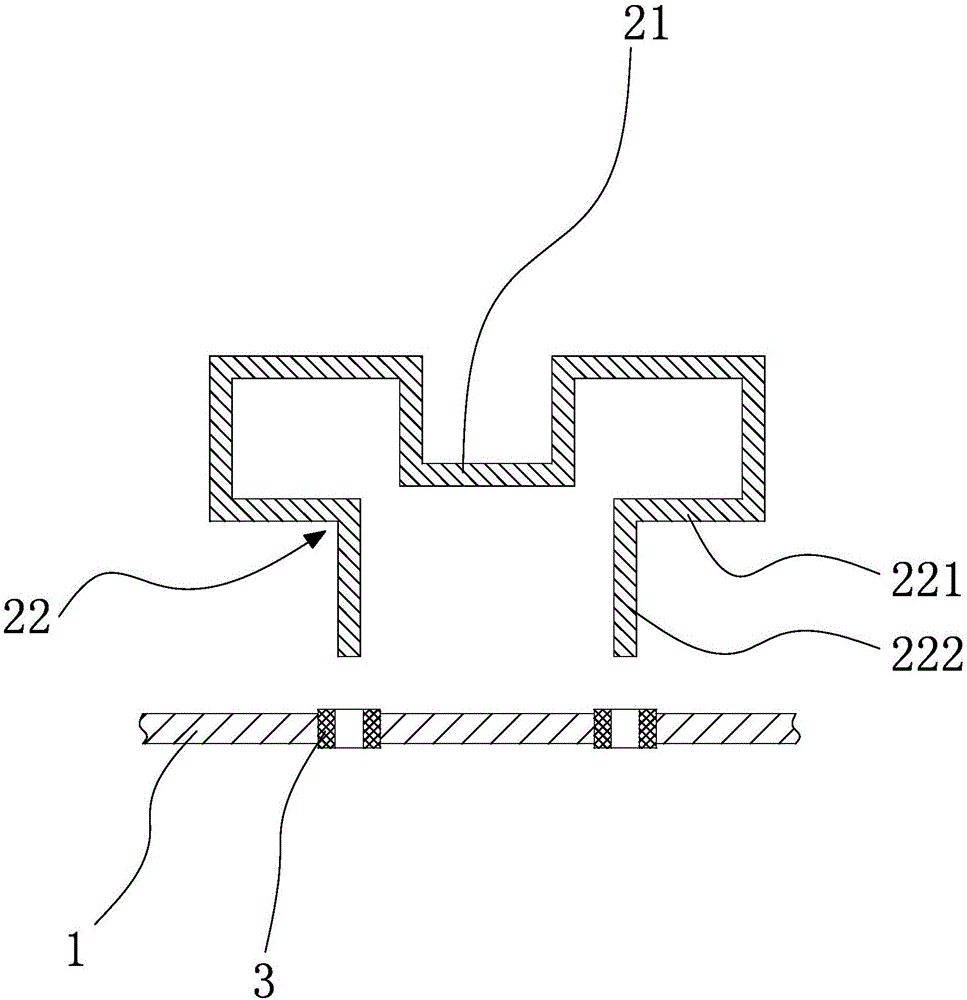

[0018] The first embodiment includes a PCB board 1 and a current adopting resistor 2 , and the current adopting resistor 2 is connected to the PCB board 1 through a pad 3 . The current adopting resistor 2 includes a sampling terminal 21 and two wires 22 arranged on both sides of the sampling terminal 21. The wires 22 include a first line segment 221 and a second line segment 222. One end of the first line segment 221 is connected to the sampling end 21, and the second line segment 221 is connected to the sampling end 21. The other end of the line segment 221 is connected to the second line segment 222, the setting direction of the first line segment 221 is parallel to the board surface of the PCB board 1, and the setting direction of the second line segment 222 is perpendicular to the board surface of the PCB board 1, respectively belonging to two The lengths of the two first line segments 221 of one wire 22 are equal, and the lengths of the two second line segments 222 belongi...

Embodiment 2

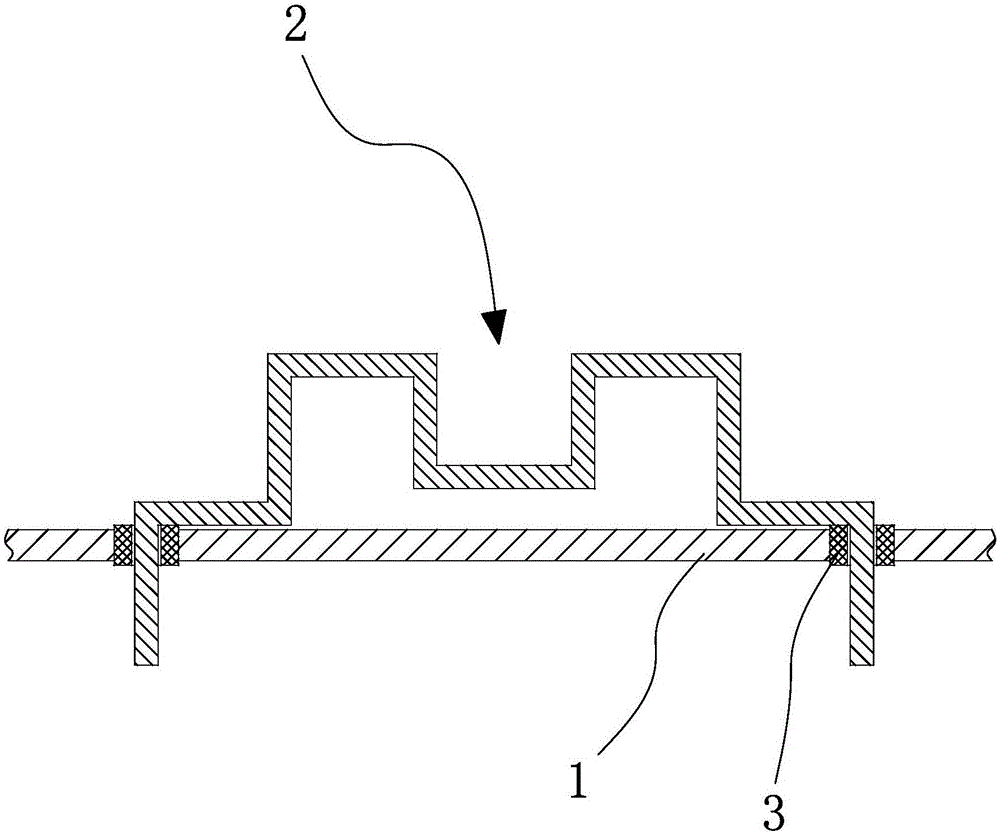

[0021] The structure of the second embodiment is basically the same as that of the first embodiment, the difference is that the second line segment 222 in the second embodiment is bent outward and downward from the first line segment 221 to be suitable for two via holes PCB boards with large spacing 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com