Multifunctional test bench for chip

A multi-functional test and test bench technology, applied in short-circuit test, electronic circuit test, measurement of electricity, etc., can solve the problems of chip false test, insufficient pressure, test head jitter, etc., to prevent false test and prevent insufficient pressure. , the effect of reducing downward pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

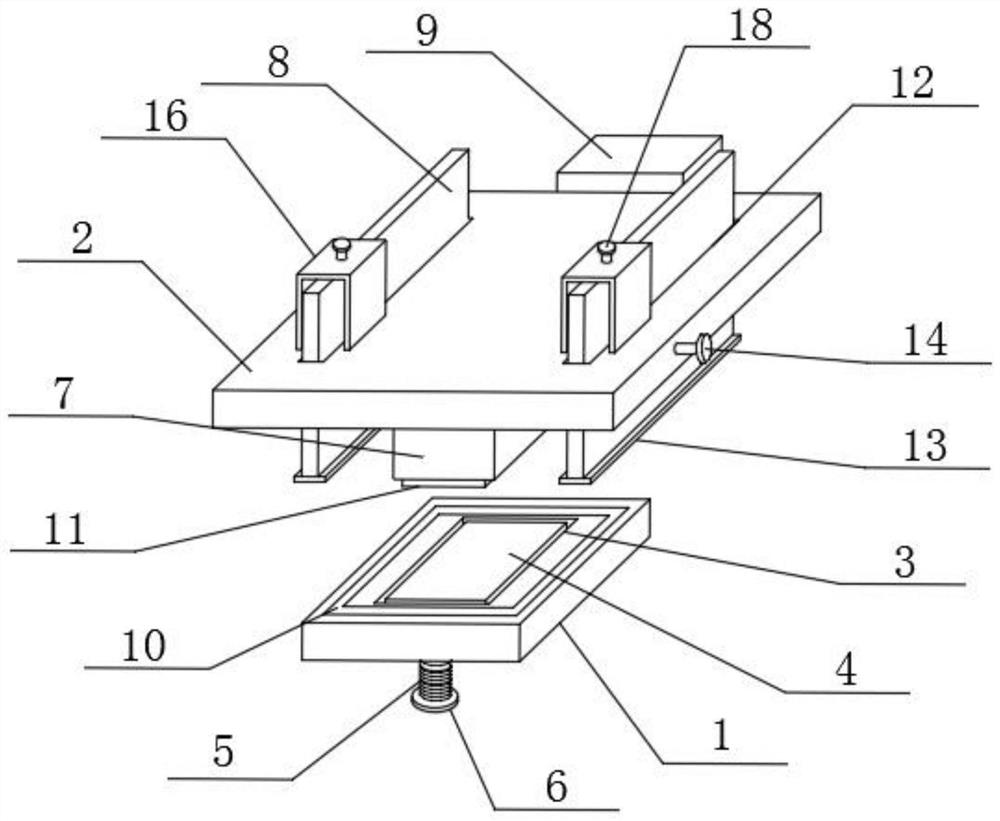

[0024]Such asfigure 1 withimage 3 As shown, a multifunctional chip test bench includes a test bench 1 and a pressing plate 2. A groove 3 is opened in the middle of the top surface of the test bench 1, and a detection board 4 is provided in the groove 3. An inserting rod 5 is provided in the middle of the bottom surface, a connecting ring 6 is provided at the bottom of the inserting rod 5, a connecting block 7 is installed in the middle of the bottom surface of the extrusion plate 2, and the interior of the extrusion plate 2 is set at a limited position near both sides The position plate 8 has a detector 9 mounted on the rear surface of the pressing plate 2.

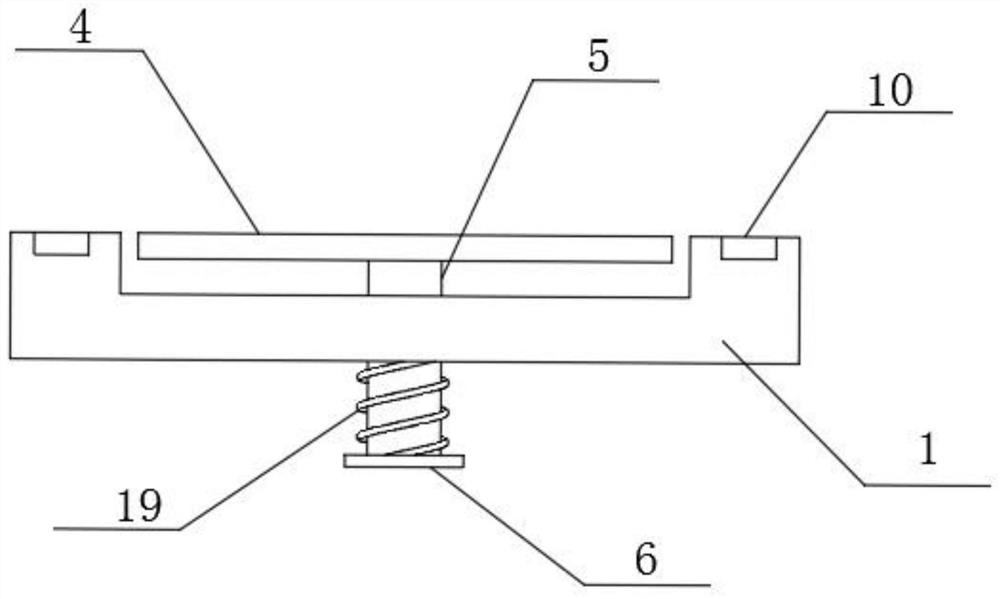

[0025]The test bench 1 is in the shape of a rectangular parallelepiped. The test bench 1 is provided with a detection board 4 in the middle of the upper surface of the test bench 1, and the groove 3 encloses the detection board 4 in it. The groove 3 is rectangular. On the bottom surface, a washer 10 is embedded in the upper surfac...

Embodiment 2

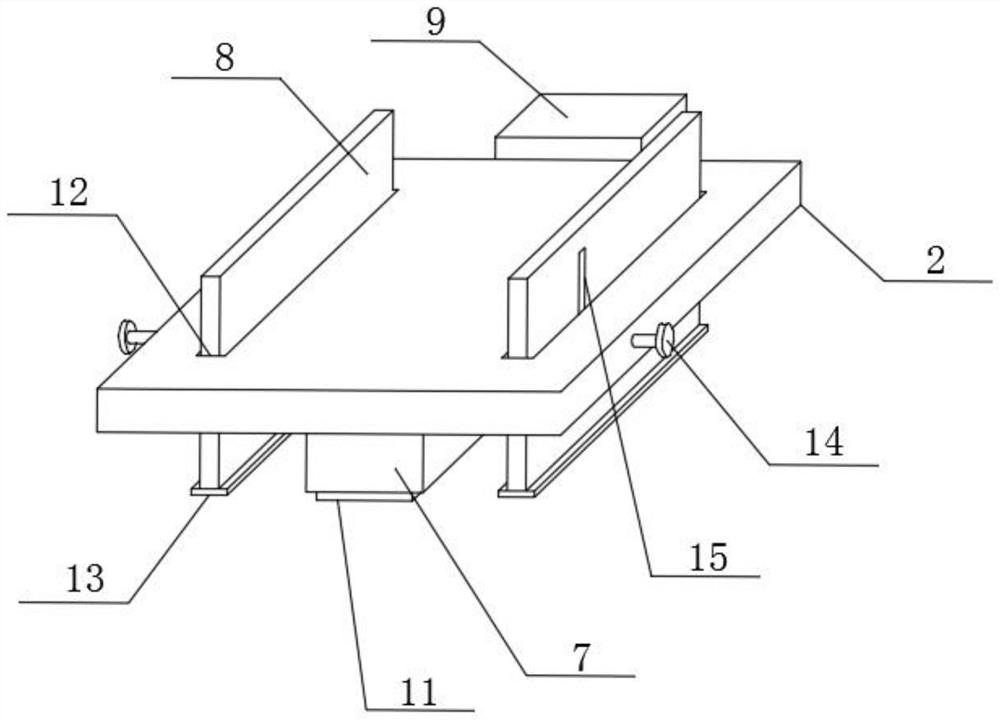

[0027]On the basis of Example 1, such asfigure 2 withFigure 4As shown, both sides of the test bench 1 are provided with grooves 3 for accommodating the limit plates, which can facilitate the relative sliding of the limit plates 8 inside the test bench 1, and the two sides of the connecting block 7 are provided with notches 12. 12 is a long rectangle, the number of notches 12 is two, the limit plate 8 passes through the notch 12, there are two limit plates 8, and the bottom end of the limit plate 8 is equipped with a contact plate 13, the contact plate There are two 13 in number. When the pressing plate goes down, the contact plate will touch the washer, which can prevent the chip from being fractured. Both sides of the pressing plate 2 are provided with adjusting bolts 14 which pass through the screw holes. 17 passes through the side of the extrusion plate 2 and the slot and is screwed to each other with the limit plate 8. The inner surface of the limit plate 8 on the right side is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com