Glass bottle manufacturing device and application method thereof

A technology for manufacturing devices and glass bottles, which is applied in glass manufacturing equipment, glass blowing, glass molding, etc. It can solve problems such as burrs, unevenness, and time-consuming, and achieve uniform molding, improve processing efficiency, and save processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further detailed explanation through specific implementation mode below:

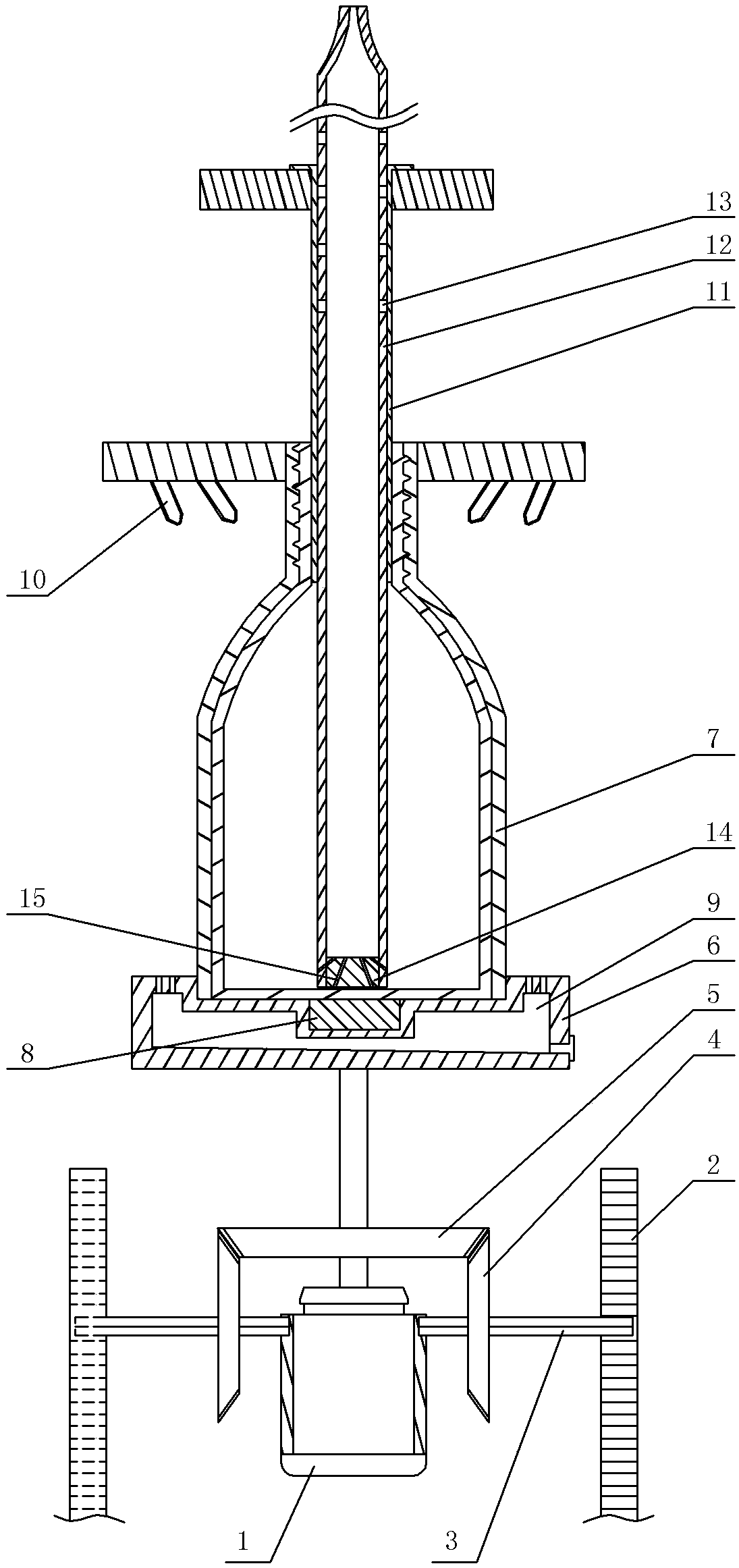

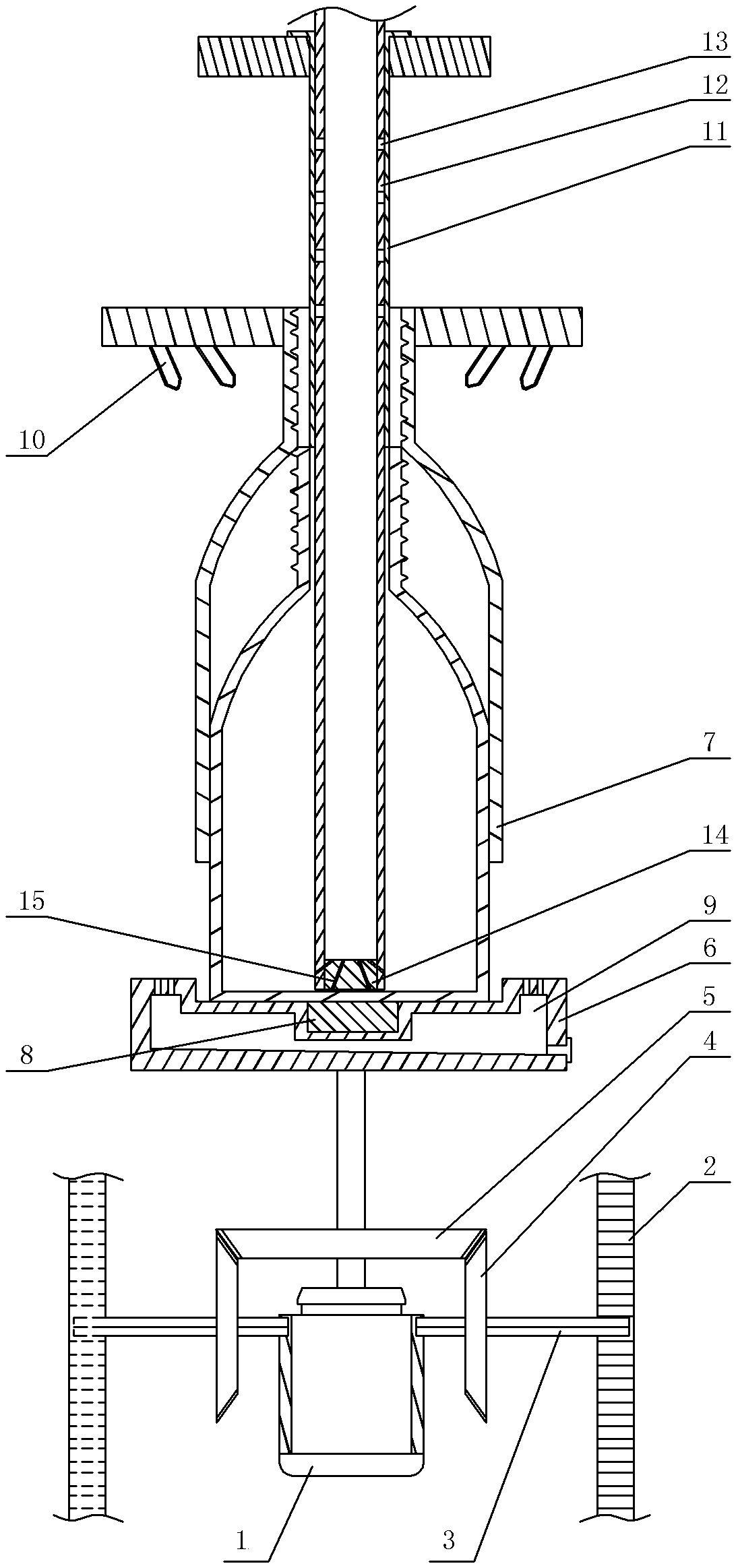

[0025] The reference signs in the accompanying drawings of the description include: servo motor 1, rack 2, gear bar 3, first bevel gear 4, second bevel gear 5, support plate 6, bottle body mold 7, first magnet 8, water collecting Cavity 9, spray pipe 10, outer casing 11, inner casing 12, hole 13, second magnet 14, air outlet 15.

[0026] Such as figure 1 , 2 The shown glass bottle making device includes a screwing mechanism and a molding blowing mechanism. The screwing mechanism includes a servo motor 1 and two left and right screwing units, each screwing unit includes a rack 2 and a rack 3, the rack 2 is vertically fixed on the frame, and the rack 3 is rotatably arranged on the side of the servo motor 1 On the casing, the gear bar 3 meshes with the rack 2, and the first bevel gear 4 is coaxially fixed on the gear bar 3. A second bevel gear 5 is coaxially fixed on the output shaft of the serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com