Sediment separating system

A technology for sediment separation and sediment, which is applied in the direction of solid separation, wet separation, and separation of solids from solids with airflow, which can solve the problems of no sawdust removal and poor separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

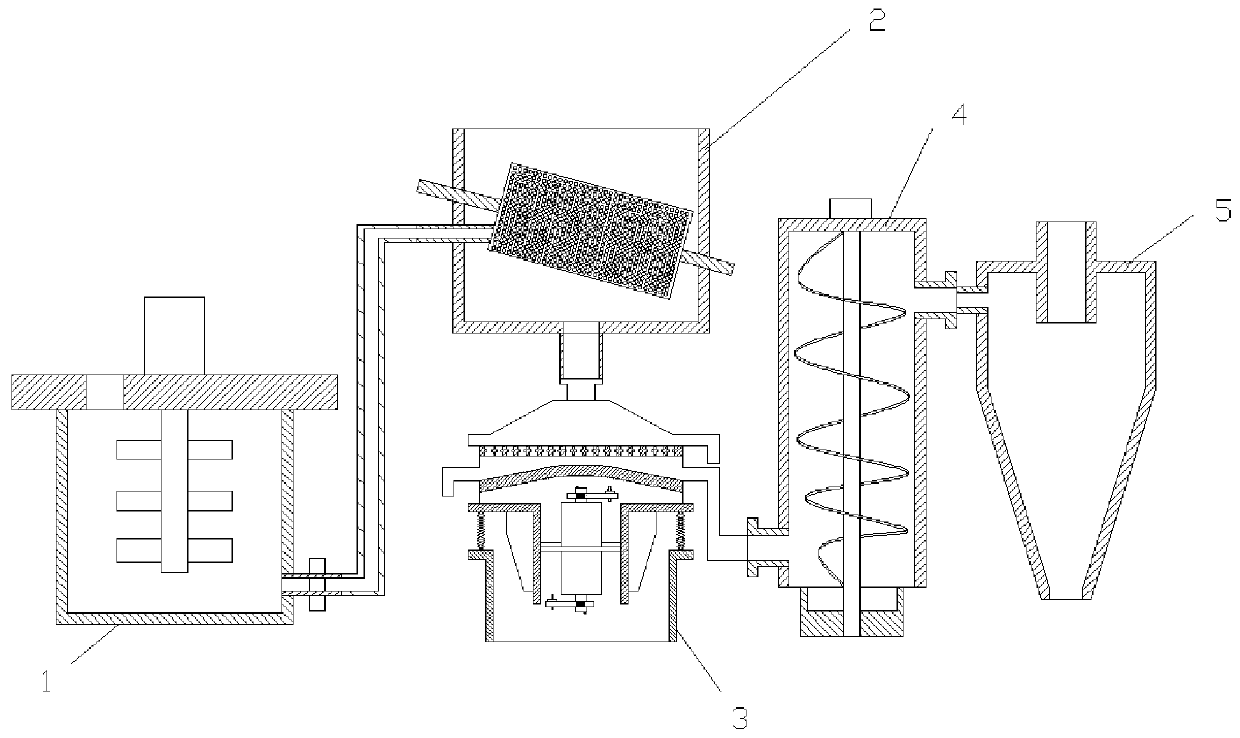

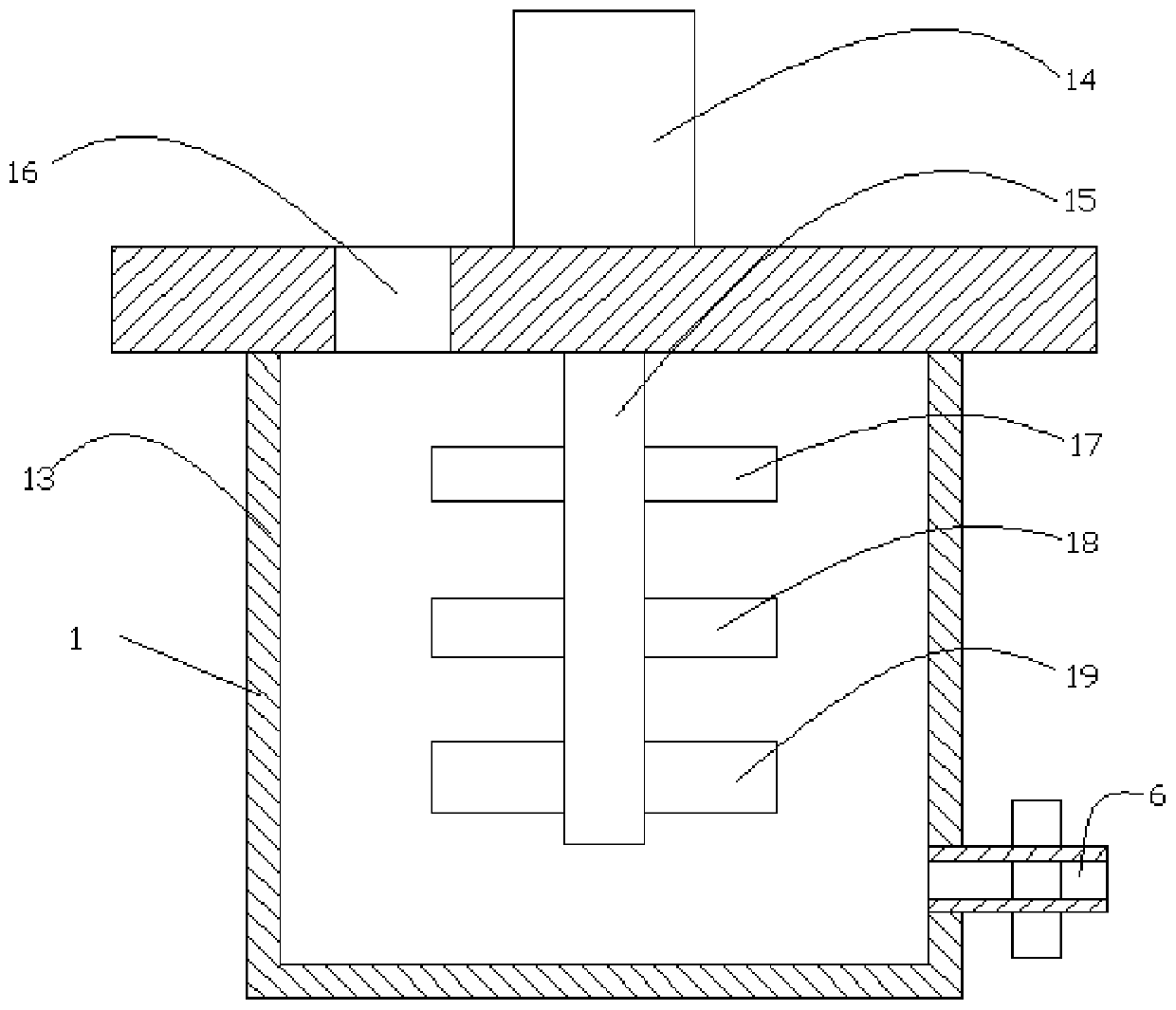

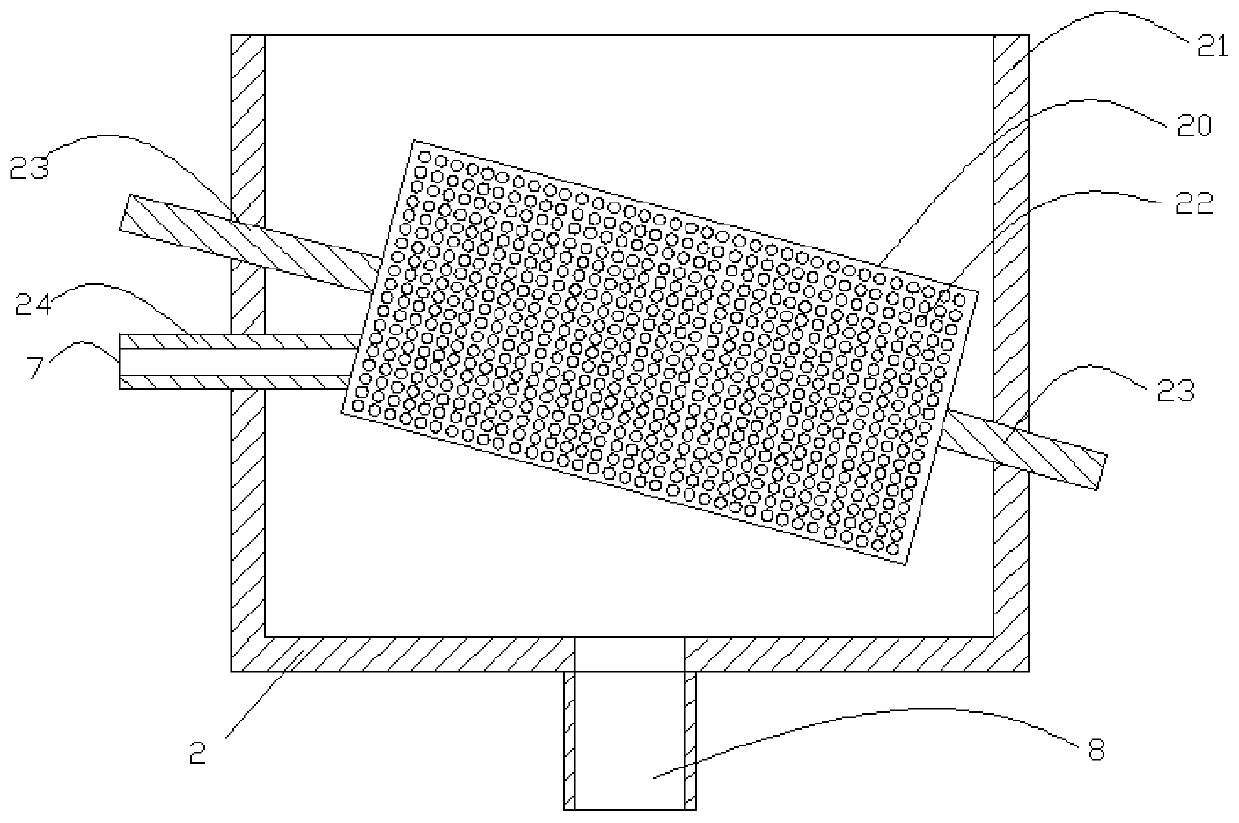

[0032] As shown in the figure, the present invention provides a silt separation system, which includes a silt removal sawdust device and a silt separation device, and the silt removal sawdust device includes a stirring tank 1 for dissolving the silt, The pig cage screen 2 for removing sawdust for the first time and the vibrating screen 3 for removing sawdust for the second time are used to remove the sawdust for the first time. Machine 4 and the cyclone 5 that silt is separated for the second time, the silt first enters the silt removal sawdust device and then enters the silt separation device. The advantage of the present invention is that the silt removal sawdust device and the silt removal device The separation device first uses the sediment removal sawdust device to remove sawdust from the sediment, and then uses the sediment separation dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com