Wireless cutter for power hot-line work

A technology of live operation and cutting knife, which is applied to overhead lines/cable equipment, etc., can solve the problem of inconvenient operation and the inconvenience of one person's hands when insulating the operating rod, and achieve the effect of realizing working space and wireless long-distance communication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

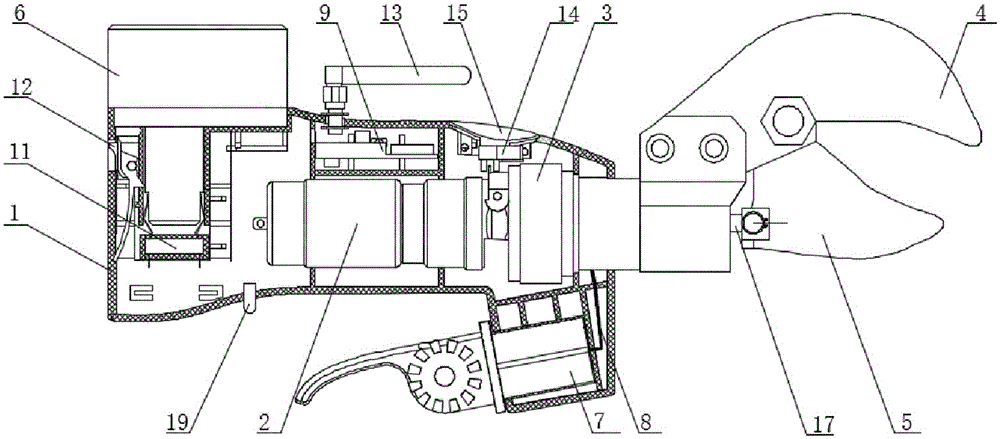

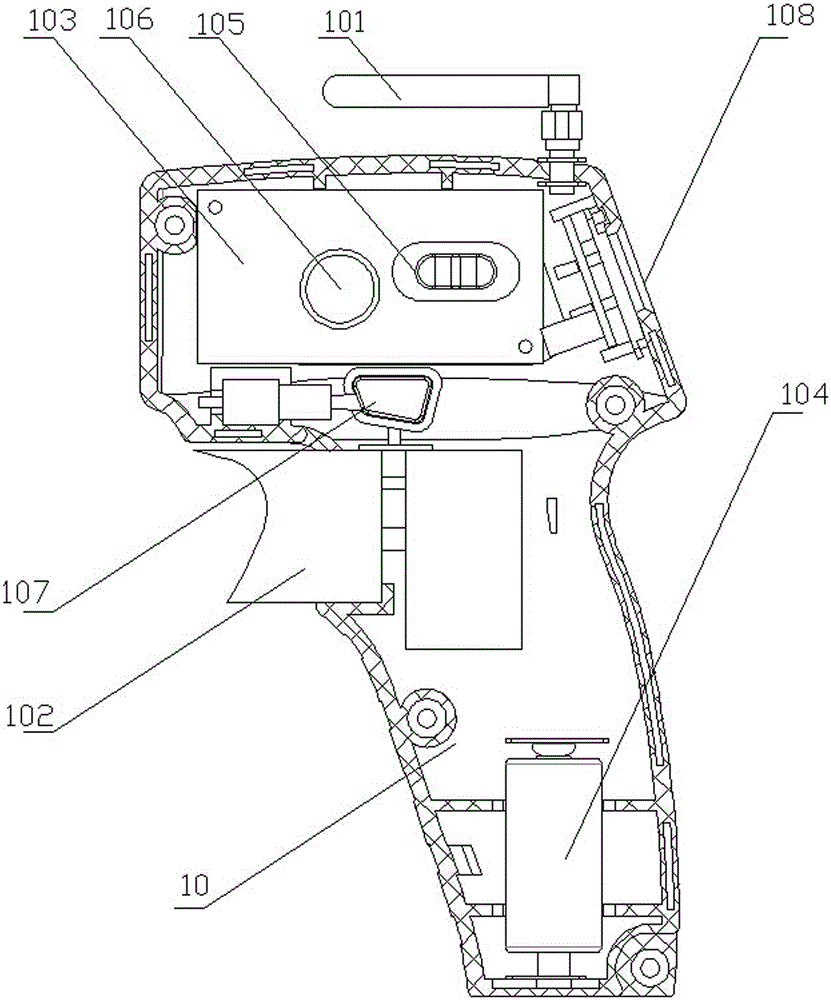

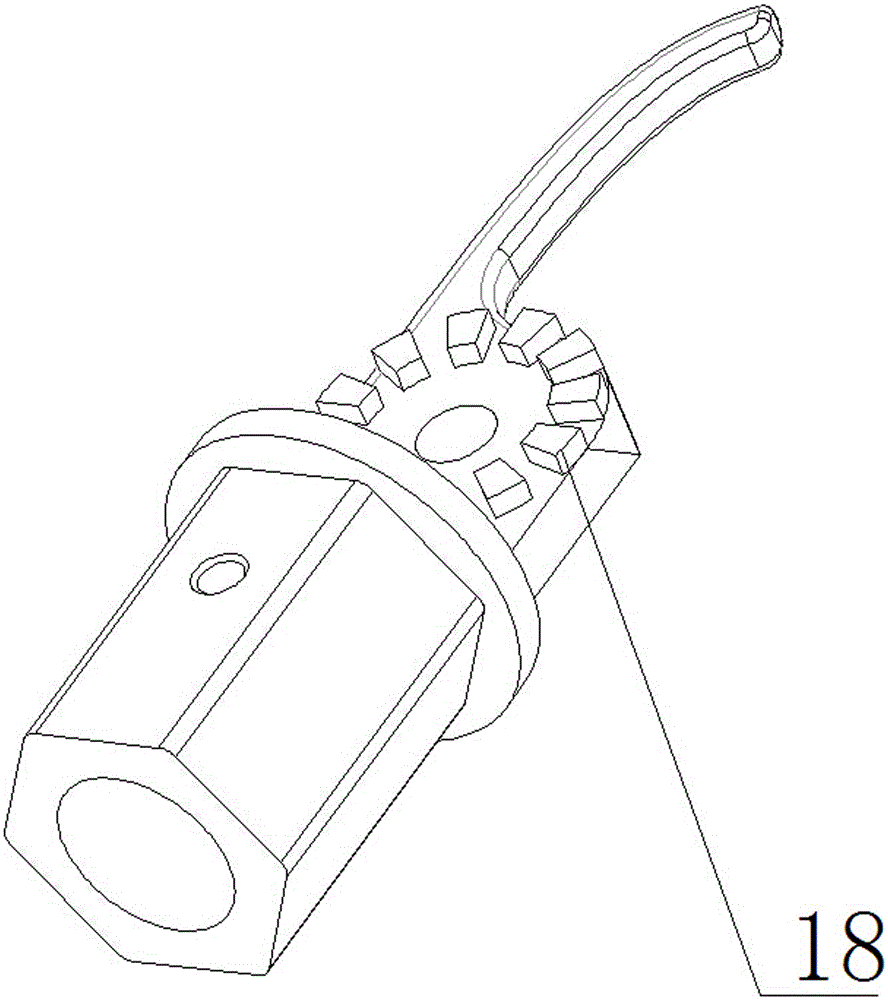

[0038] Such as Figure 1-4 As shown, the product of the present embodiment comprises a cutter housing 1, a drive motor 2, a pump body 3, a fixed cutter 4 and a movable cutter 5, and the pump body 3 is controlled by the drive motor 2 to push the movable cutter 5 forward, so that the movable The cutter 5 and the fixed cutter 4 complete the cutting action. This embodiment also includes a cutter battery 6, a connecting sleeve 7, a grounding wire 8, a control circuit 9 and a wireless remote controller 10. The control circuit 9 includes a motor drive circuit and a wireless remote control communication circuit; the control circuit 9 communicates data with the wireless remote controller 10 by driving the wireless remote control communication circuit; the motor drive circuit controls the operation of the drive motor 2; the control circuit 9 is powered by the cutter battery 6, and the control circuit 9 and the connecting sleeve 7 are connected through a ground wire 8 connections; this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com