Preparation method of solid state lithium battery composite cathode film

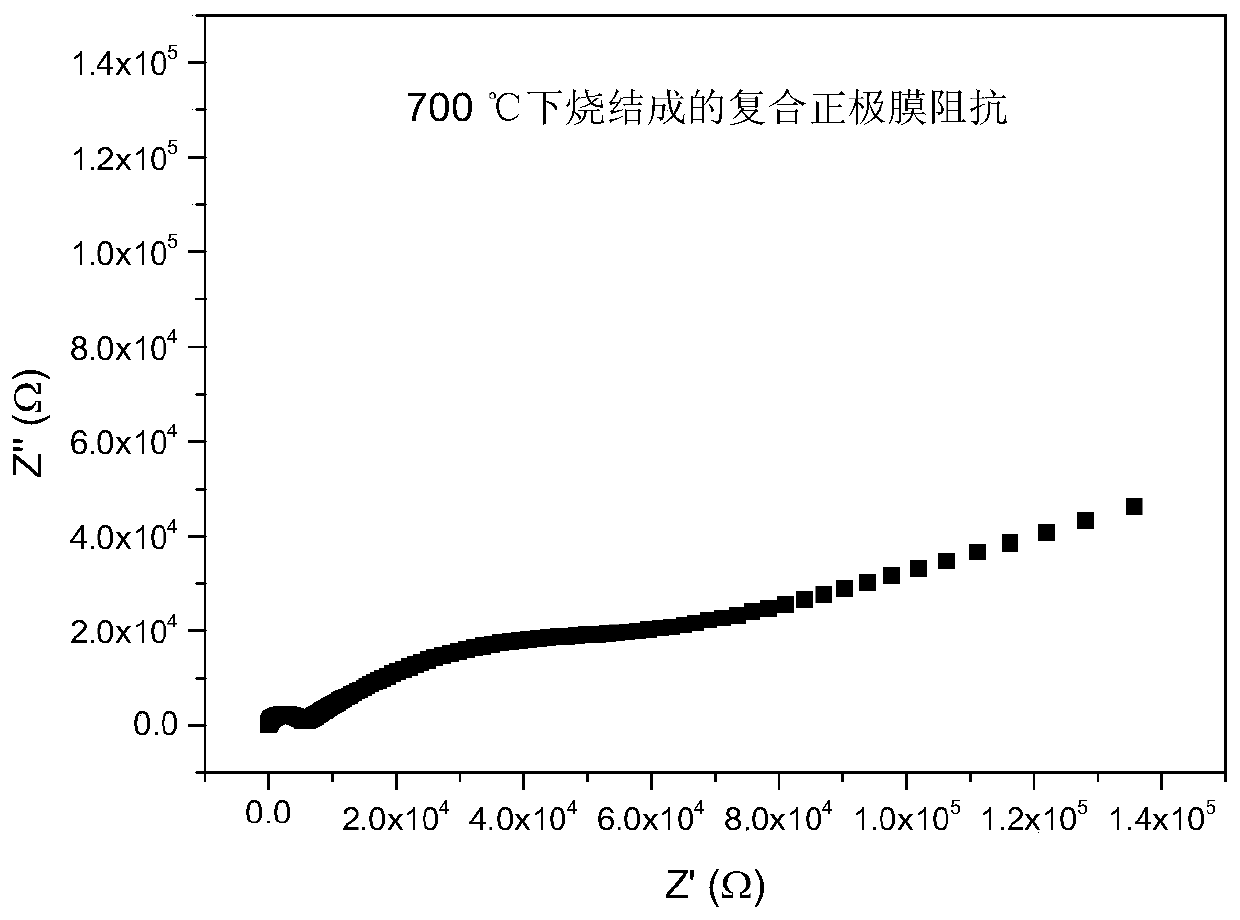

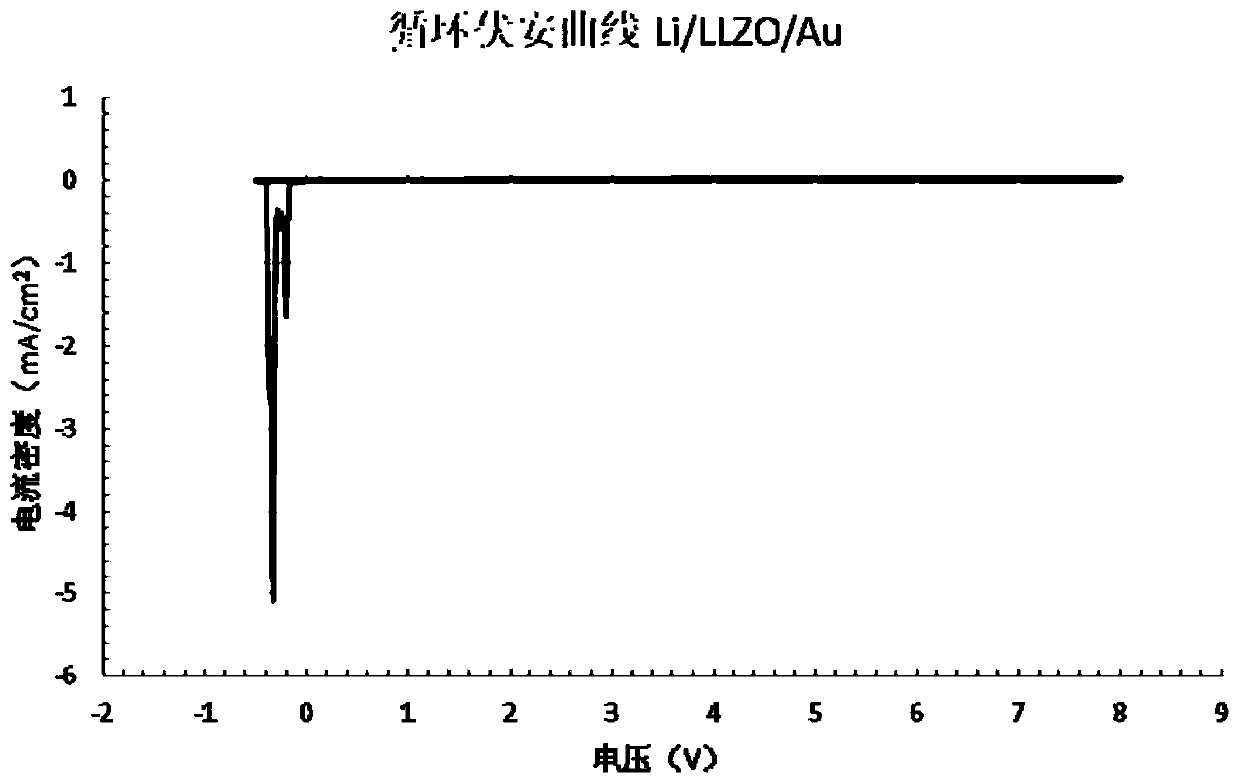

A composite cathode, solid lithium technology, applied in electrode manufacturing, battery electrodes, lithium batteries, etc., can solve problems such as the diffusion of sintered elements, reduce internal resistance, and increase the pores of the cathode film, and reduce the interface charge transfer resistance. The effect of improving interface densification and reducing interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

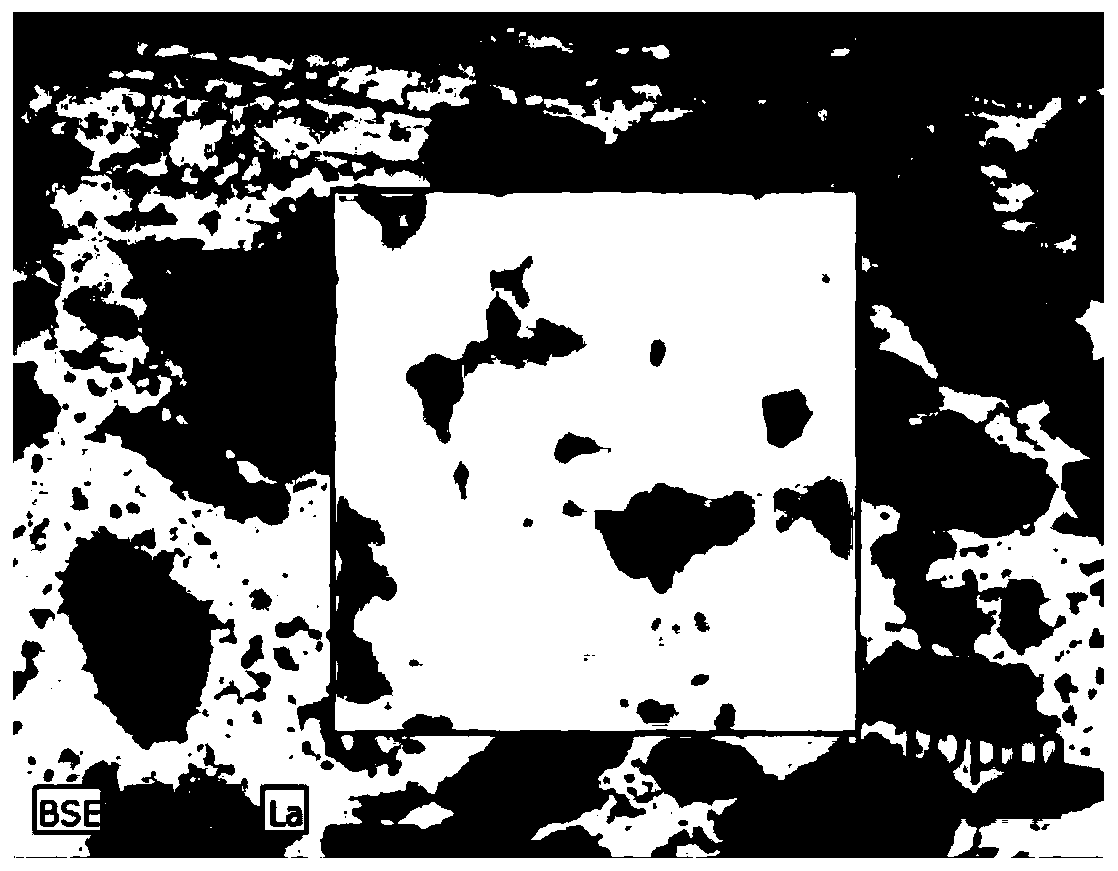

[0029] The active positive electrode particles nickel cobalt lithium manganate and LLZO solid electrolyte particles are mixed in proportion to form composite positive electrode powder particles, so that the particle diameters of the active positive electrode particles and LLZO solid electrolyte particles are both 100nm to 50μm, wherein the composite positive electrode powder particles The mass ratio of active positive electrode particles to LLZO solid electrolyte particles is 4:1, which is equivalent to 80wt% of positive electrode particles and 20wt% of LLZO solid electrolyte particles. A small amount of absolute ethanol, deionized Water or ethylene glycol, etc. The addition of the solvent here is mainly for the wetting effect and to improve the uniformity of the ball mill. Of course, it is also possible to mix the above raw materials without adding a solvent. The ball milling time is 5min~24h, and the ball milling temperature is 10 °C to 50 °C, after the ball milling is comple...

Embodiment 2

[0035] Mix the active positive electrode particles lithium cobaltate and LLZO solid electrolyte particles in proportion to form composite positive electrode powder particles, so that the particle diameters of the active positive electrode particles and LLZO solid electrolyte particles are both 200nm to 250nm, and the LLZO solid electrolyte particles are garnet-structured A ceramic material, wherein the mass ratio of the active positive electrode particles to the LLZO solid electrolyte particles in the composite positive electrode powder particles is 6.5:3.5, which is equivalent to 65 wt% of the positive electrode particles and 35 wt% of the LLZO solid electrolyte particles, A small amount of absolute ethanol, deionized water or ethylene glycol can be added, and the above-mentioned raw materials are mixed evenly by ball milling. The ball milling time is 1.0h, and the ball milling temperature is 25°C-30°C. After the ball milling is completed, the mixture is dried to obtain Compos...

Embodiment 3

[0041] The active positive electrode particles spinel lithium nickel manganese oxide and Ta-doped LLZO solid electrolyte particles are mixed in proportion to form composite positive electrode powder particles. The LLZO solid electrolyte particles are ceramic materials with a garnet structure. The Ta element in each mole of LLZO solid electrolyte The number of moles incorporated is 0.02 to 0.8, so that the particle diameters of the active positive electrode particles and the Ta-doped LLZO solid electrolyte particles are both 150nm to 200nm, wherein the active positive electrode particles in the composite positive electrode powder particles and the Ta-doped LLZO solid electrolyte particles The mass ratio of particles is 7:3, which is equivalent to 70wt% of positive electrode particles and 30wt% of LLZO solid electrolyte particles. A small amount of absolute ethanol, deionized water or ethylene glycol can be added to The above raw materials are mixed evenly by ball milling, the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com