Manufacturing method of semiconductor component

A component manufacturing and semiconductor technology, which is applied in the field of semiconductor component manufacturing, can solve problems such as difficult removal of the surface of the substrate and gate structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

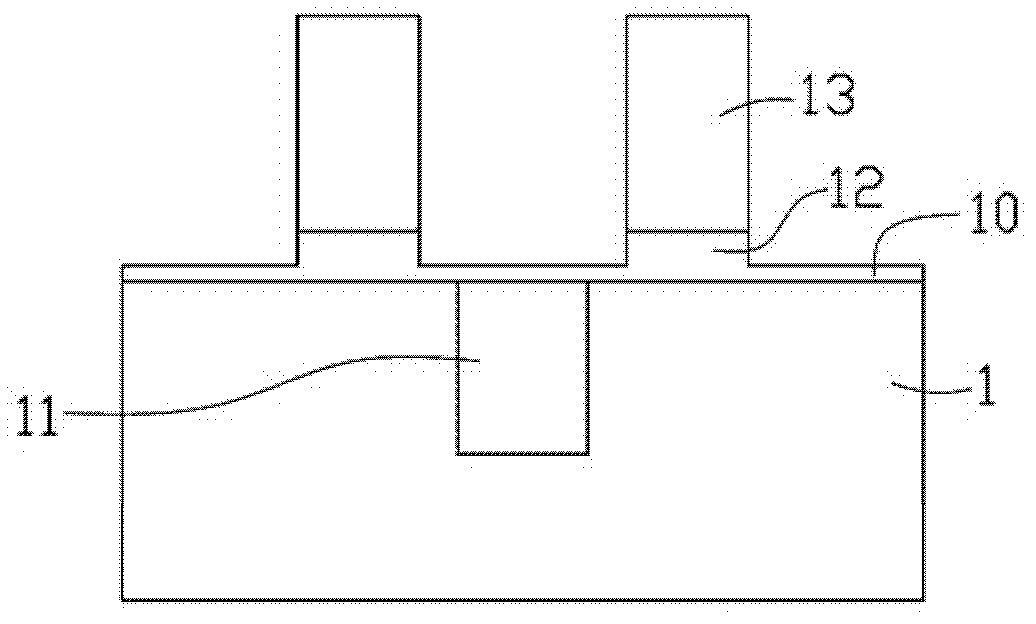

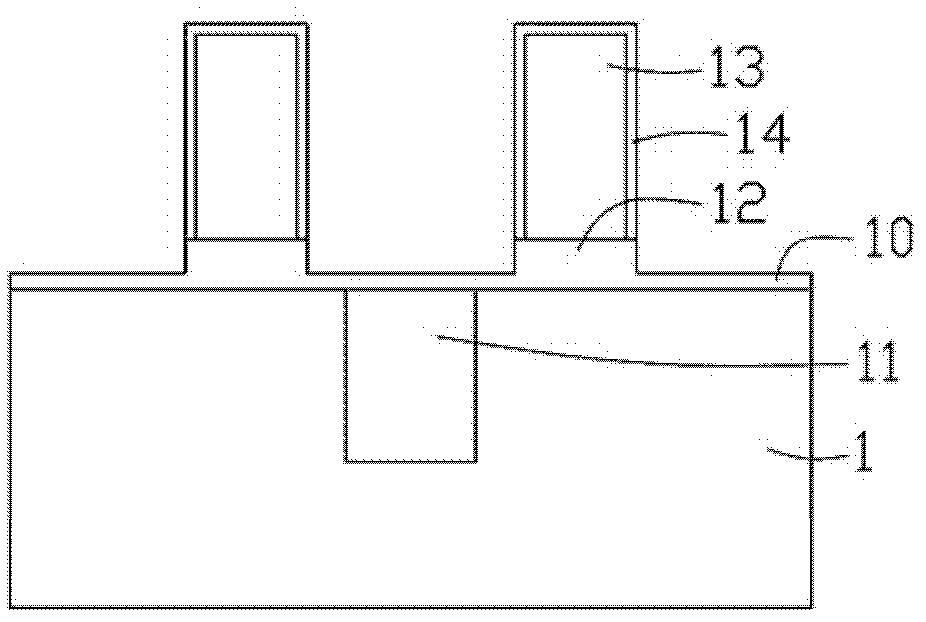

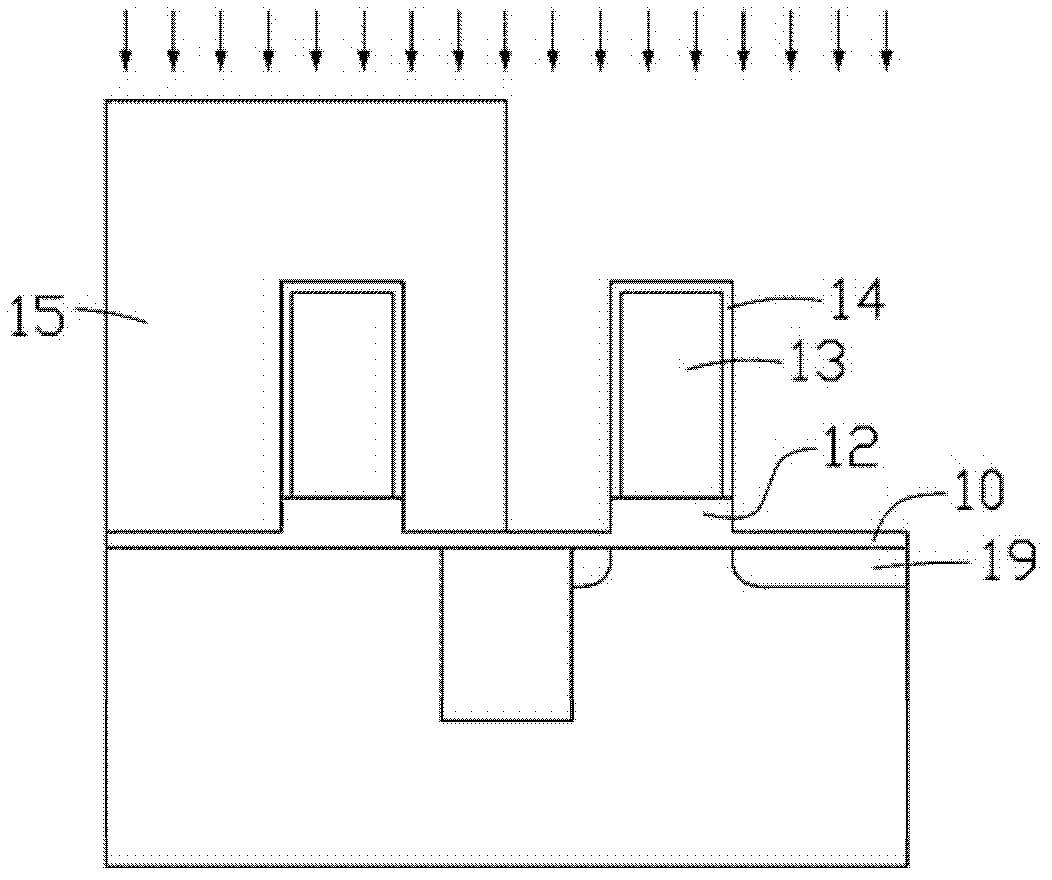

[0026] See Figure 1A ~ Figure 1F , which is a schematic flow diagram of part of the process of manufacturing a semiconductor element. first, Figure 1A It shows that after the shallow trench isolation structure 11 is completed on the silicon substrate 1 , the gate dielectric layer 12 and the silicon gate structure 13 are fabricated on the surface of the silicon substrate 1 . The silicon oxide layer 10 is silicon oxide remaining after the definition of the silicon gate structure 13 and the gate dielectric layer 12 is completed. In addition, the silicon gate structure 13 is a structure containing silicon, which may include uniform or gradient or heterogeneous Polycrystalline silicon, monocrystalline silicon, doped silicon, epitaxy of silicon and other elements or doped materials such as silicon germanium material, strained silicon, or any combination of the above. Also, although the silicon gate structure 13 shown in the figure is a single-layer structure, it can be a multi-la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com