Intercooler double-track welding device

A welding device and double-track technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of affecting the cooling efficiency of the engine, unsightly welding seams, and poor air tightness, so as to prevent the transfer of spatter and heat, The effect of high welding efficiency and high welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

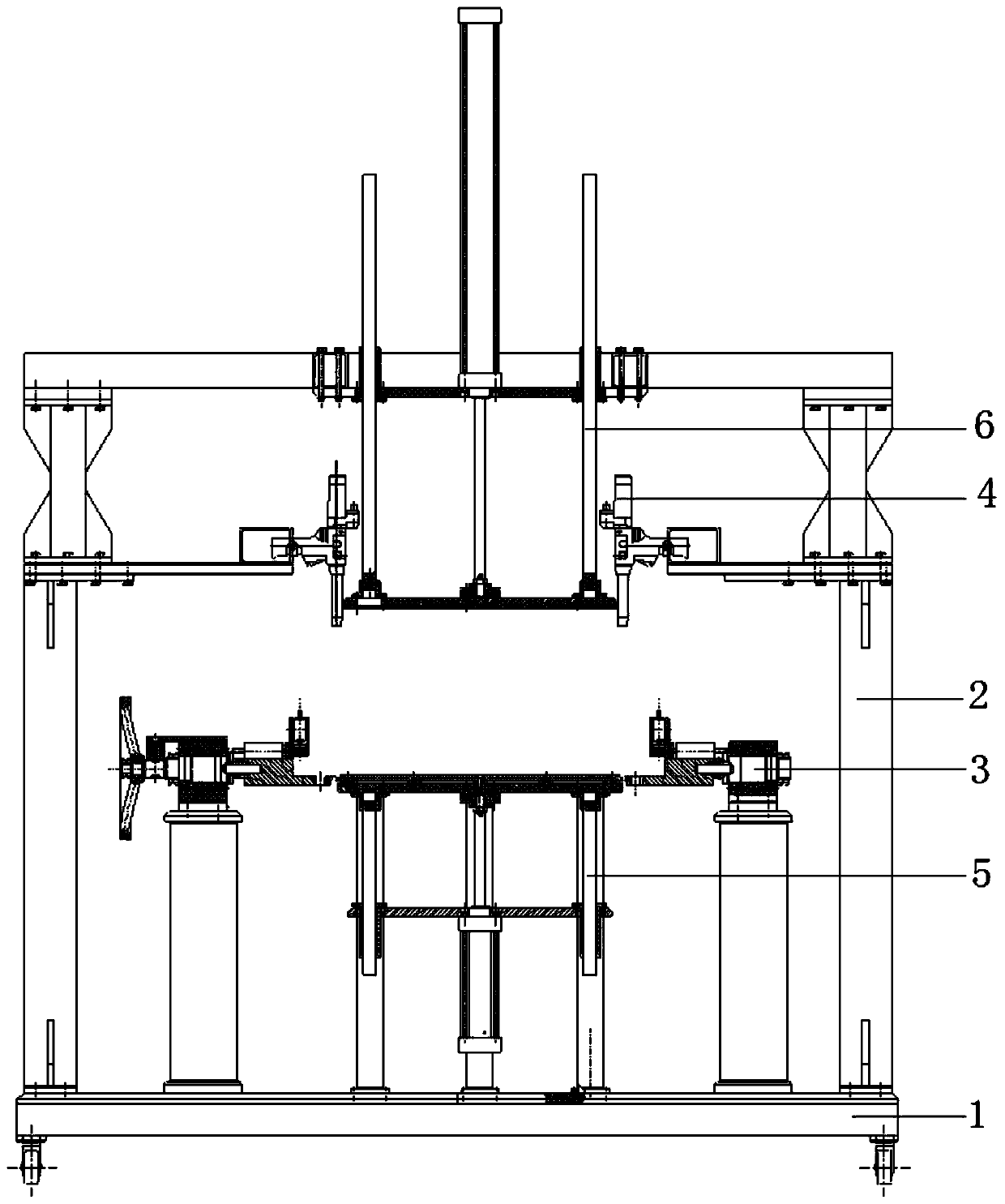

[0037] Such as figure 1 , a double-track welding device for an intercooler, including a base plate 1 and a frame 2, and also includes:

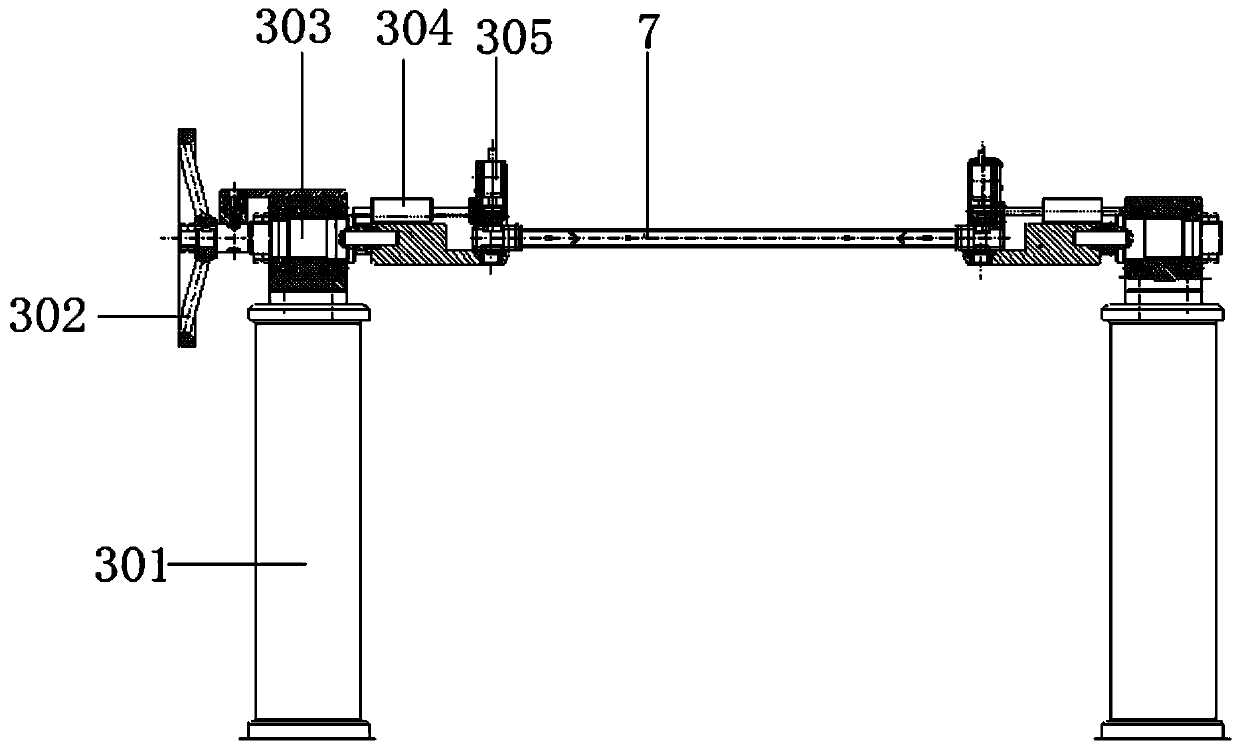

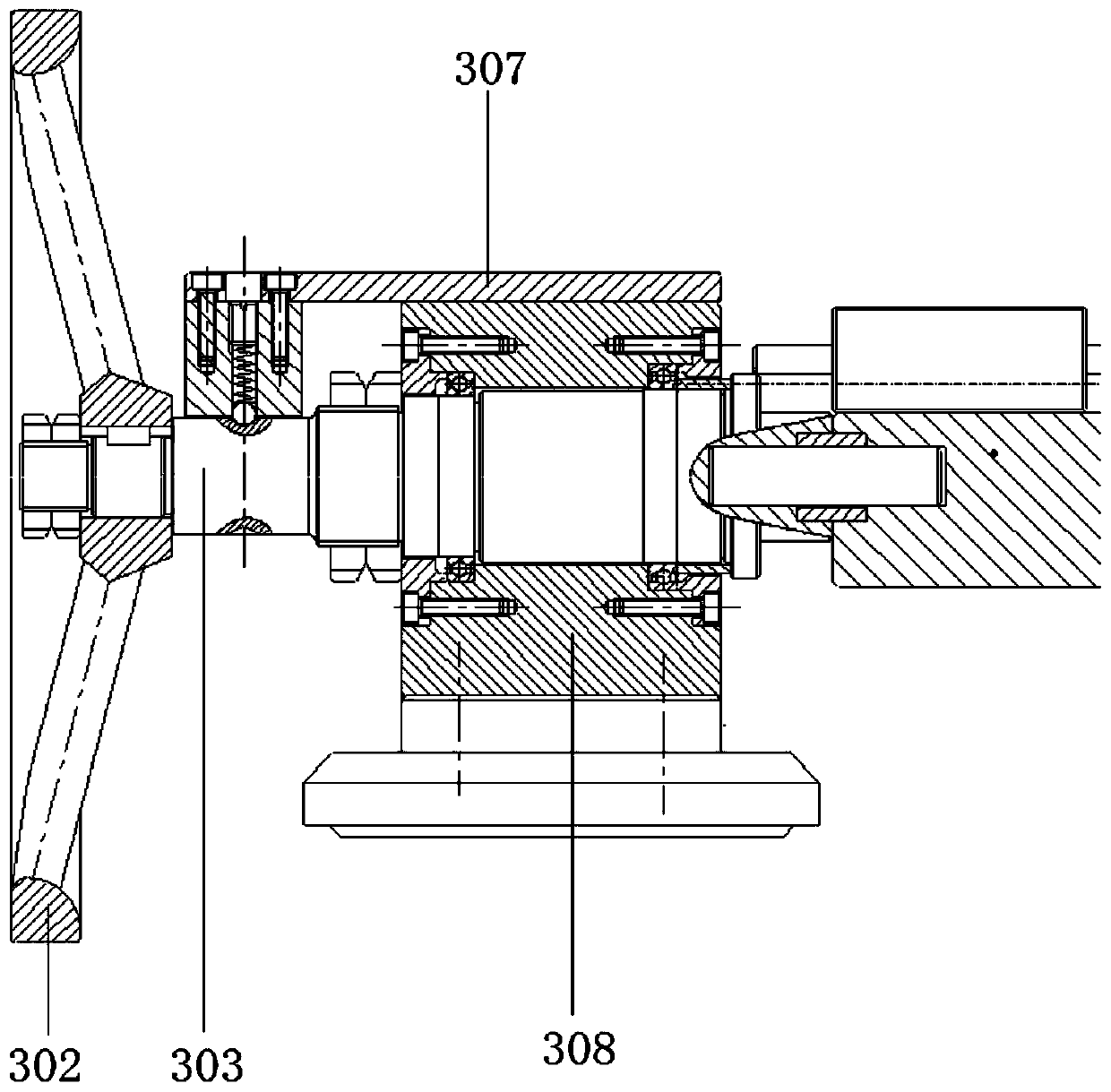

[0038] Rotation positioning unit 3: includes a pair of columns 301 arranged on the base plate 1 at intervals. The columns 301 are provided with a bearing seat 308. The bearing seat 308 is provided with a main shaft 303. Between the main shaft 303 and the bearing seat 308 Bearings are provided, and deep groove ball bearings are used. The main shaft 303 is connected to the positioning rotating seat 306, and the main shaft 303 and the positioning rotating seat 306 are connected by an optical axis.

[0039] refer to Figure 2-4 , The positioning and rotating base 306 is provided with a clamping mechanism for fixing the workpiece 7, and the main shaft 303 and the bearing seat 308 are fastened by a round nut. The positioning rotating seat 306 is provided with a positioning hole that matches the workpiece 7, so that the lower positioning column on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com