Patents

Literature

37results about How to "Guaranteed installation size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

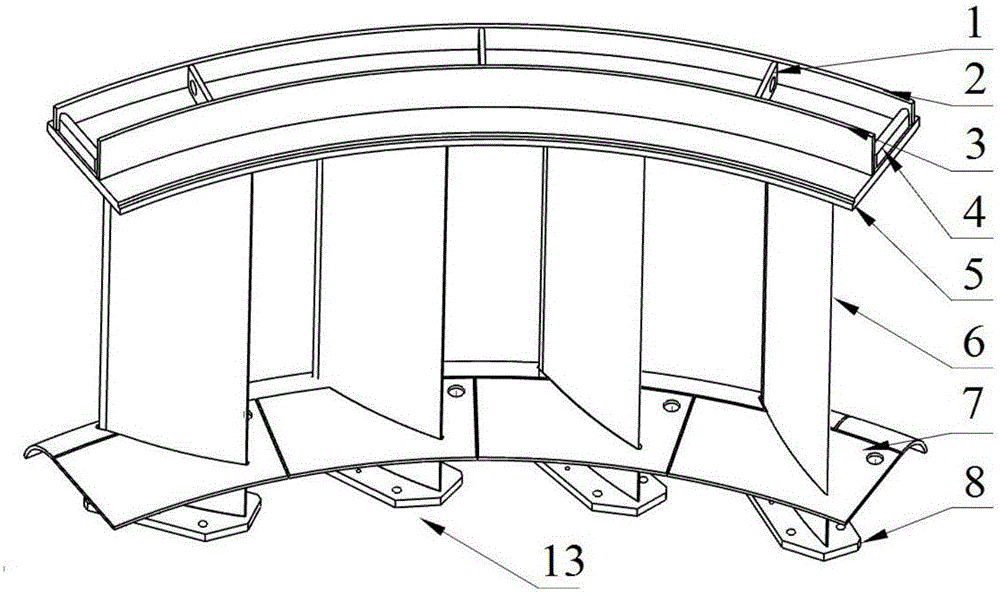

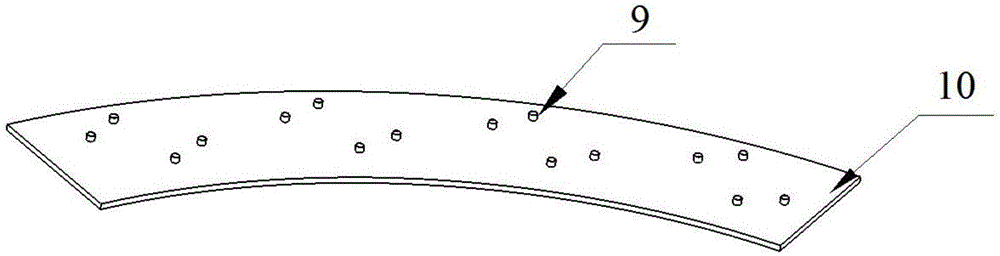

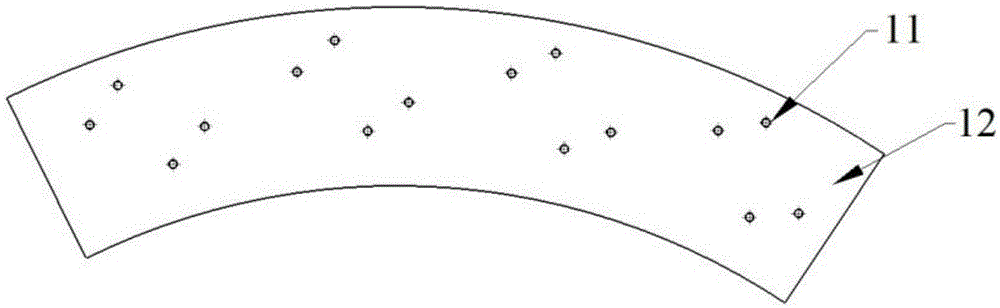

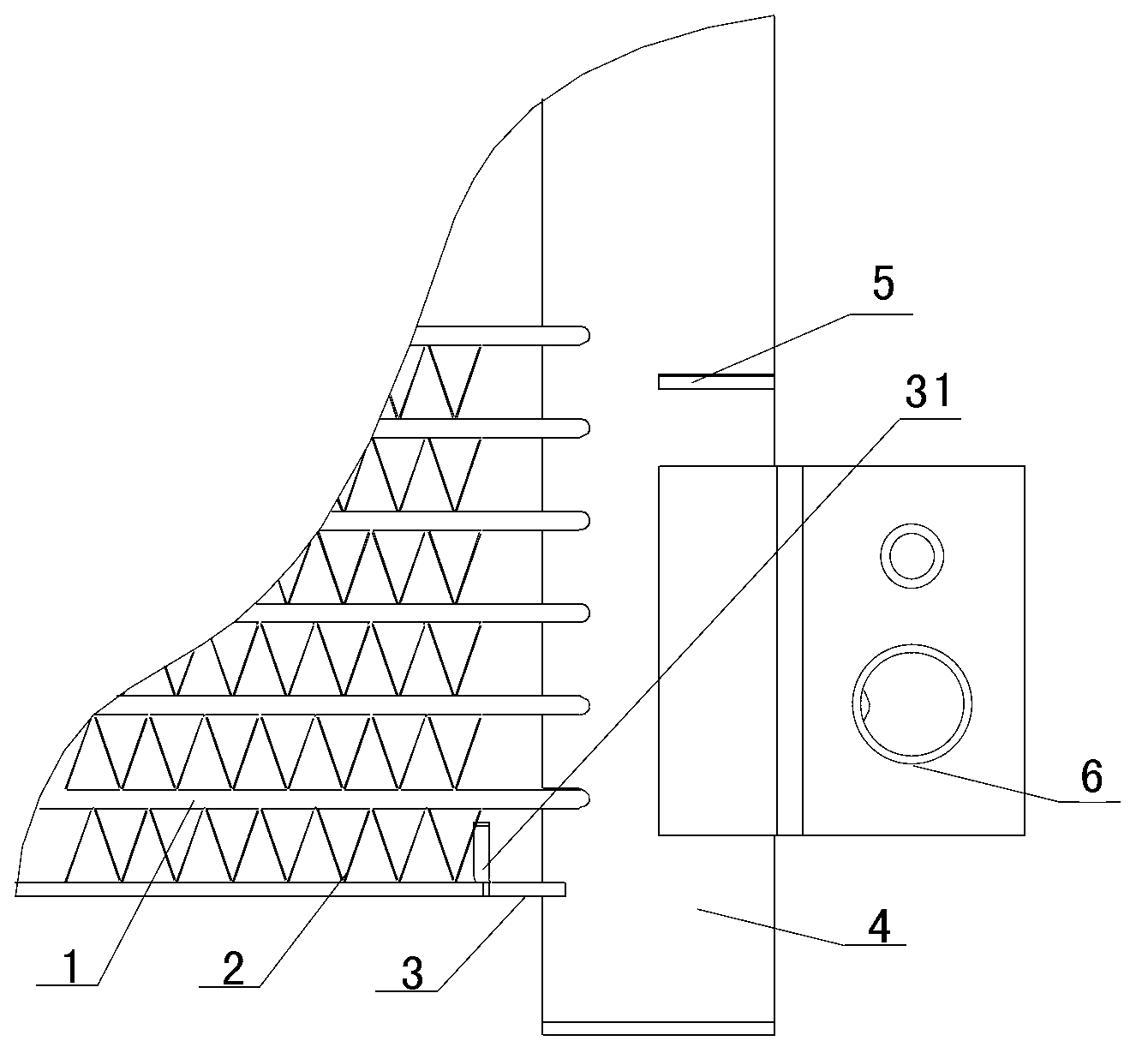

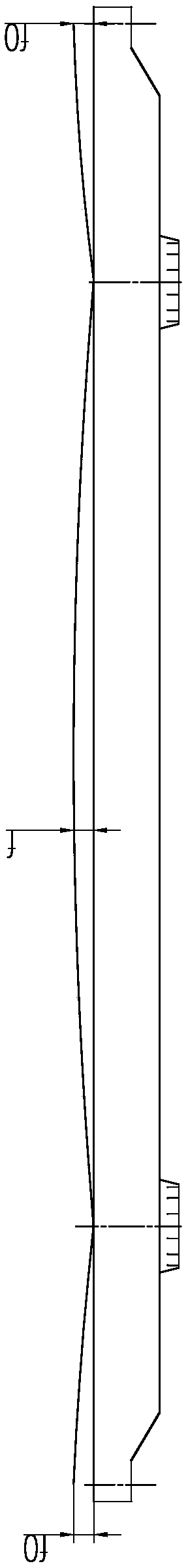

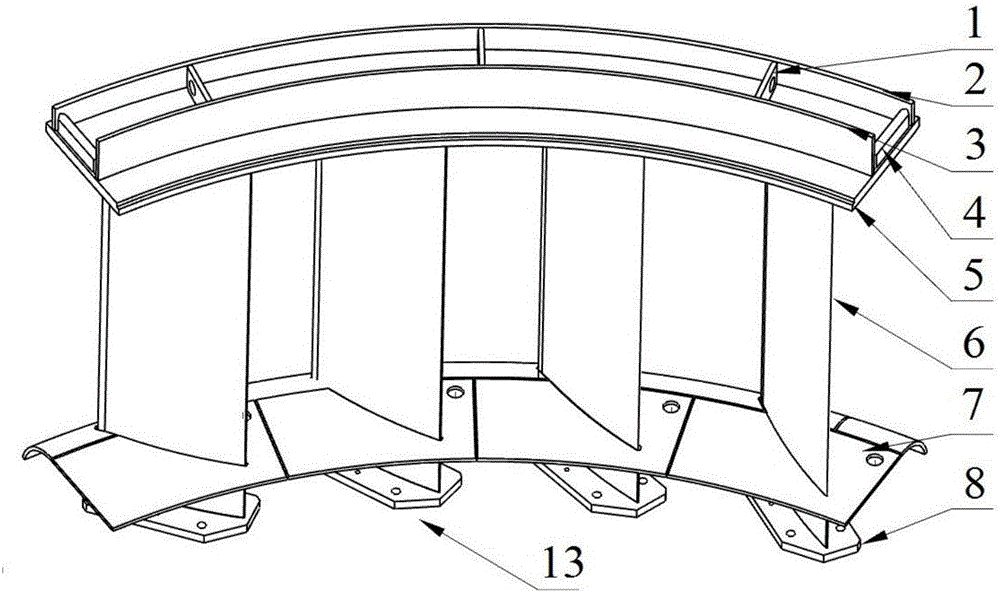

Erecting welding technological method for single-upper-ring type large segmented stand ring with sole plates

ActiveCN105057855AReduce weightReduce difficultyArc welding apparatusProcessing costWelding deformation

The invention relates to an erecting welding technological method for a single-upper-ring type large segmented stand ring with sole plates. A sole plate positioning template and positioning pipes are used for precise positioning; and after splice welding of a lower guide plate, fixed guide vane mounting holes are perforated in a matched mode, and then fixed guide vanes are inserted. The key process problems of stand ring welding deformation, sole plate assembly positioning, sole plate combining through hole processing cost, the production cycle and the like are solved through an auxiliary lower ring, the sole plate positioning templates and the positioning pipes, and the production cost and the production cycle are reduced. According to the stand ring manufactured through the technological method, the problems of assembly positioning, the production cost, welding deformation and the like are effectively solved, and construction site installation requirements are met; the subsequent production cycle and processing cost are greatly reduced, economy and practicability are both considered, and the purposes of lowering cost and improving effects are achieved.

Owner:HARBIN ELECTRIC MASCH CO LTD

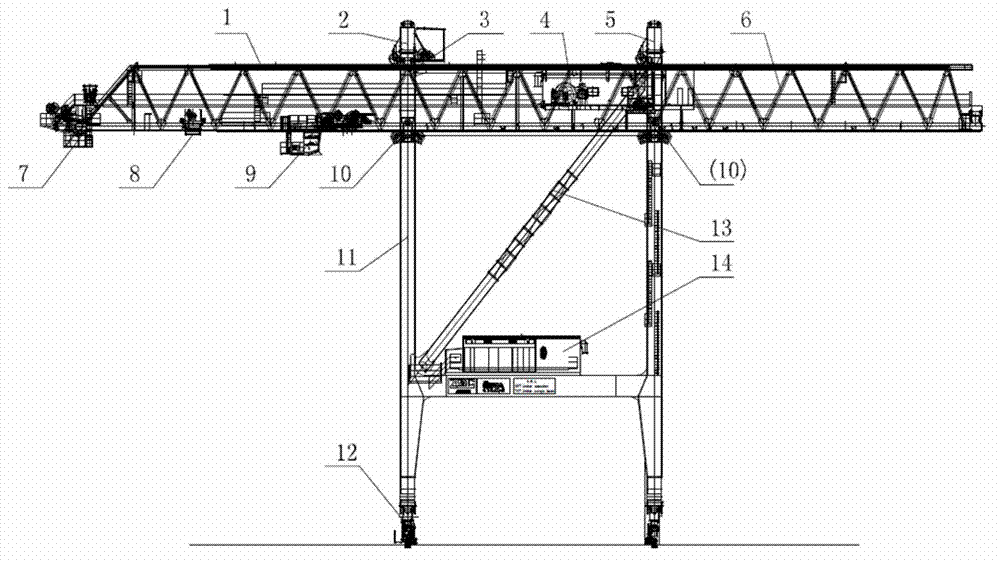

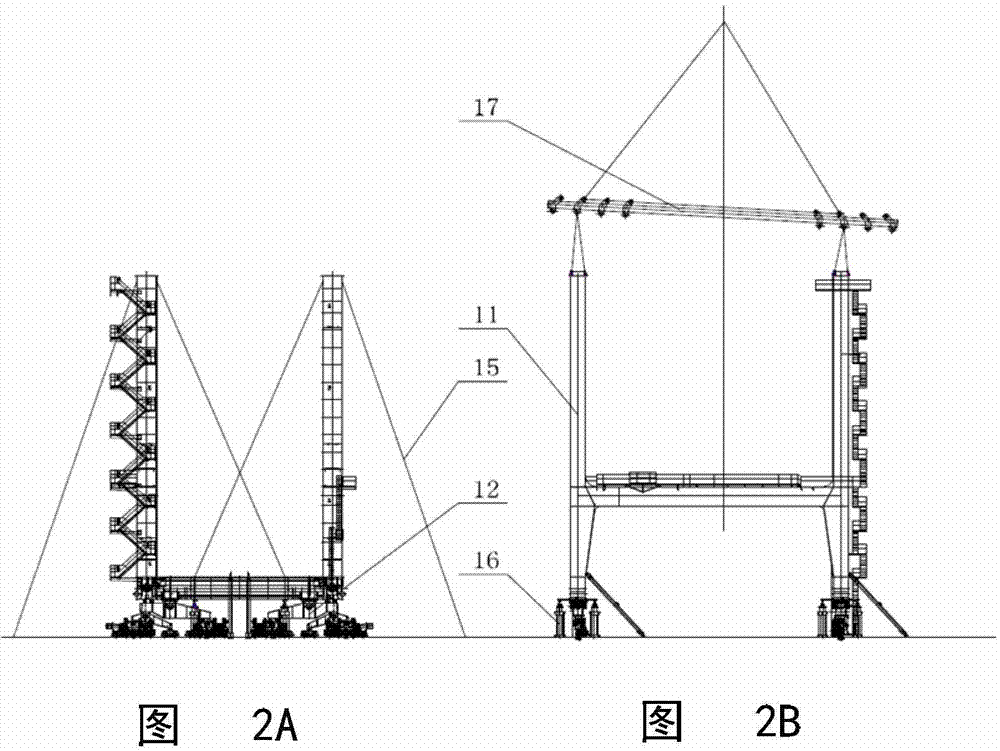

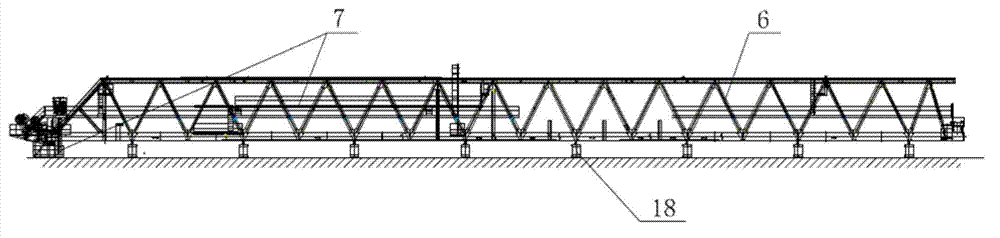

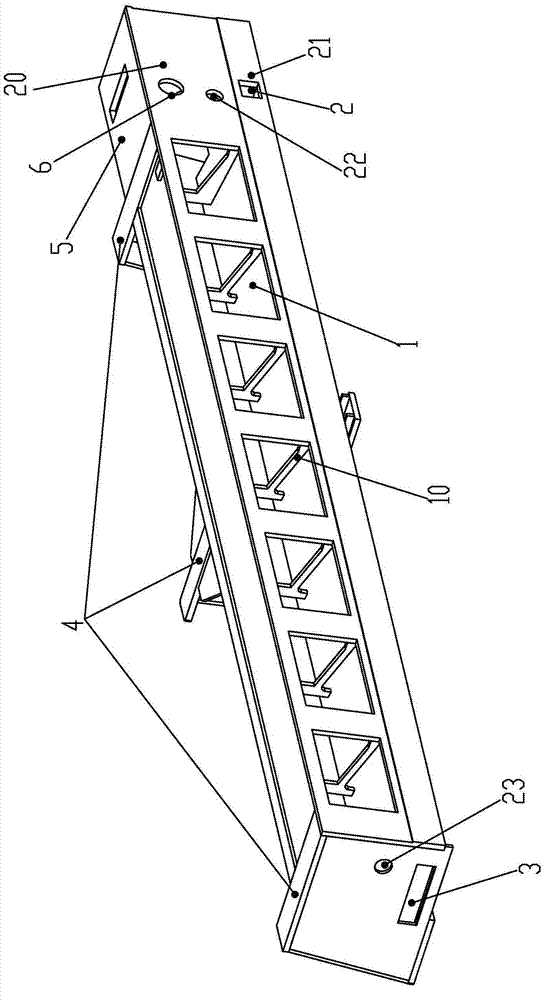

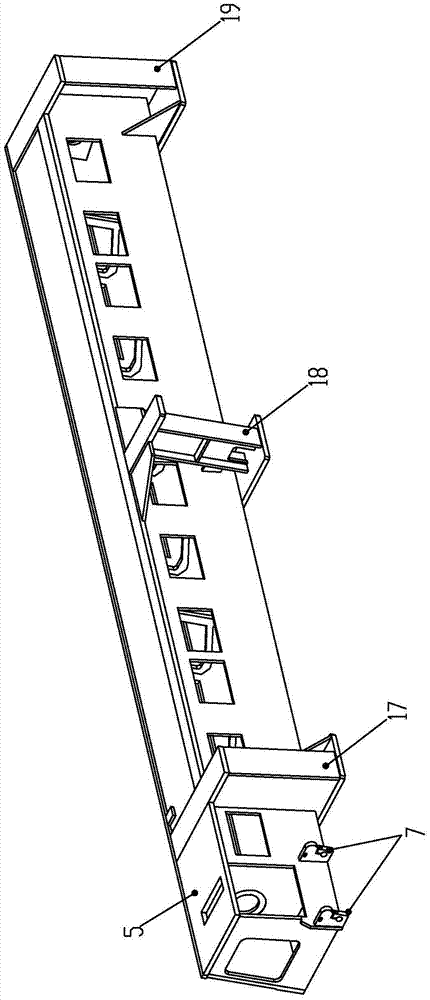

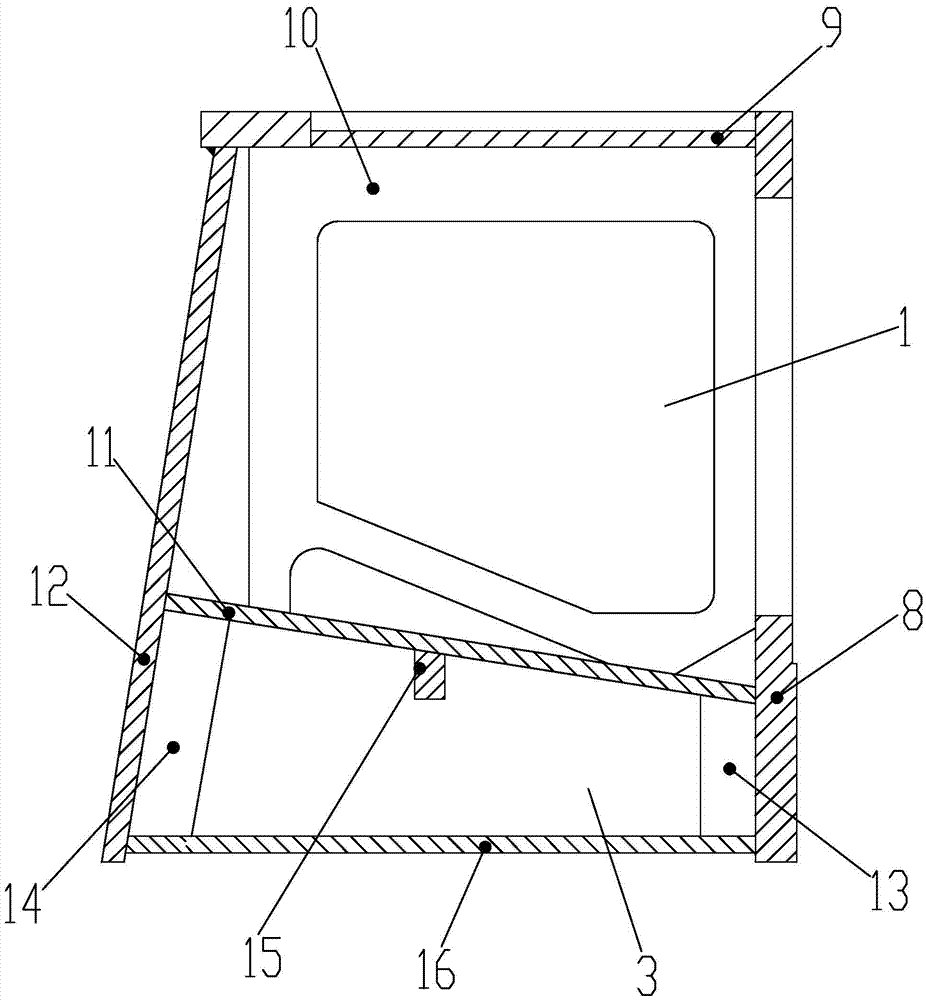

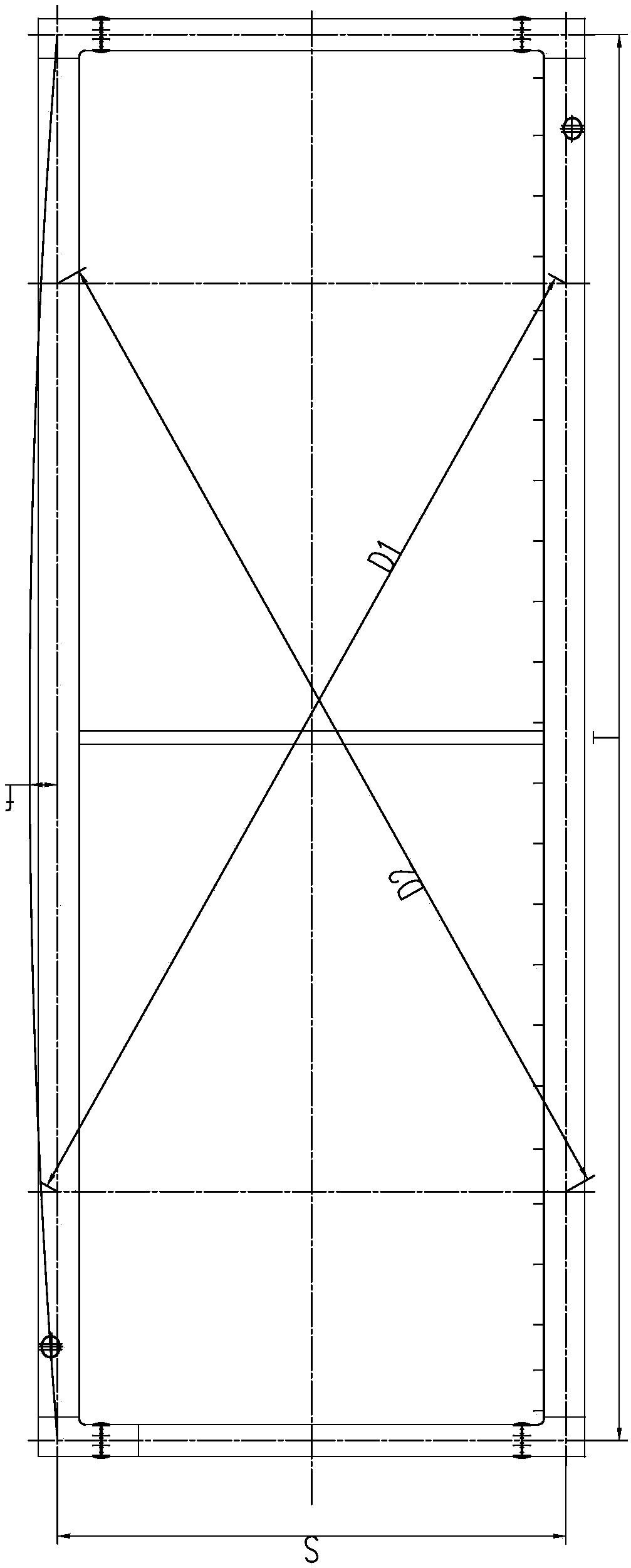

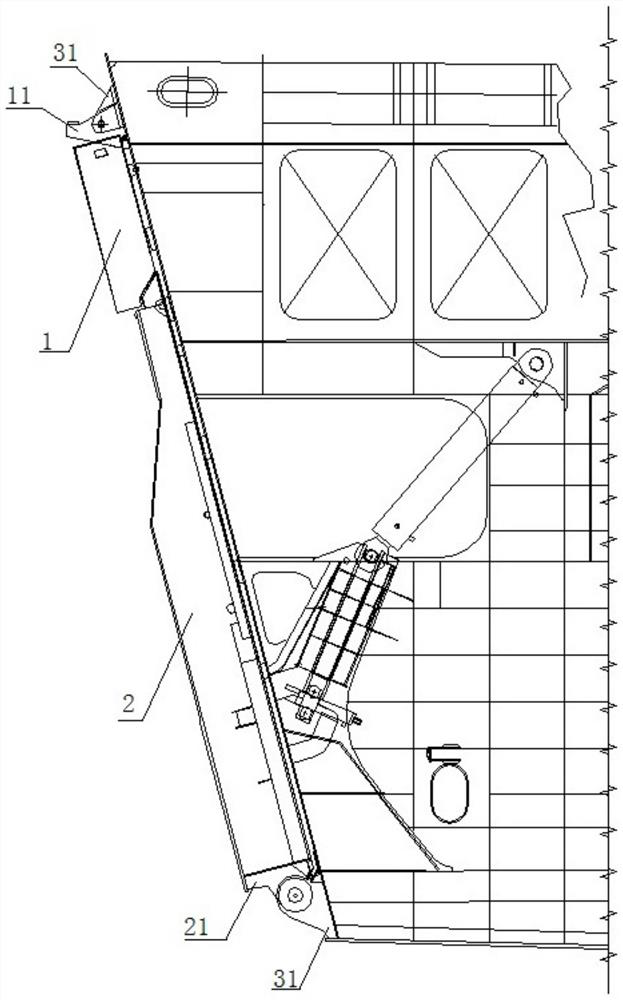

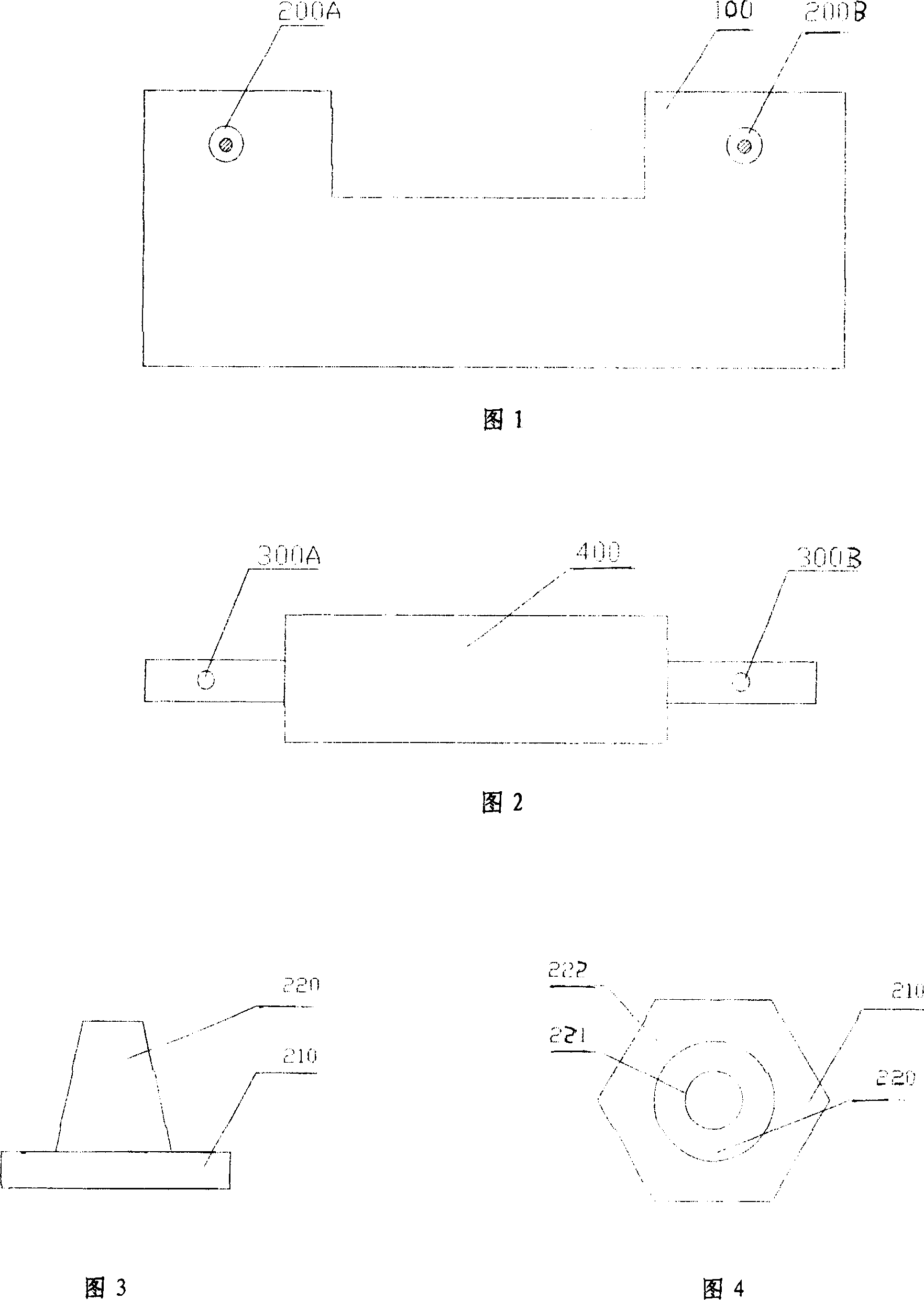

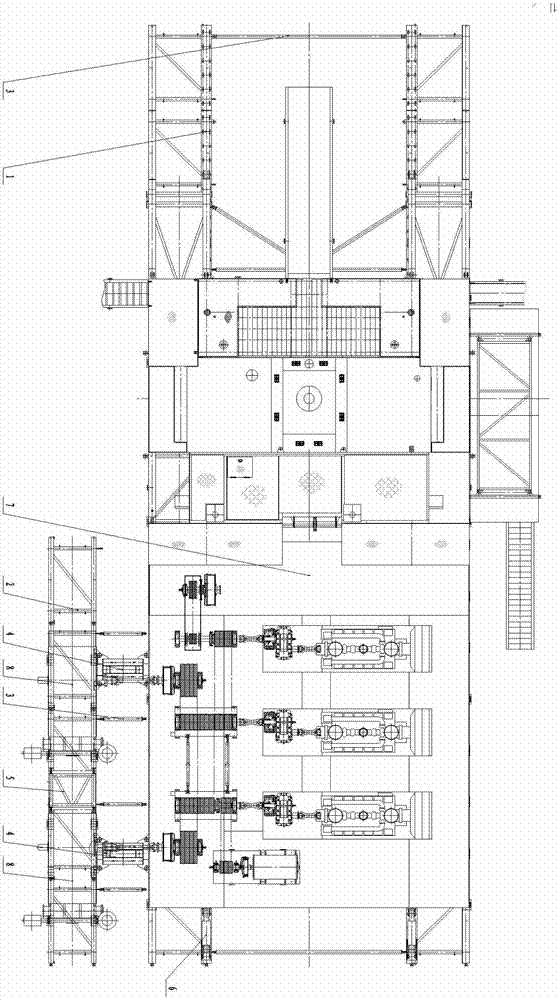

Assembling method of quayside with low posture

ActiveCN103318768AGuaranteed installation sizeReduce high-altitude boring operationsTravelling cranesEngineeringStructural component

The invention provides an assembling method of a quayside with low posture. The method comprises following steps: hoisting a bottom end rail and crane assembly onto a preset general assembly track; hoisting doorframes to the left and the right sides of the bottom end rail, and fixing the doorframes with the bottom end rail; arranging a girder structure assembly on the ground; hoisting a sea side top end rail and a land side top end rail onto the girder structure assembly, and taking the center of the girder structure assembly as datum to adjust the sea side and the land side top end rails; arranging suspension gear assemblies on the sea side and the land side top end rails respectively; and hoisting the girder structure assembly and the sea side and the land side top end rails integrally to the top of the door frames.

Owner:SHANGHAI ZHENHUA HEAVY IND

TD-SCDMA dualpolarization intelligent integral antenna

InactiveCN101552378AReduce weightImprove consistencyAntenna supports/mountingsRadiating element housingsTD-SCDMASilicone adhesive

The invention discloses a TD-SCDMA dualpolarization intelligent integral antenna which comprises an antenna dome, an antenna backboard, a stiffener, a cavity body, a prop and an end cover. A grab is arranged on the antenna dome; a clamping slot matched with the grab is arranged on the stiffener; and the antenna dome and the stiffener are tightly clamped by the matched use of the grab and the clamping slot. The TD-SCDMA dualpolarization intelligent integral antenna has light entire weight, does not need to be fastened by bolts, can accomplish excellent sealing and water prevention only by filling less silicone adhesive, has good consistency and high production efficiency during production, and improves the first-time qualification rate of products.

Owner:JIANGSU JST RF SYST

Production process for aluminum alloy window sectional material

ActiveCN110665986AEffective straighteningAccurate flatnessShaping toolsExtrusion control devicesIngotWater cooling

The invention discloses a production process for an aluminum alloy window sectional material. The production process for the aluminum alloy window sectional material comprises the following steps: A1,cast ingot preparation; A2, soaking; A3, raw material preheating; A4, extrusion forming: an aluminum alloy cast ingot is extruded through an extruder, the aluminum alloy cast ingot is extruded by theextruder, so that the aluminum alloy cast ingot in an extrusion barrel is enabled to extrude towards an extrusion die and extruded out from a die hole of the extrusion die, and in the process, the temperature of the extrusion die is controlled to be 380 DEG C; A5, preliminary cooling: water cooling is adopted, and the extruded aluminum alloy section material is cooled to be 250-300 DEG C; A6, rolling straightening: the surface of the aluminum alloy section material is rolled through a straightening machine, so that the surface of the aluminum alloy section material is straight; A7, aftercooling: air cooling is adopted, and the aluminum alloy section material is cooled to be 200 DEG C and below; A8, heat treatment; and A9, surface treatment. The production process for the aluminum alloy window sectional material has the following advantage and effect: due to the production process, the accuracy of the straightness and the surface planeness of the aluminum alloy section material is increased, so that a guarantee on the installation dimensions of an aluminum alloy window prepared from the aluminum alloy sectional material is benefited.

Owner:无锡辰浩建筑节能科技有限公司

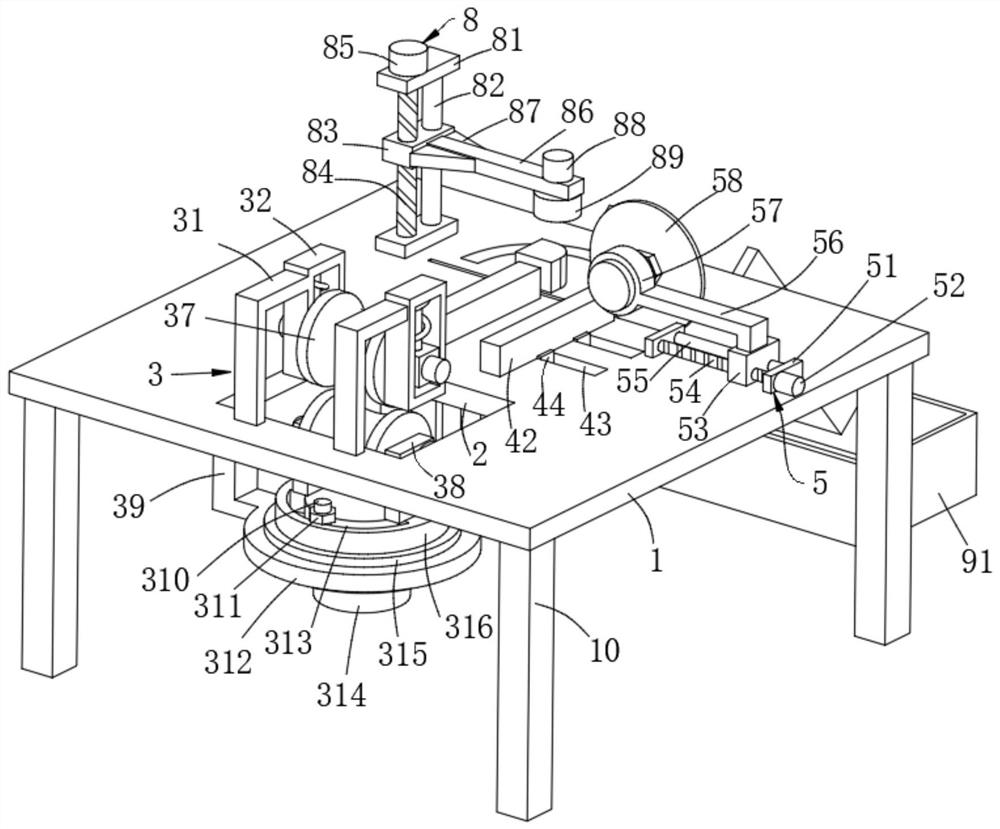

Aluminum alloy profile machining system

ActiveCN113182968AGuaranteed stabilityGuaranteed installation sizeEdge grinding machinesGrinding drivesEngineeringStructural engineering

The invention provides an aluminum alloy profile machining system. The system comprises a table plate, a profile feeding unit, a profile bending unit, a bending angle blocking unit and a bending and grinding unit; a through groove is formed in one side of the top of the table plate; the profile feeding unit comprises a feeding assembly, a speed control assembly and a buffering assembly and is mounted at the through groove in the table plate; the profile bending unit comprises an execution assembly and a power transmission assembly and is mounted on the side, away from the through groove, of the table plate; the bending angle blocking unit is mounted on the side, close to the profile bending unit, of the table plate; and the bending and grinding unit is mounted on the table plate and corresponds to the bending angle blocking unit. The feeding assembly can clamp and rotate an aluminum alloy profile oppositely to drive the aluminum alloy profile to move forwards, the power transmission assembly can drive the execution assembly to bend the aluminum alloy profile, the bending angle blocking unit can control the bending angle of the aluminum alloy profile to be a round angle or a right angle, the bending and grinding unit can flatten or grind wrinkles generated in the bending position, and the mounting size and the external attractiveness of the profile are ensured.

Owner:ZHEJIANG TOP CASTING MACHINERY TECH

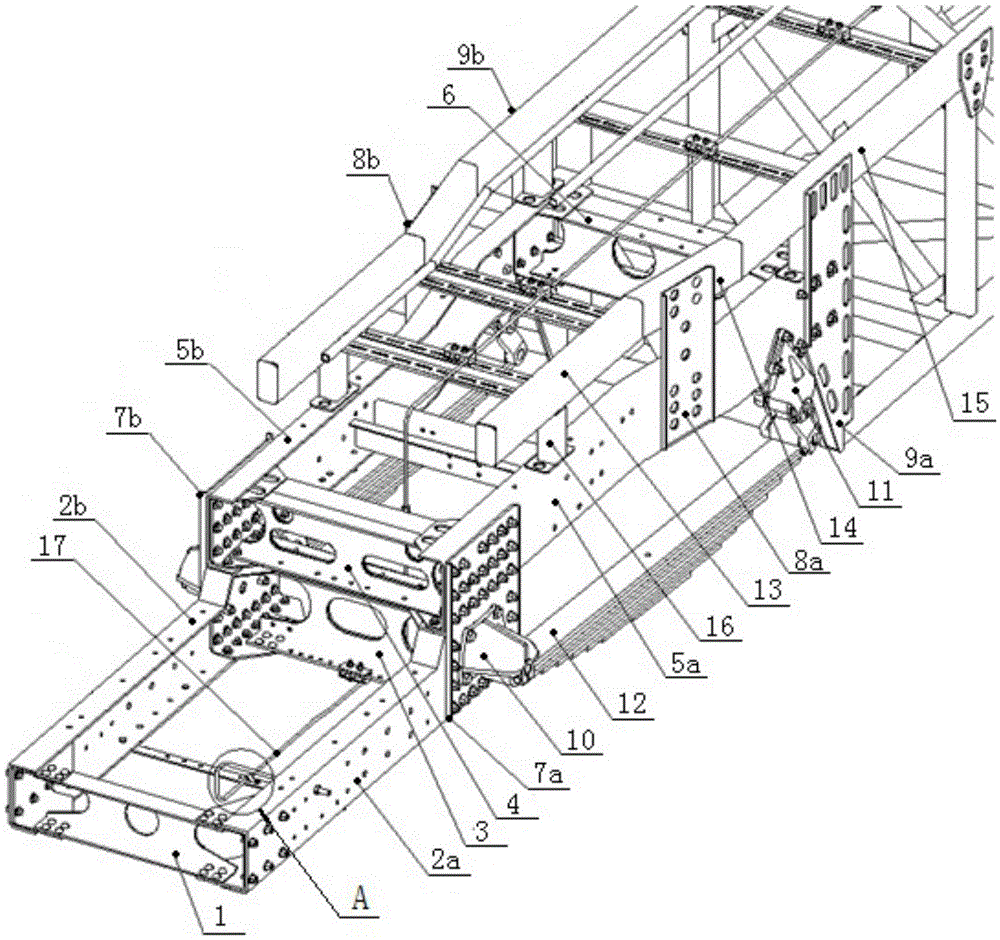

Front-section assembly of leaf spring suspension chassis frame of low drive zone passenger car

ActiveCN105584529AGuaranteed installation sizeGuaranteed installation heightUnderstructuresSteel tubeVehicle frame

The invention discloses a front-section assembly of a leaf spring suspension chassis frame of a low drive zone passenger car. The front-section assembly is composed of two parts including the lower main part and the upper main part. The lower main part is formed by connecting a first cross beam assembly, a first left longitudinal beam, a first right longitudinal beam and a second lower cross beam assembly through bolts and nuts. The upper main part is formed by connecting a second upper cross beam assembly, a second left longitudinal beam, a second right longitudinal beam and a third cross beam assembly through bolts. By the adoption of the front-section assembly, the longitudinal beams on the front section of the frame are formed by connecting upper sections with lower sections, and connecting positions are reinforced through an upper cross beam, a lower cross beam and side connecting boards. The second left longitudinal beam and the second right longitudinal beam on the front section of the frame are of bent structures. Longitudinal beam steel pipes on the middle section of the frame are arranged of the same-form structure. Steel pipe transition positions are welded. The bent portions of the second left longitudinal beam and the second right longitudinal beam on the front section of the frame are reinforced through additionally-arranged connecting boards. The first left longitudinal beam and the first right longitudinal beam on the front section of the frame are of the sectional structures with the rear portions higher than the front portions. The front-section assembly has the beneficial effects of being simple in structure, firm, stable, convenient to assemble, low in cost and high in universality.

Owner:SINO TRUK JINAN POWER

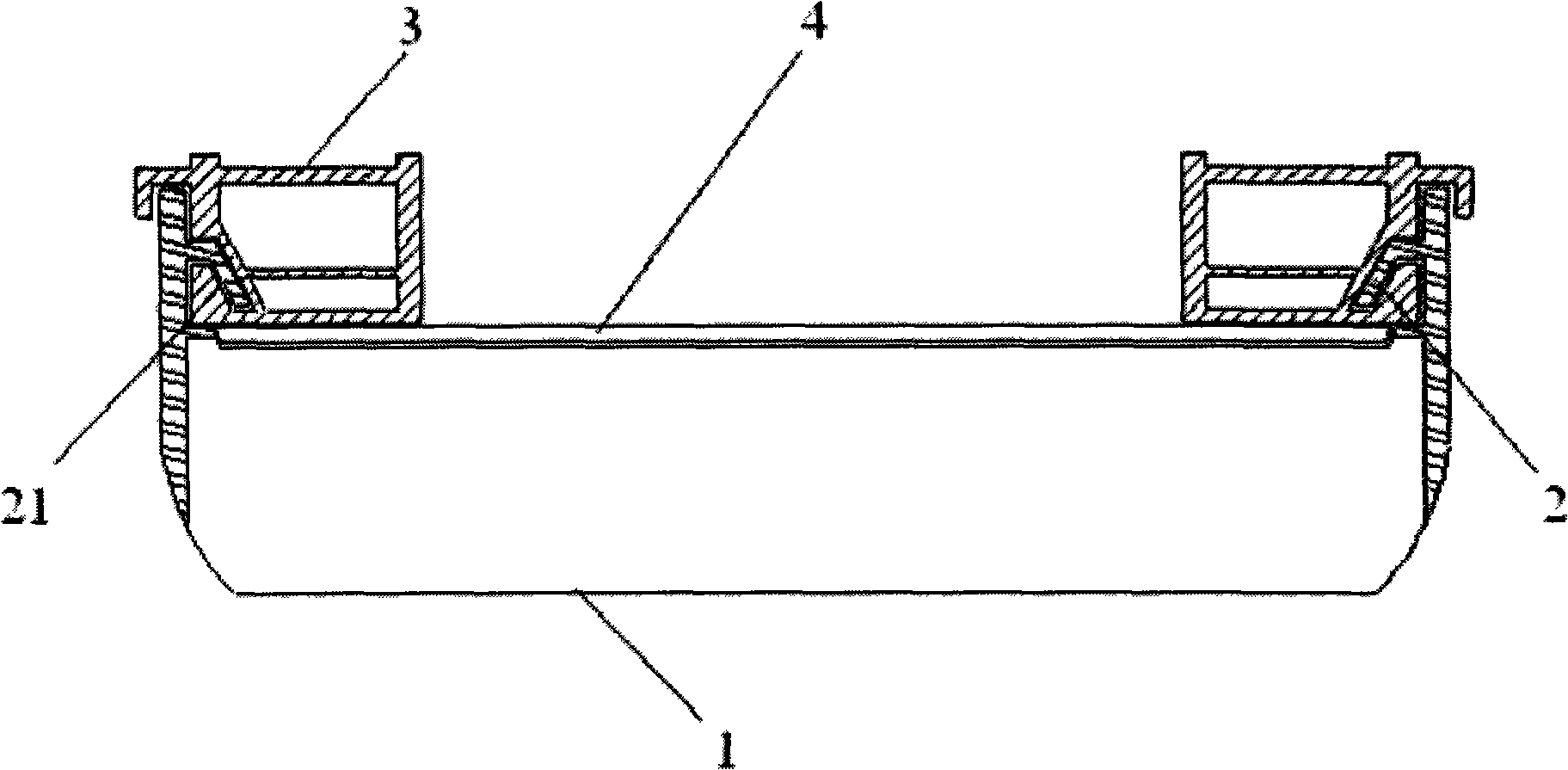

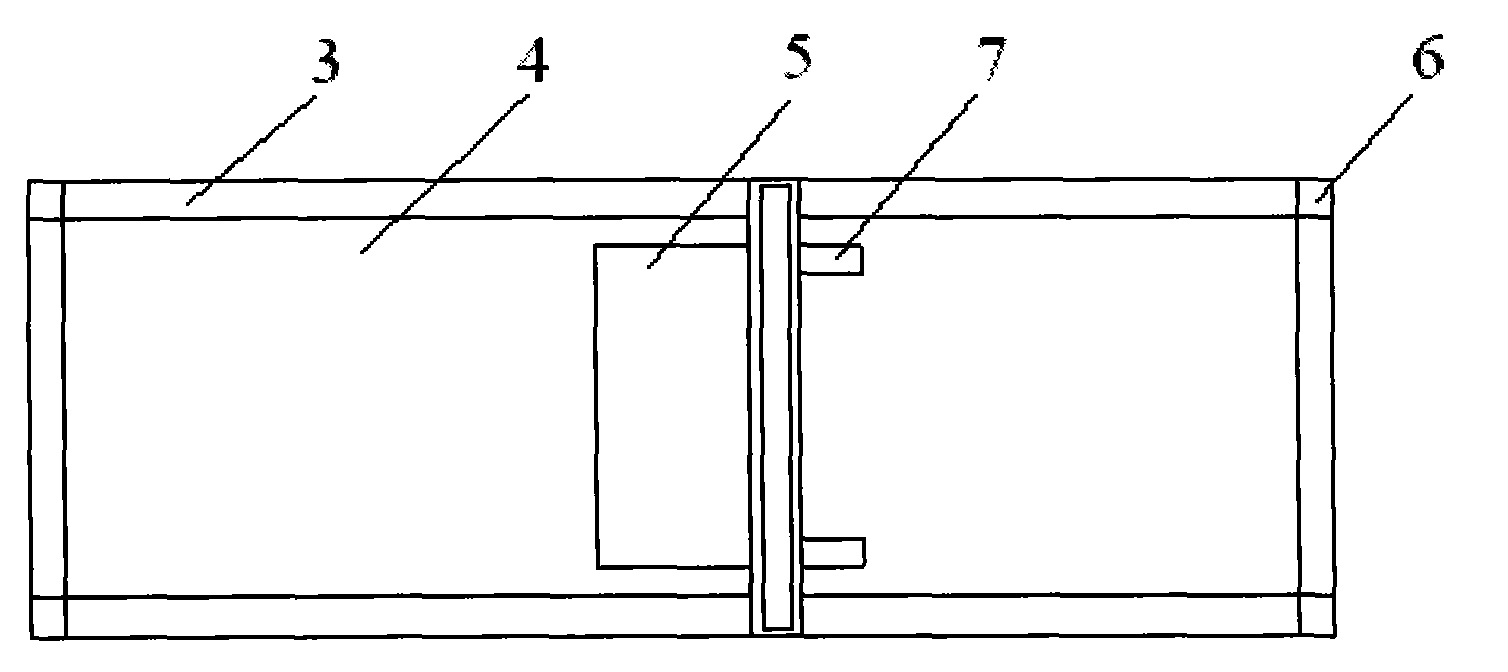

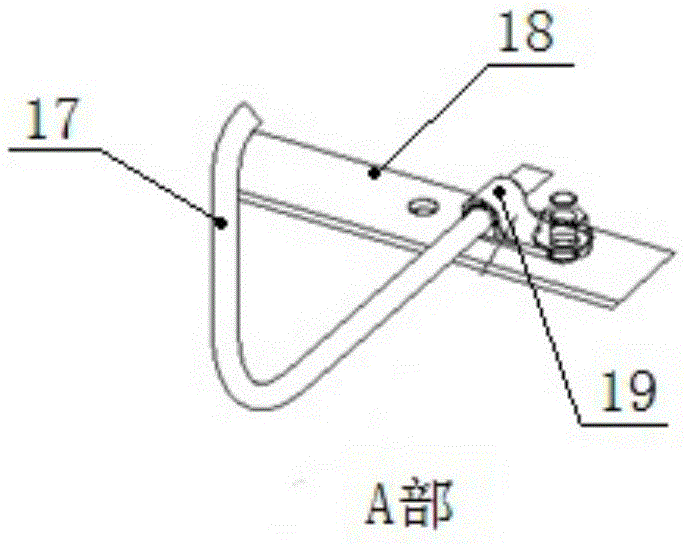

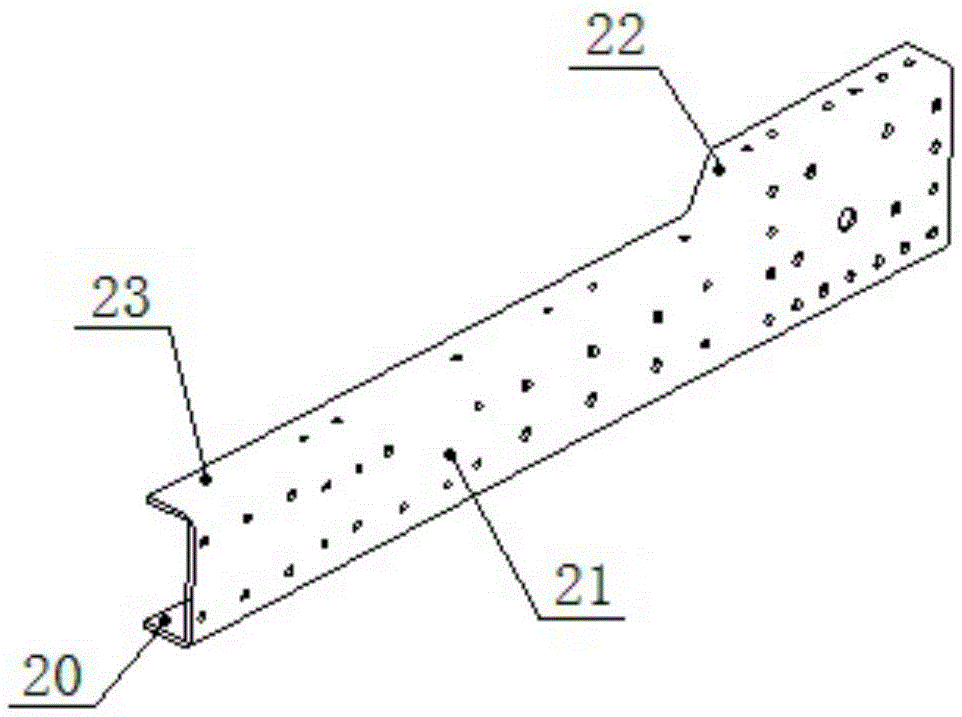

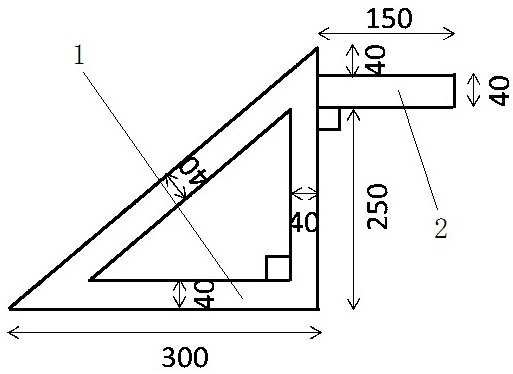

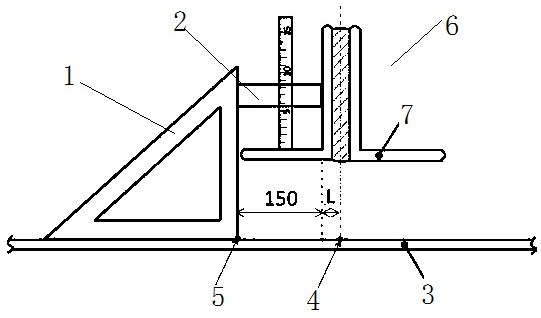

Method for improving installation precision of guide rails on bulkhead plate of transverse bulkhead

PendingCN111746754AGuaranteed installation sizeHorizontal installation at the same heightWaterborne vesselsMechanical engineeringWall plate

The invention discloses a method for improving installation precision of a guide rail on a bulkhead plate of a transverse bulkhead, the method is based on an auxiliary tool, and the auxiliary tool comprises a right-angle part; a rectangular part, the first end of the rectangular part is perpendicularly connected to one right-angle side of the right-angle part, and the second end of the rectangular part extends in the direction away from the right-angle part; the method comprises the steps of arranging wall plates of the transverse bulkhead horizontally; defining a guide rail center line on the wall plate; defining offset lines at predetermined distances on two sides of the center line of the guide rail; placing a guide rail; adjusting guide rail position, when the right-angle point of the right-angle part is aligned with the two offset lines from the two sides of the guide rail respectively, attaching the second ends of the rectangular part to the outer walls of the two sides of theguide rail respectively, wherein the measured fall values of the bottom edge of the rectangular part and the two sides of the guide rail are equal.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

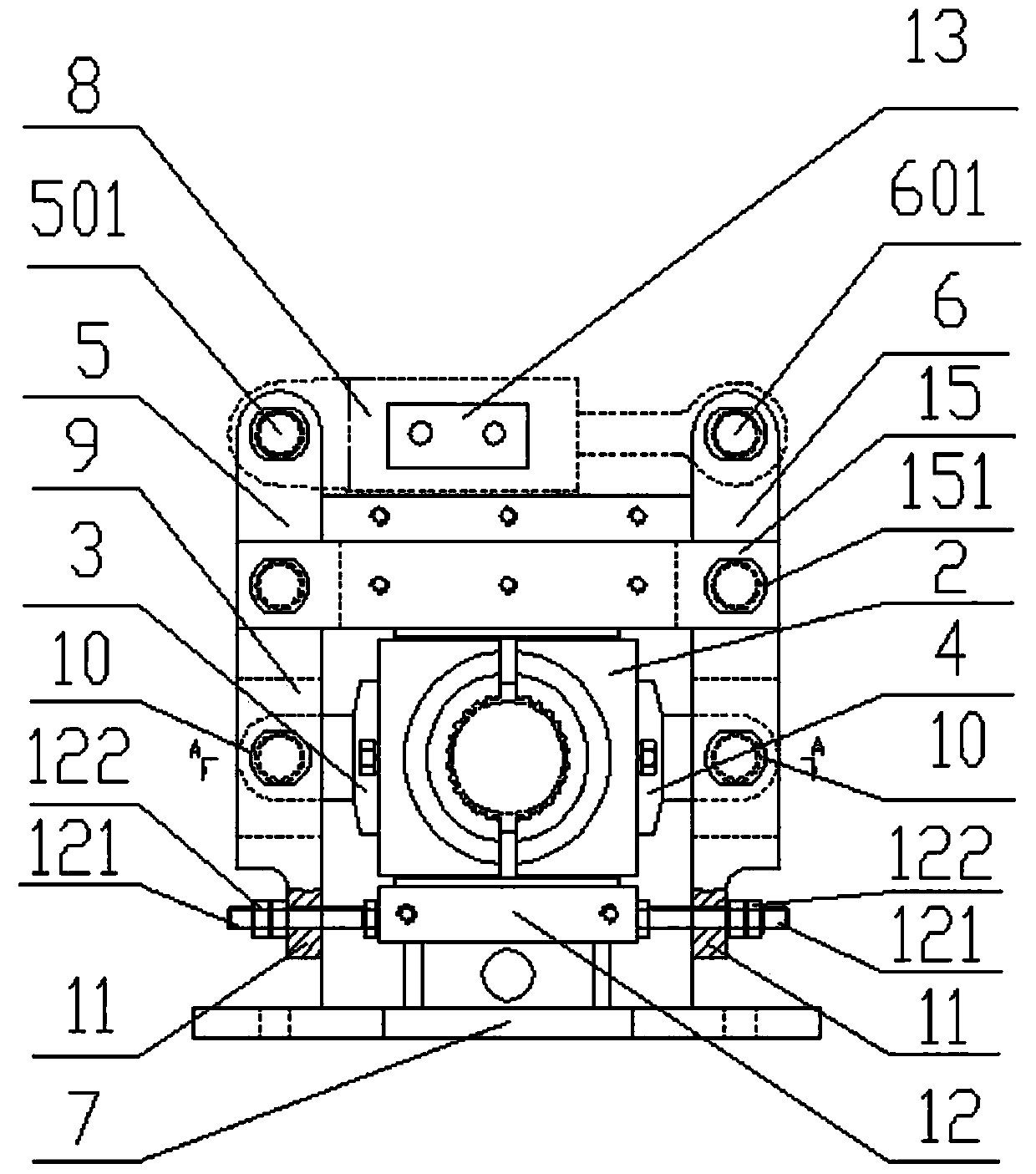

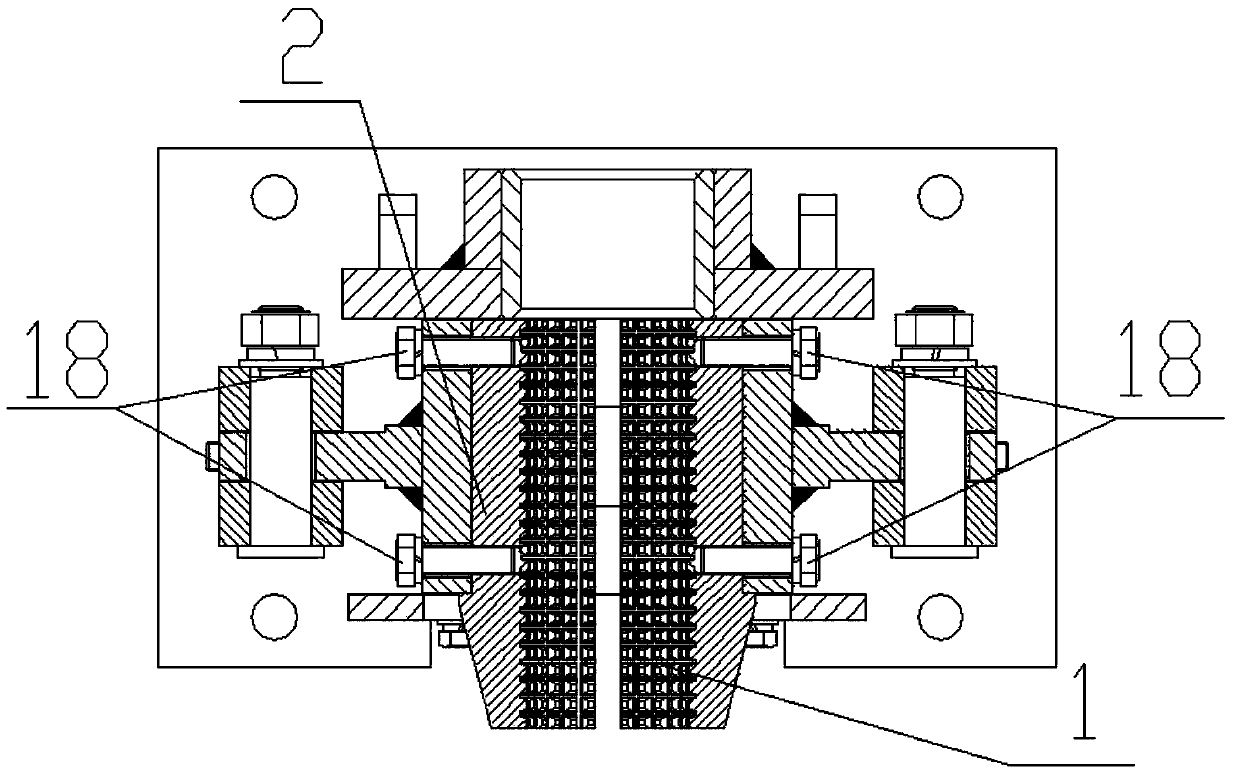

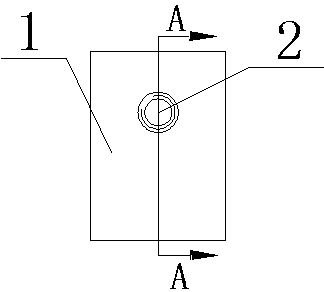

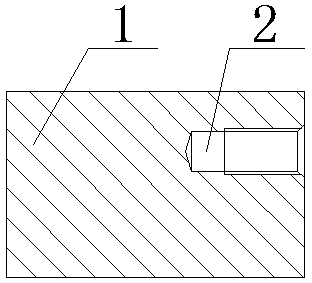

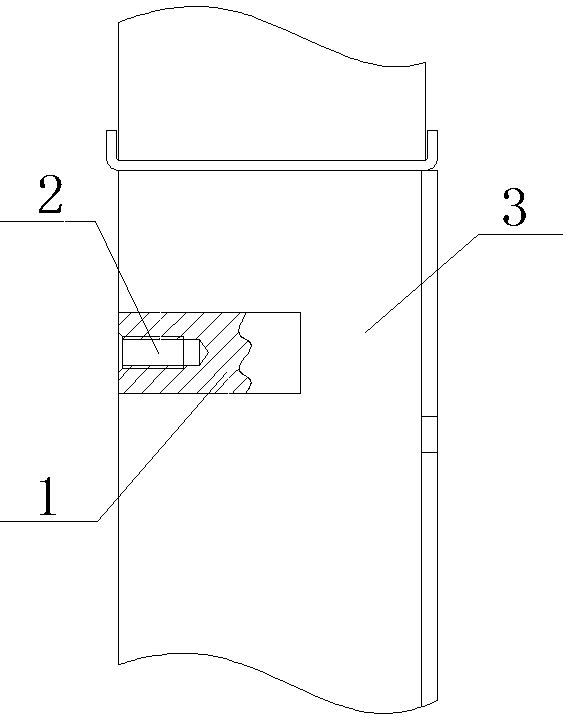

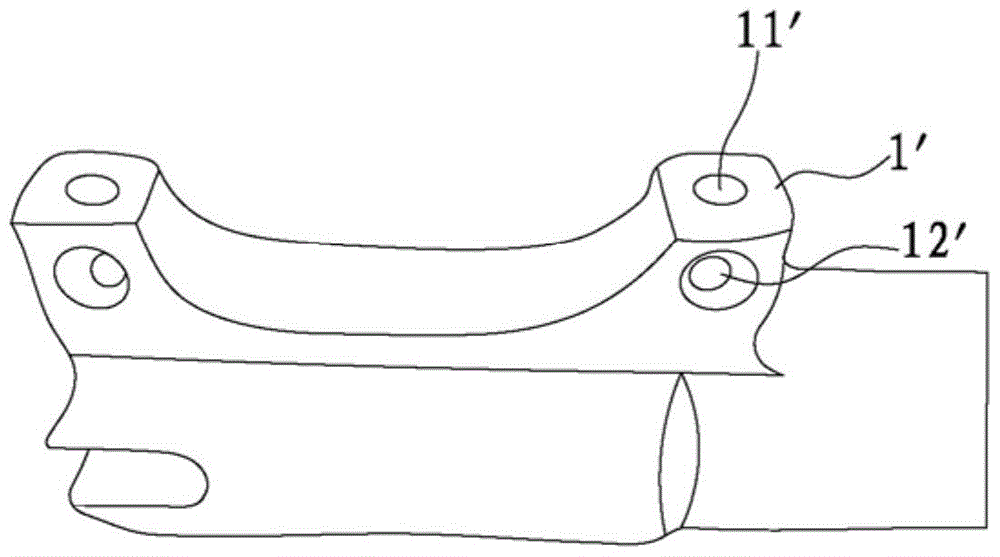

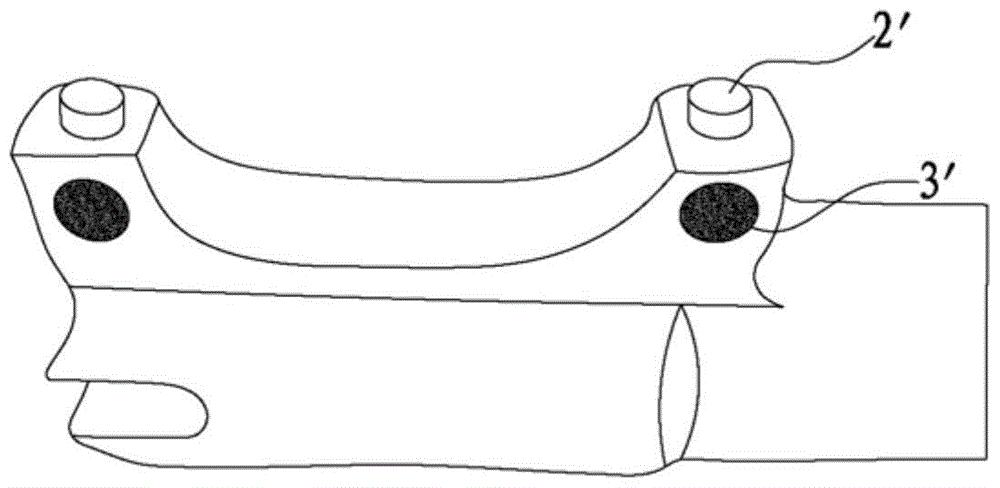

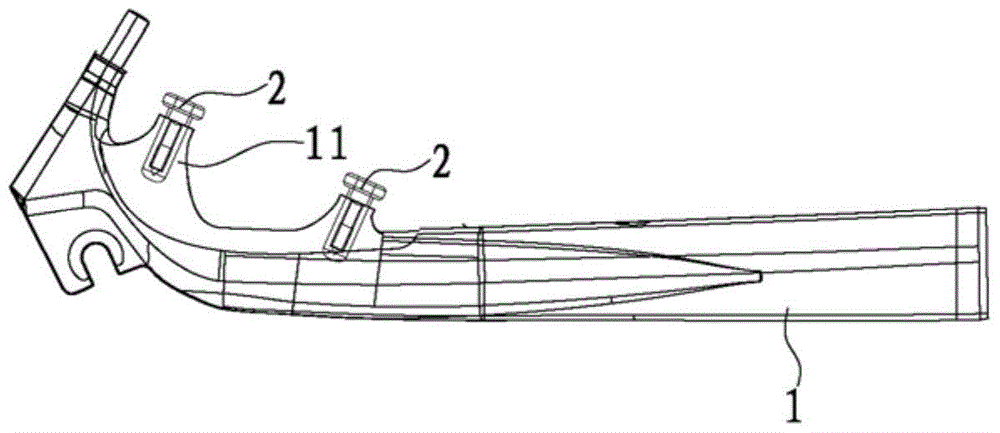

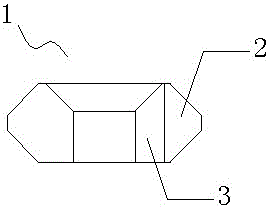

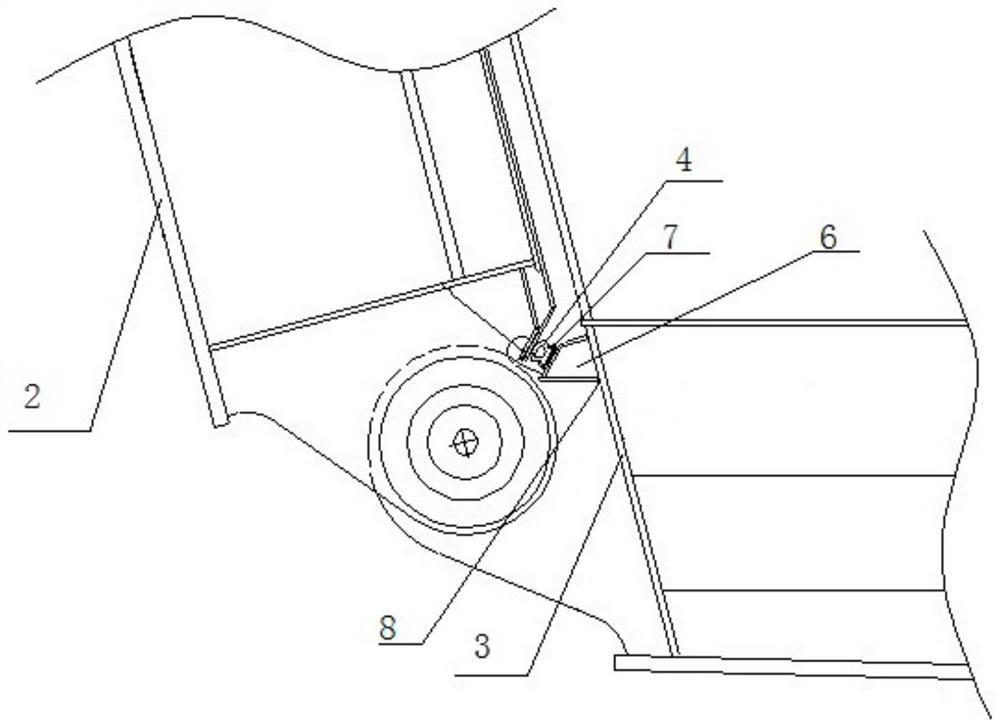

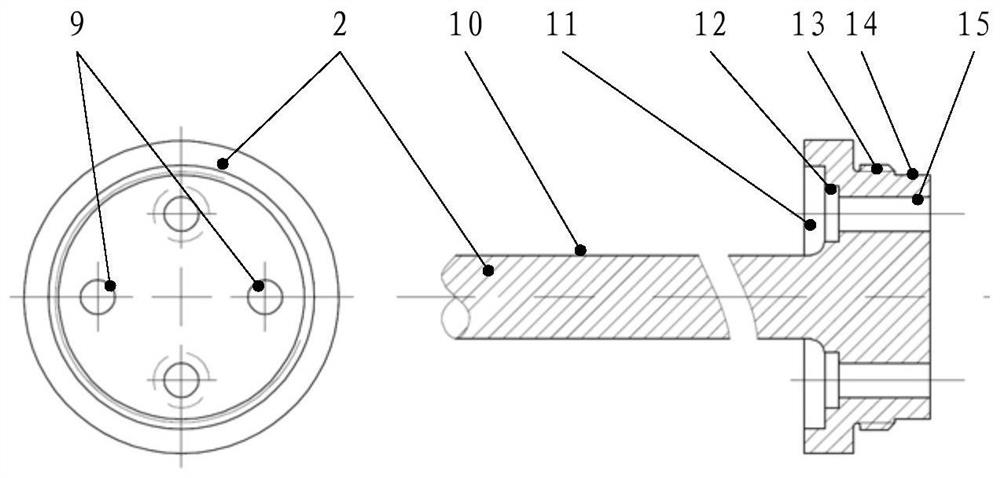

Drill rod clamp mechanism

ActiveCN104196469AReduce manufacturing difficultyGuaranteed parallelismDrilling rodsDrilling casingsEngineeringDrill

The invention relates to a drill rod clamp mechanism which comprises a drill rod clamping groove, a clamping rod sleeve, a first clamping block, a second clamping block, a first rocking arm, a second rocking arm, a support and a hydraulic oil cylinder. The clamping rod sleeve is arranged on the outer portion of the drill rod clamp groove in a sleeved mode. The first clamping block and the second clamping block are arranged on the outer side of the clamping rod sleeve opposite to each other. The first rocking arm and the second rocking arm are connected with the first clamping block and the second clamping block respectively. The hydraulic oil cylinder is arranged between the first rocking arm and the second rocking arm. Opening-closing moving of the first rocking arm and the second rocking arm is driven by stretching of the hydraulic oil cylinder. According to the drill rod clamp mechanism, opening and closing of the drill rod clamp mechanism can be controlled only through the hydraulic oil cylinder, the manufacturing difficulty of the drill rod clamp mechanism is lowered, the mounting size and the mounting shaft parallelism of the hydraulic oil cylinder can be well guaranteed, cost is saved, and maintaining is convenient.

Owner:广西华力重工股份有限公司

Anti-rotating condenser welding process

The invention discloses an anti-rotating condenser welding process. A condenser comprises a core and a liquid collecting pipe, the core comprises flat pipes and fins which are arranged at intervals, a support plate is arranged at the bottom of the core, and two ends of each flat pipe are inserted into the liquid collecting pipe. The welding process includes the steps: firstly, preliminarily fixing two ends of the support plate and the liquid collecting pipe by spot welding; and secondly, placing the spot-welded condenser into a brazing furnace for integral brazing. By the aid of the anti-rotating condenser welding process, the support plate and the liquid collecting pipe are preliminarily fixed by spot welding to form a frame, the core comprising the flat pipes and the fins is stably kept in the frame, the flat pipes are constantly inserted into the liquid collecting pipe when the condenser is placed into the brazing furnace for brazing, welding strength of the flat pipes and the liquid collecting pipe is ensured, uniformity of the diagonal size of the core is effectively controlled, rotation of the liquid collecting pipe is prevented by preliminary spot-welding fixing, mounting sizes of a pressing plate and a support are ensured, and the quality of the condenser is improved.

Owner:JIANGSU JIAHE THERMAL SYST RADIATOR

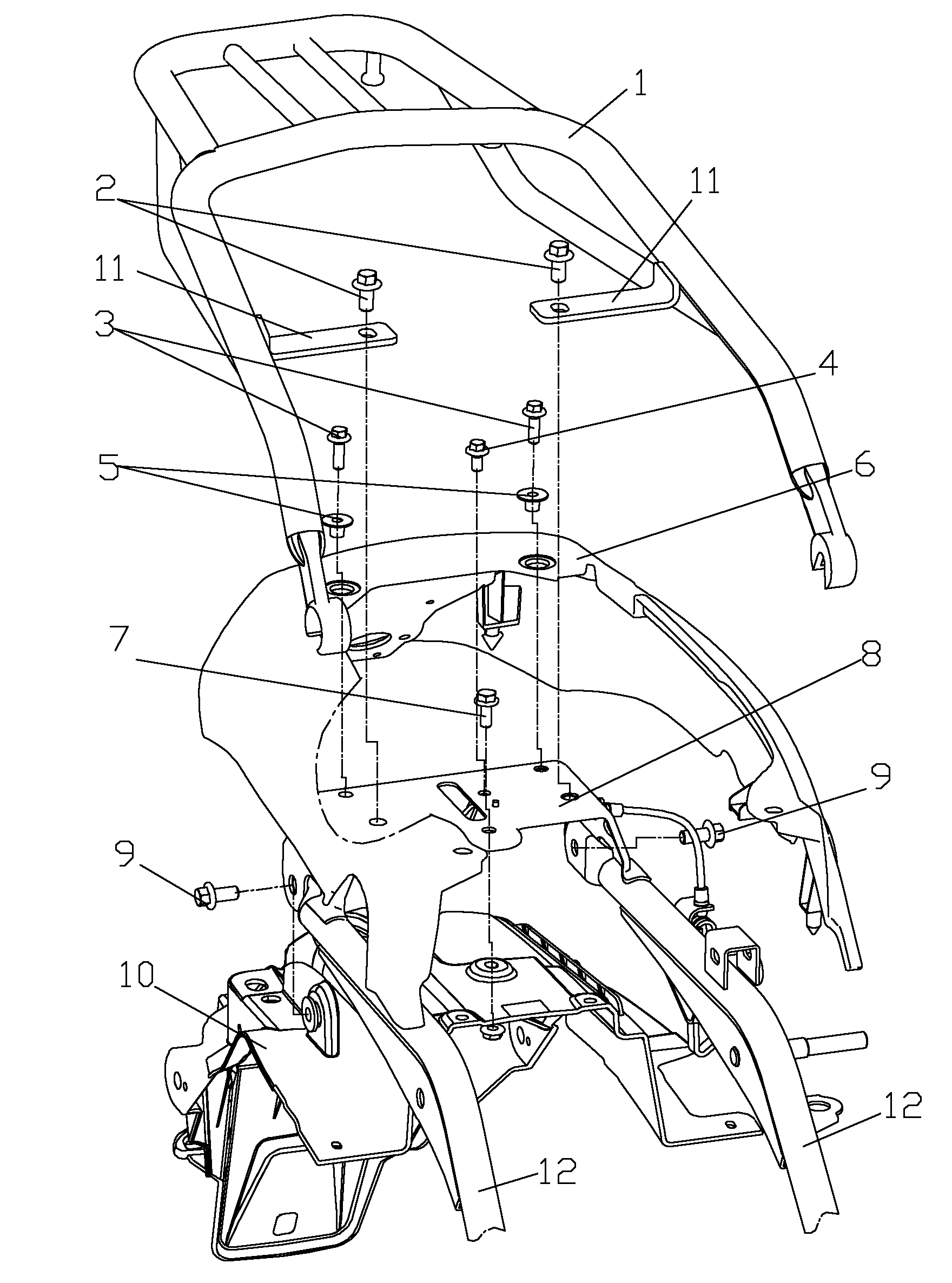

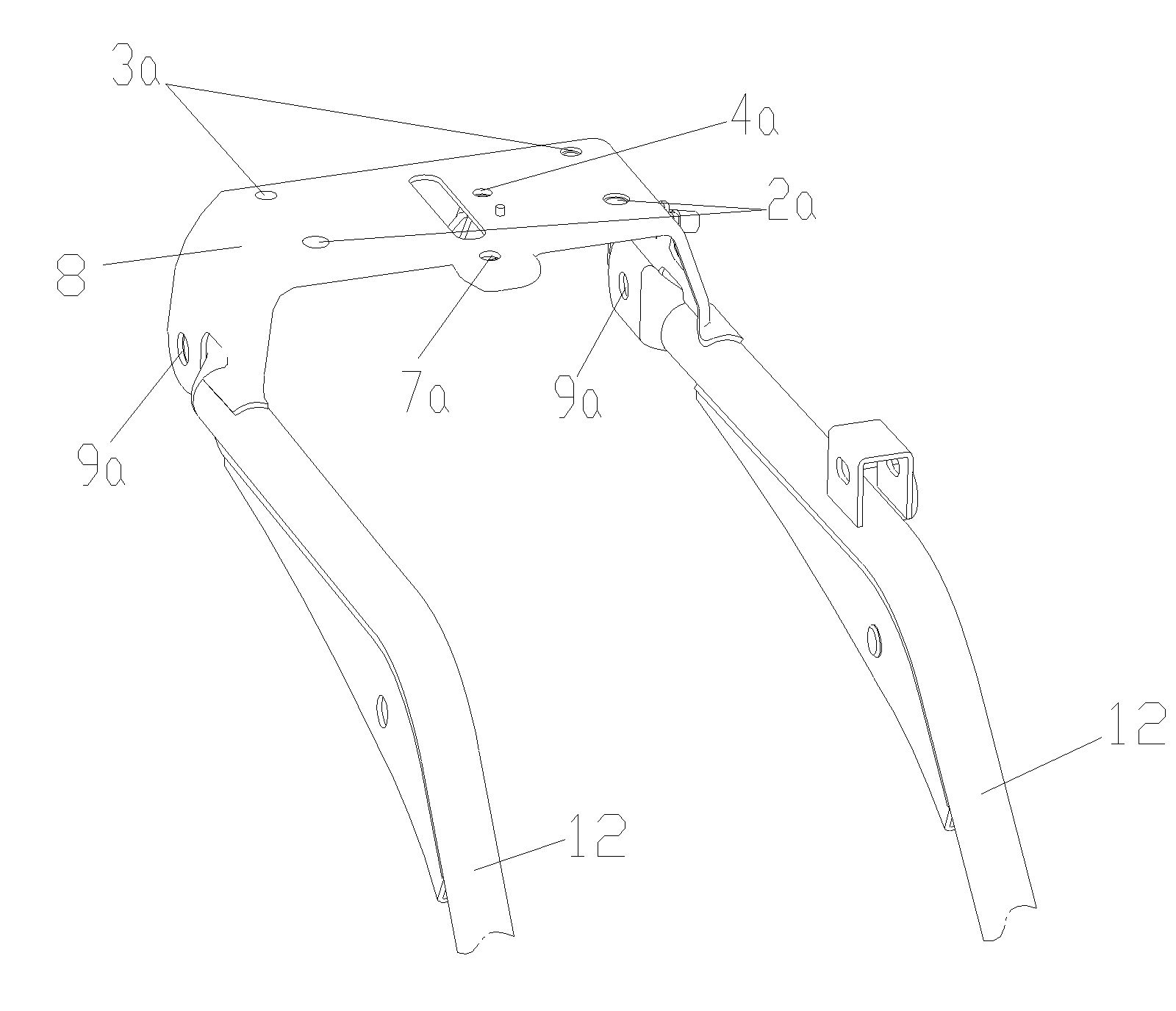

Motorcycle and after-frame assembly thereof

ActiveCN102180212BImproved ability to resist bending momentsImprove loosenessLuggage carriersMotorcyclesVehicle frameEngineering

The invention discloses a motorcycle and an after-frame assembly thereof. The after-frame assembly of the motorcycle comprises a seat cushion loctal base, a rear fender board, a rear carrying rack, a tail cover, frame tail pipes and a connecting plate, wherein two frame tail pipes are parallel along a transverse direction; the connecting plate is laid between the two frame tail pipes and fixedly connected with the two frame tail pipes; and the seat cushion loctal base, the rear fender board, the rear carrying rack and the tail cover are all detachably and fixedly connected with the connectingplate. The after-frame assembly disclosed by the invention realizes the standardized installation of the seat cushion loctal base, the rear fender board, the rear carrying rack and the tail cover, isbeneficial to ensuring the assembling gaps among parts and the installation dimensions among the parts and preventing the interference among the parts and has the characteristics of standardization and high generality; in addition, the after-frame assembly disclosed by the invention has larger size relative to the prior art by adopting a connecting piece structure and has good firmness without deforming the connecting piece when used for a long time, thereby ensuring the integral appearance of the motorcycle.

Owner:CHONGQING LONCIN MOTOR

A production process of aluminum alloy window profiles

ActiveCN110665986BEffective straighteningAccurate flatnessShaping toolsExtrusion control devicesIngotWater cooling

Owner:无锡辰浩建筑节能科技有限公司

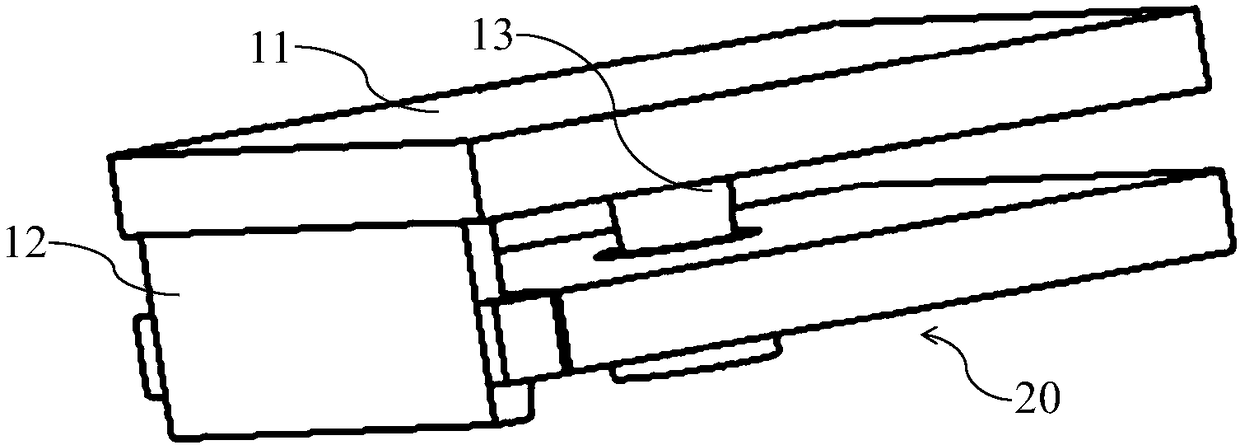

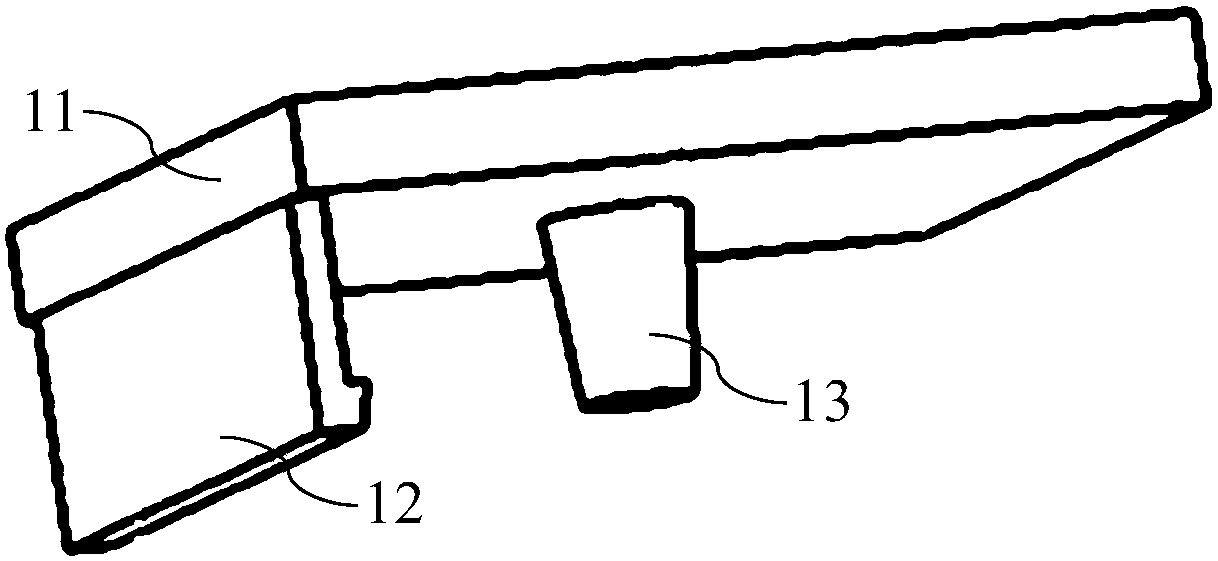

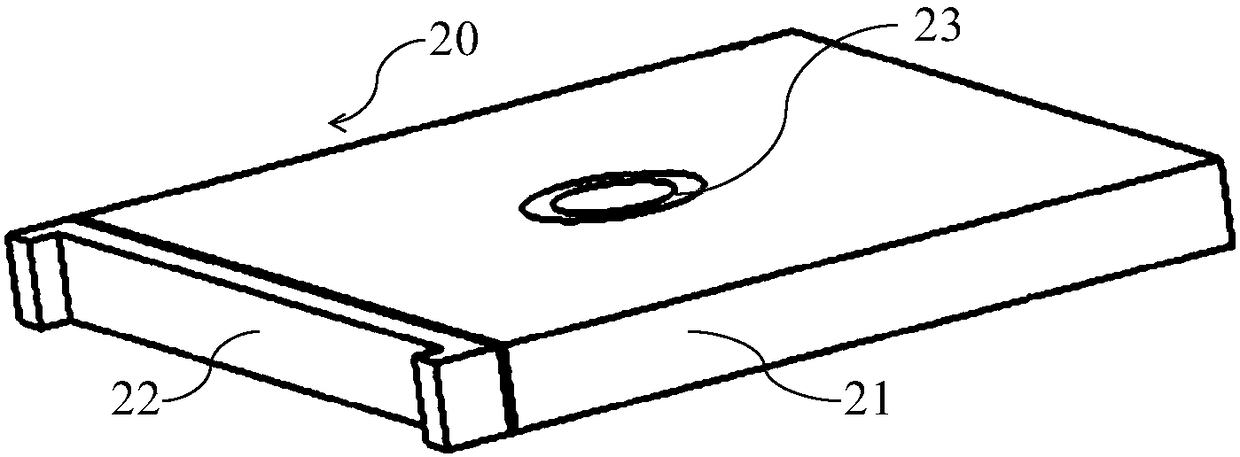

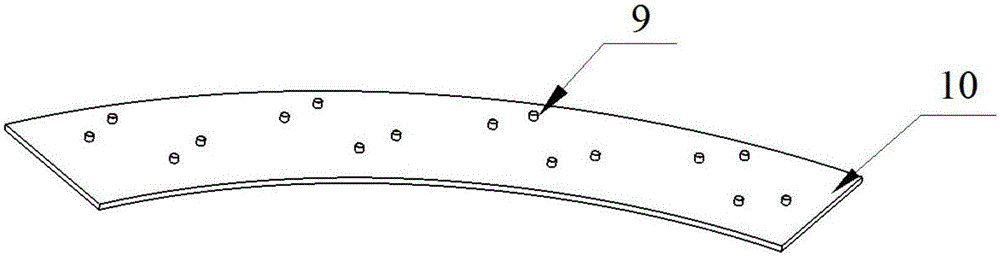

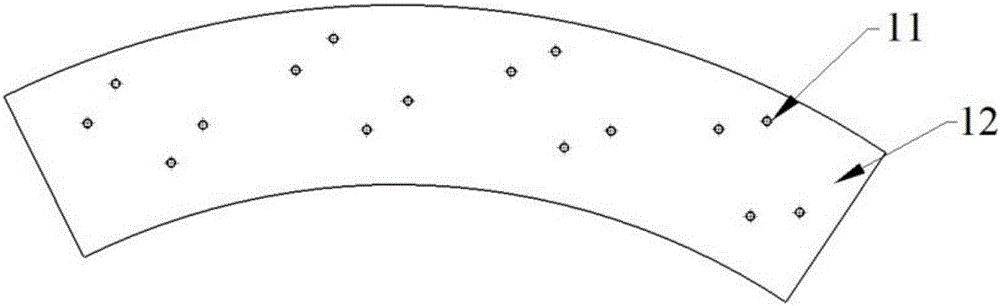

Skin structure and skin installation and detachment methods

ActiveCN108177758AQuick installationQuick releaseFuselage bulkheadsAircraft assemblySkin structureBiomedical engineering

The invention belongs to the technical field of aerospace and particularly relates to a skin structure and a connecting method. The skin structure comprises skin boards, buckles and locating pieces. The locating pieces are fixedly arranged on the skin boards and can be matched with fixing devices on to-be-connected pieces, so that the skin boards are fixed to the relative positions of the to-be-connected pieces. Each buckle is fixedly arranged at one end of the corresponding skin board, the buckles are provided with openings capable of being connected with the end faces of the to-be-connectedpieces in a matched mode, and the openings in the buckles are matched with the end faces of the to-be-connected pieces so that the skin boards can be fixedly connected to the to-be-connected pieces. By the adoption of the skin structure and skin installation and detachment methods, the skin installation and detachment processes can be quickly finished, the connected structure is more stable and reliable, seamless connection can be achieved, and the installation size is guaranteed.

Owner:北京天恒长鹰科技股份有限公司

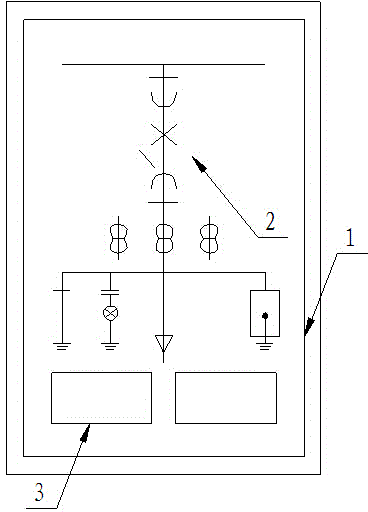

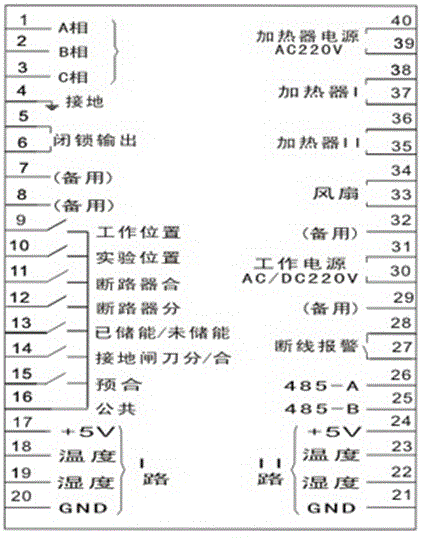

Intelligent operation and control device for switch cabinet

InactiveCN104064981AReasonable structural designCompact layoutSupervisory desks/panelsEngineeringSwitchgear

The invention relates to an intelligent operation and control device for a switch cabinet. The intelligent operation and control device comprises a control display panel, and a dynamic display region for dynamically simulating the state of the operation and control device is arranged on the control display panel. The control display panel is further provided with a plurality of external device physical connecting lines and instant communication line outlets. According to the intelligent operation and control device, a plurality of conventional control modules are displayed on a control panel in a centralized way, dynamic simulation is adopted, vivid display is realized, operation and control errors are avoided, the difficulty in acquiring the same signal by a plurality of modules is eliminated, and the mounting size is ensured on a switch cabinet panel. The intelligent operation and control device has the advantages of reasonable structural design, compact layout, complete functions, convenience in use, stable and reliable performance, convenience in subsequent use and maintenance and meeting of the practical use requirements.

Owner:合肥鑫伟电力设备有限公司

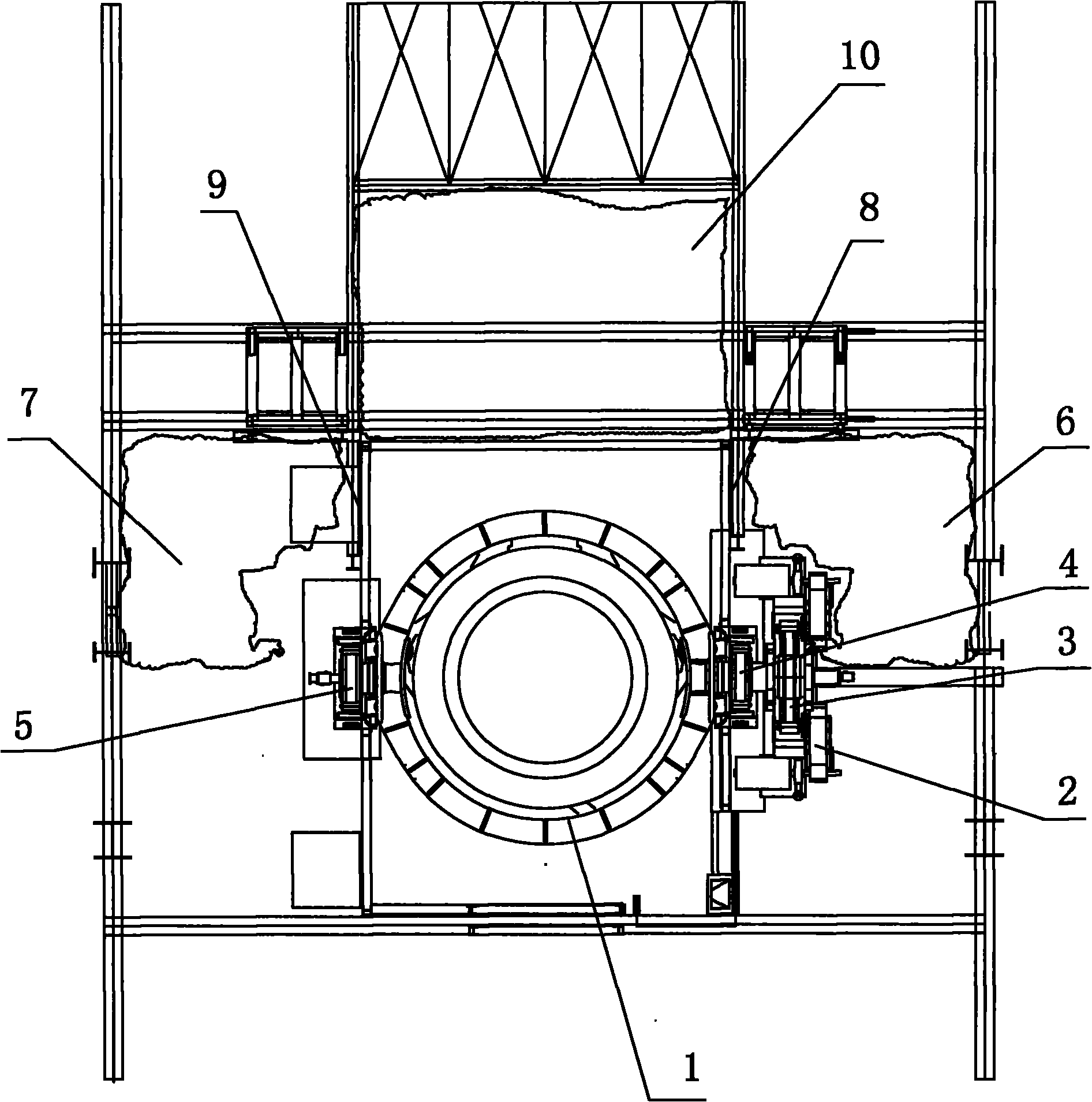

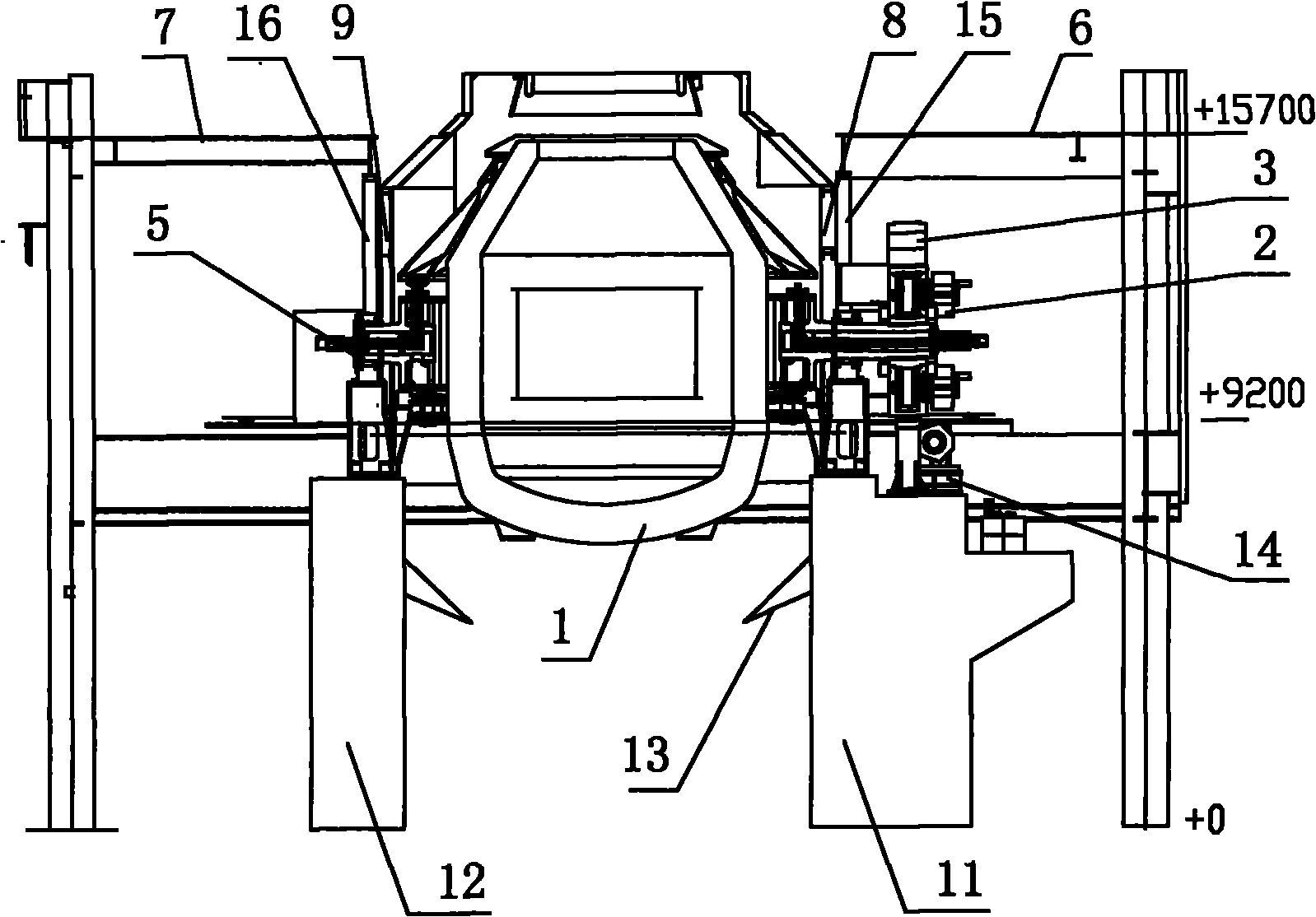

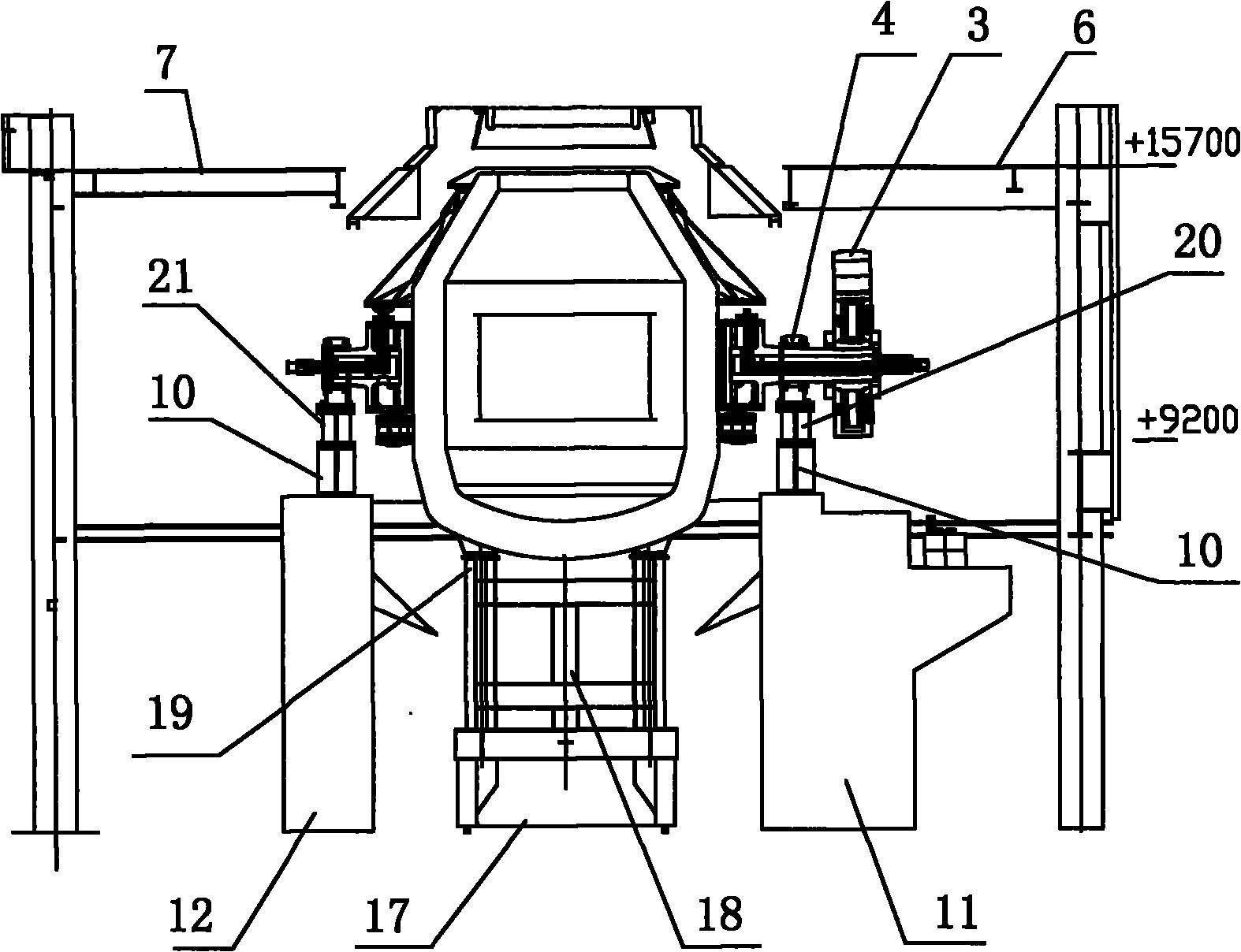

Method for replacing rotating furnace

InactiveCN101638705BReduce construction difficultyShorten the construction periodManufacturing convertersReducerEngineering

The invention relates to a method for replacing a rotating furnace, which is characterized by comprising the following steps: 1) carrying out assembling to a new rotating furnace in a span in which travelling cranes for lifting are located; 2) fixing a carrying stand on a ladle car, and fixedly arranging four hydraulic jacks on the carrying stand; then running the ladle car to the lower part of the furnace body of the old rotating furnace, lifting the four hydraulic jacks, supporting four supporting legs at the bottom part of the furnace body of the old rotating furnace on the corresponding four hydraulic jacks; 3) removing a torsion rod and a primary speed reducer of the old rotating furnace and removing the barriers in the span in which the travelling cranes are located and at the frontof running for removing the old rotating furnace; 4) running the ladle car and leading the old rotating furnace to separate from the original installing position; and 5) moving two travelling cranes and lifting a new rotating furnace to the installing position; and installing the primary speed reducer and the torsion rod of the new rotating furnace. The method is characterized by having fast construction speed, saving cost and reducing potential safety hazard.

Owner:CHINA FIRST METALLURGICAL GROUP

Bed body structure of Raschel loom

InactiveCN105442175AUniform structure distributionReliable weldingWarp knittingElectric machineryFuel tank

The invention relates to a bed body structure of a Raschel loom. The bed body structure comprises a bed main body. A first oil tank structure, a second oil tank structure, a sand tank structure, a machine frame supporting structure, a guide bar transverse movement supporting structure, a hydraulic element installing structure and a main motor base installing structure are arranged on the bed main body. The machine frame supporting structure is located at the lathe head, the lathe middle and the lathe tail of the bed main body. The main motor base installing structure is located on the back face of the bed main body. The first oil tank structure is located at the upper portion of the bed main body. The sand tank structure is located below the first oil tank structure. The second oil tank structure, the guide bar transverse movement supporting structure and the hydraulic element installing structure are located at the lathe head of the bed main body. The bed body structure is uniform in structure distribution, firm in welding and high in overall strength and rigidity; meanwhile, various installation positions of other parts of a main machine are prefabricated, and the installation size is ensured.

Owner:ZHEJIANG YUEJIAN INTELLIGENT EQUIP CO LTD

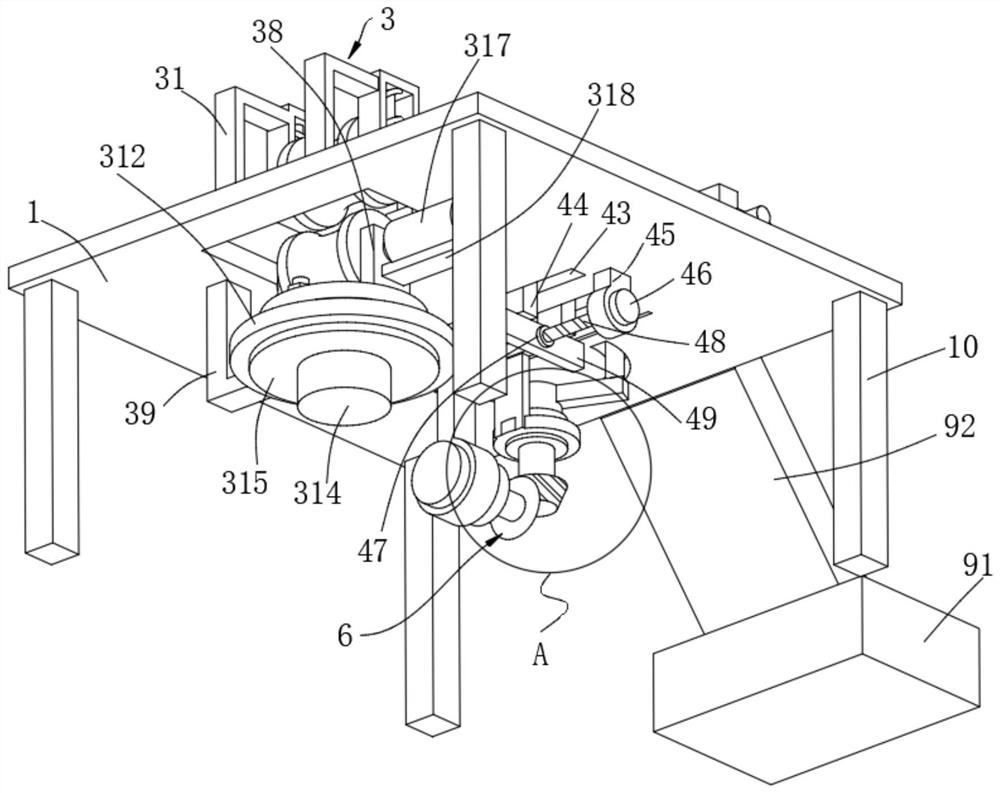

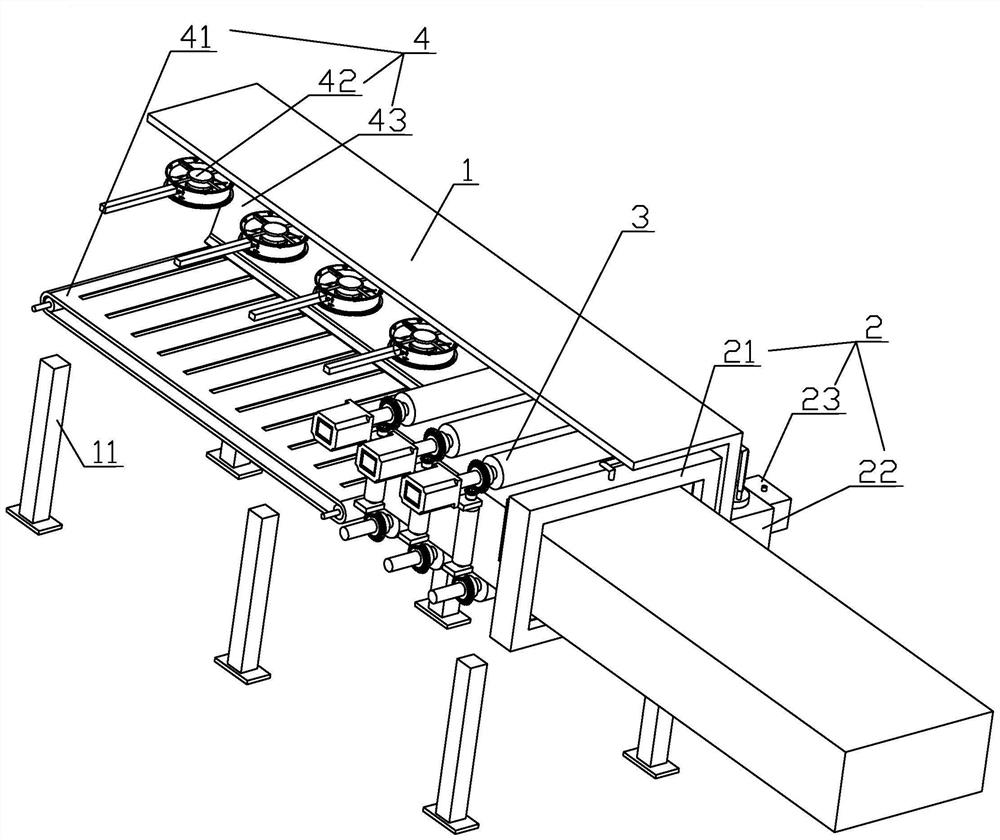

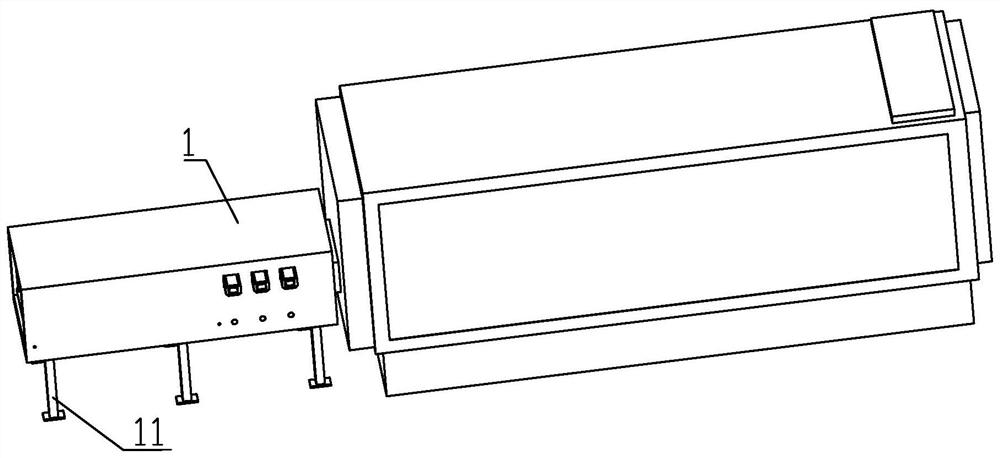

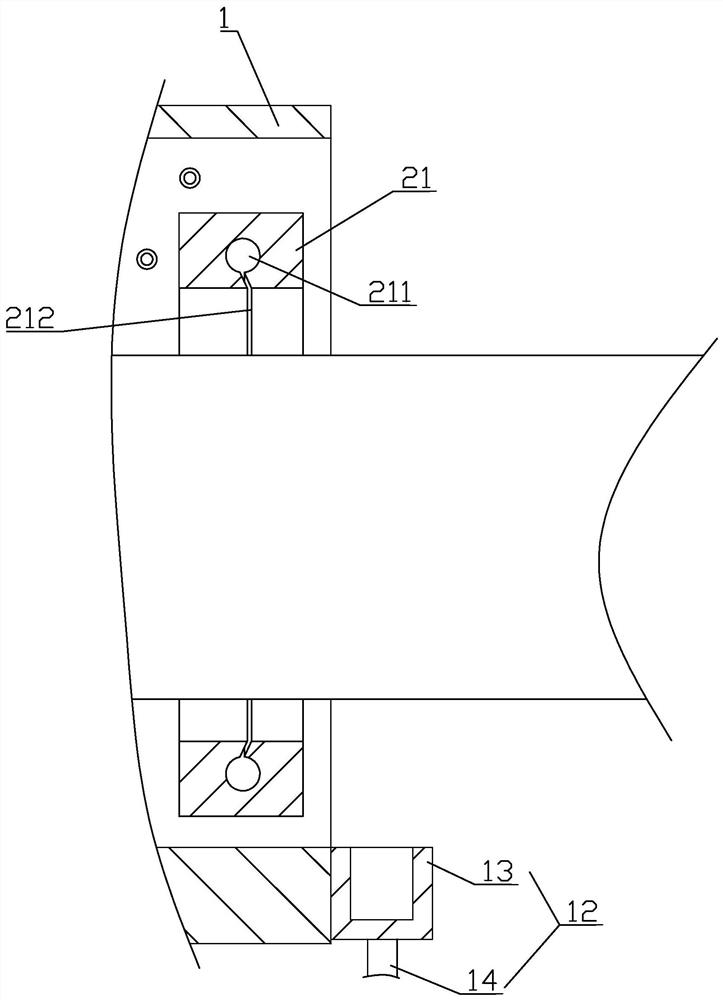

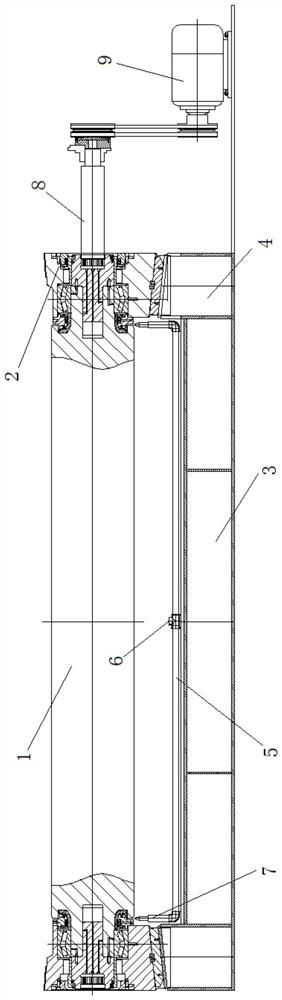

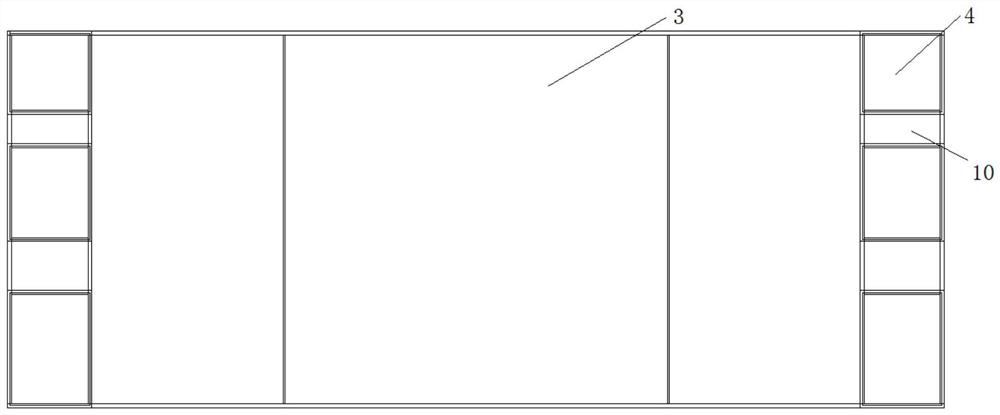

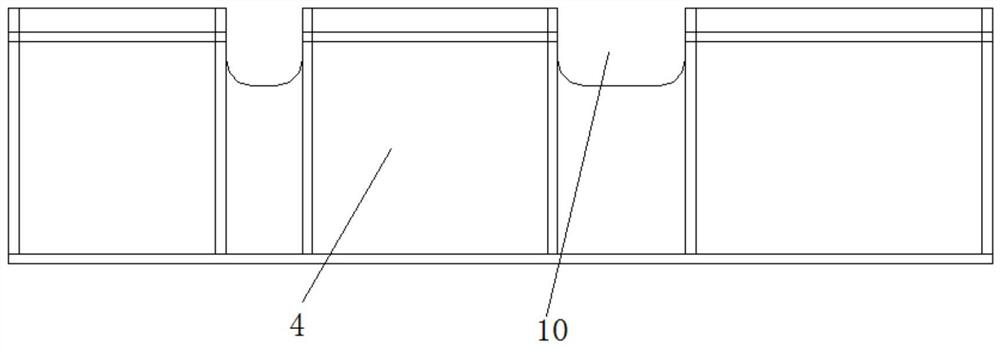

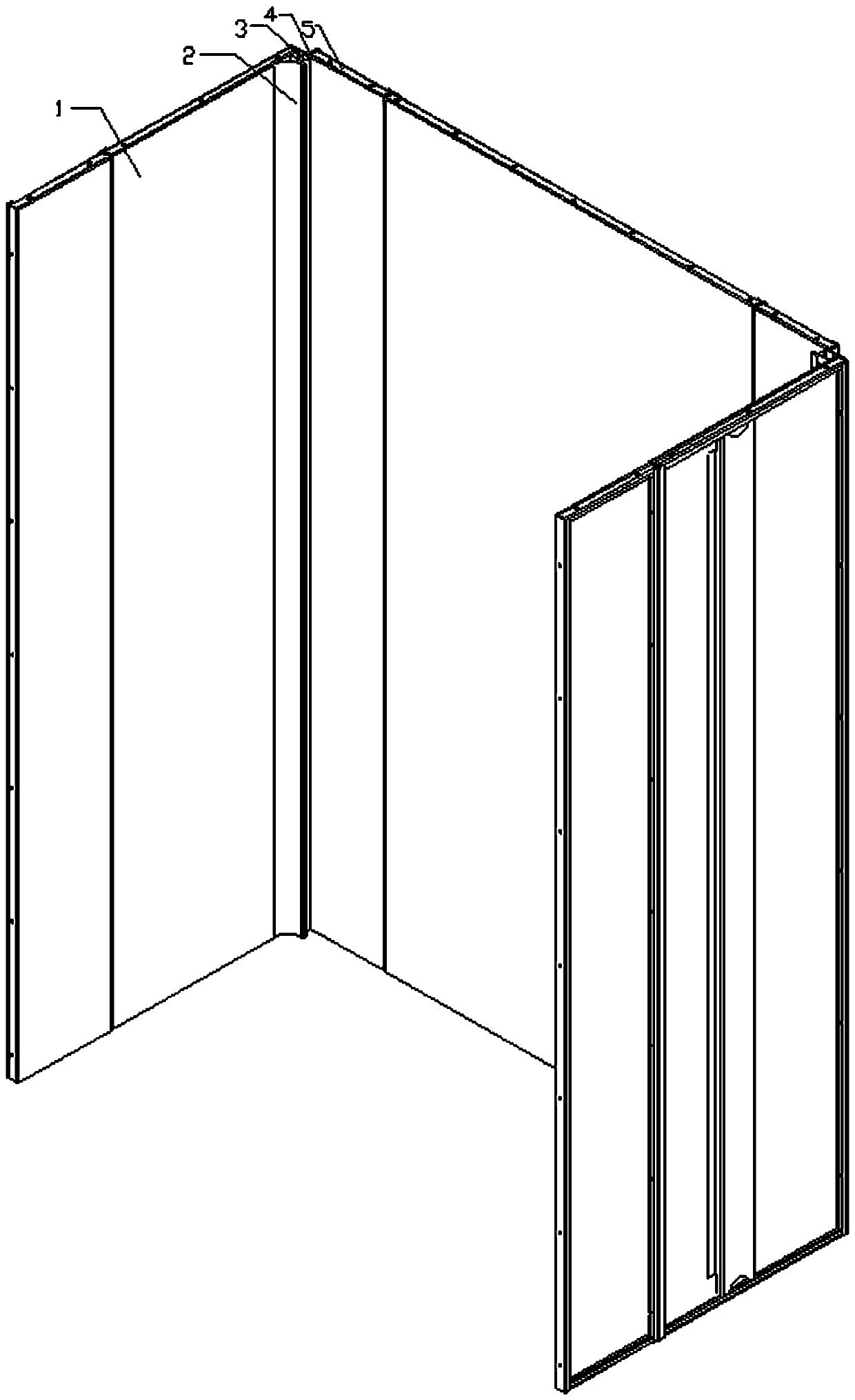

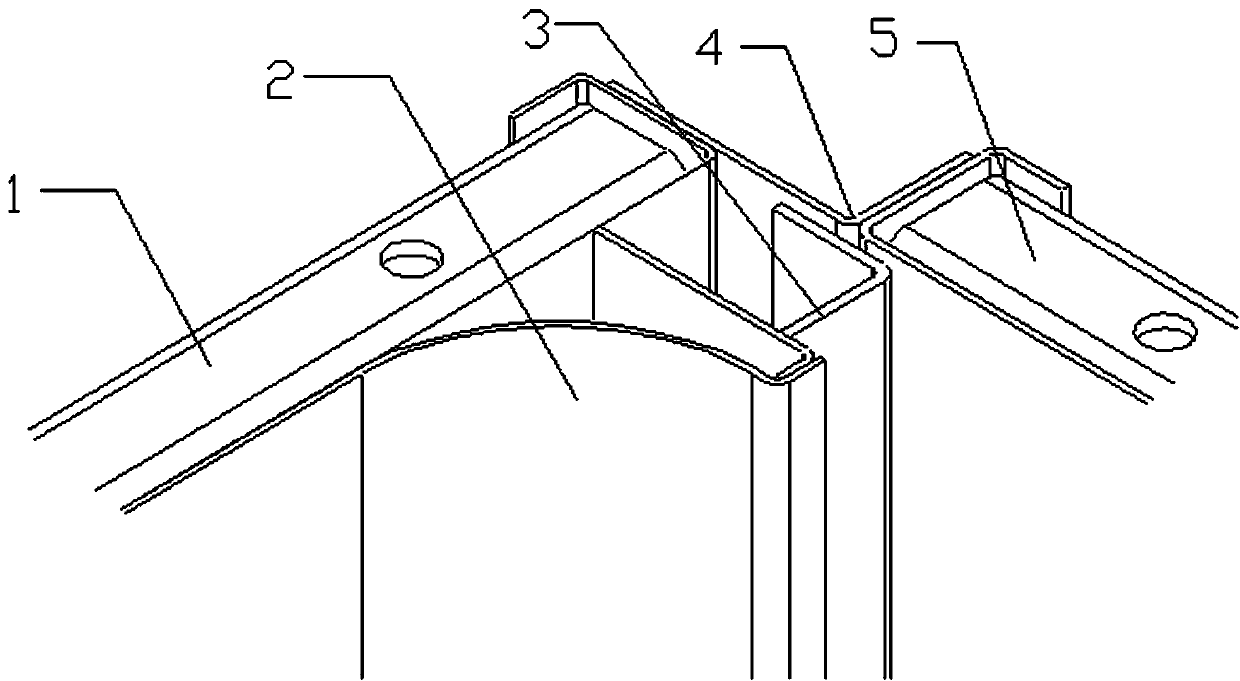

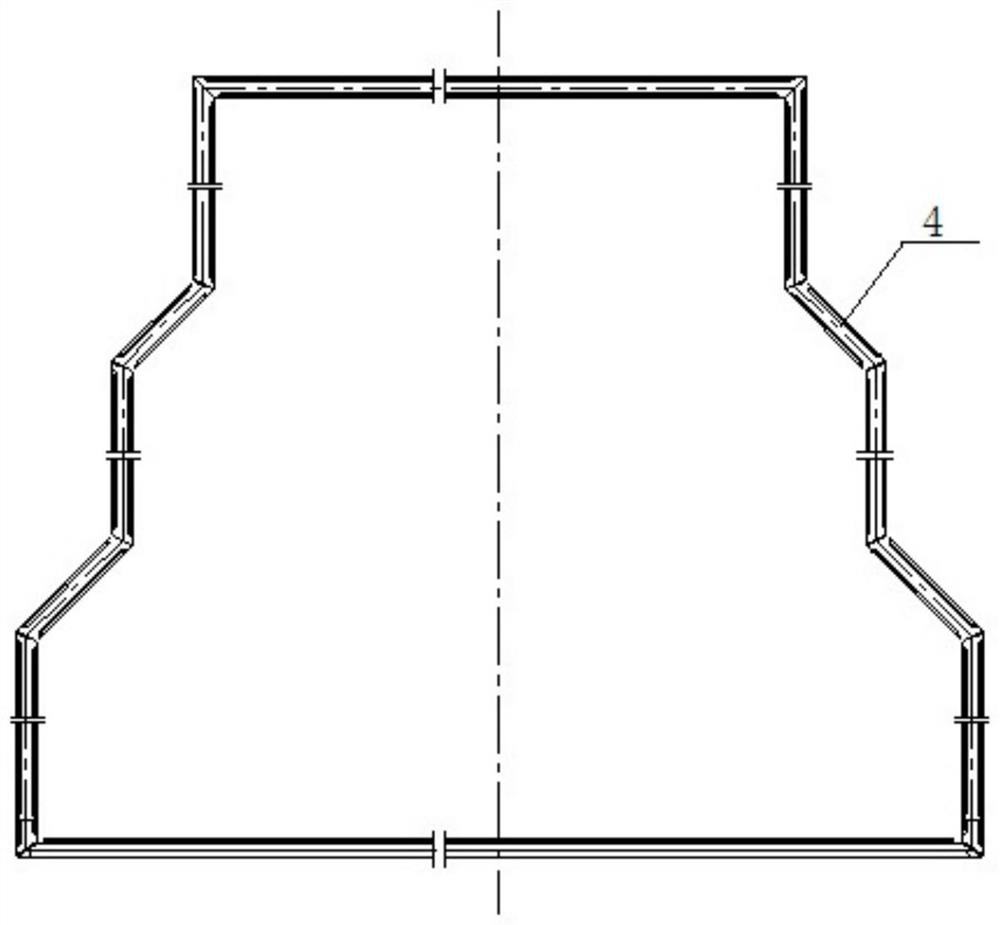

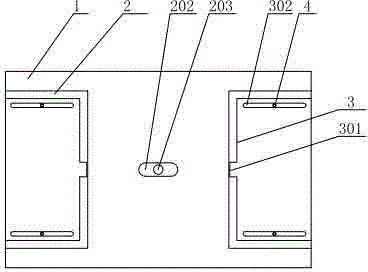

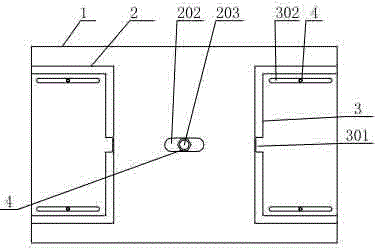

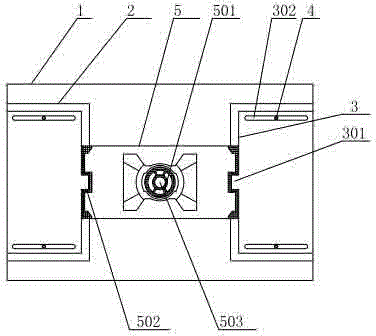

A kind of track crane installation method

ActiveCN107673202BLower requirementGuaranteed installation sizeTravelling gearRunwaysEngineeringGantry crane

The invention relates to a rail-mounted gantry crane installing method, and belongs to the technical field of rail-mounted gantry crane installation. The method comprises the steps of cart walking mechanism arranging, lower beam installation, landing leg installation and main beam arranging. Carding and optimizing are conducted on details of the false flange form rail-mounted gantry crane generalassembly process, the installing size is ensured, aerial work is reduced as much as possible, the requirement for installation of auxiliary equipment is lowered, and the method is applicable to various inland freight transport fields.

Owner:WUXI HUADONG HEAVY MACHINERY

Bracket for fixing condenser on intercooler and intercooler core body

PendingCN107939508AReduce welding processIncrease productivityInternal combustion piston enginesIntercoolerWelding

The invention discloses a bracket for fixing a condenser on an intercooler and an intercooler core body, belongs to the technical field of vehicle-mounted heat dissipation, and solves the technical problems of complicated manufacturing process, time and force waste and lower assembly precision and production efficiency in the prior art. The bracket for fixing the condenser on the intercooler comprises the bracket and the intercooler core body, wherein the bracket is provided with a thread hole; the intercooler core body comprises a core body protection plate; and the bracket is welded on the core body protection plate. Through the device structure, one welding procedure is saved, both time and labor are saved, the mounting size of the condenser can be guaranteed, and the production efficiency is improved.

Owner:SHANDONG TONGCHUANG AUTO COOLING SYST

Carbon fiber bicycle disc brake base and its forming process

ActiveCN104552927BGuaranteed installation sizeRealize one-piece moldingCycle brakesFiberCarbon fibers

The invention discloses a carbon fiber bicycle disc brake substrate and a molding process thereof. Processed cylindrical nuts with threads are embedded in two protruding legs of a prefabricated carbon fiber substrate; the substrate is placed in a mold, the cylindrical nuts are locked by screws and are fixed in a positioning mold cavity of the mold; the mold is closed and the substrate is molded; the mold is opened, the carbon fiber bicycle disc brake substrate is taken out, and the screws are unfastened, and thus the production of the integrated disc brake substrate is completed. The cylindrical nuts are embedded in the carbon fiber bicycle disc brake substrate, and are fixed by the screws, so that the carbon fiber bicycle disc brake substrate and the cylindrical nuts are integrally molded, and are excellently combined by utilizing the carbon fiber material characteristics; through the setprecision of the cylindrical nuts, the mounting size of a disc brake is ensured and the secondary processing steps are omitted; in addition, by the integrated molding mode, the damage to carbon fibers can be avoided, and the strength and the life of the disc brake substrate are effectively ensured.

Owner:上海迪诺克新材料科技有限公司

A countersunk hole processing method of wear-resistant liner

The invention discloses a counterbore processing method for a wear-resisting lining plate. The counterbore processing method for the wear-resisting lining plate is characterized by including steps that a, setting out and blanking; b, tapping and profiling; c, machining a counterbore workpiece; d, welding the counterbore workpiece and drilling an outer bore sleeve. The counterbore processing method for the wear-resisting lining plate has advantages that the manufacturing step design is reasonable, the operation is easy to perform, the wear-resisting lining plate is processed easily and effectively, the mounting size is guaranteed, and the processing cost is greatly lowered.

Owner:MCC5 GROUP CORP SHANGHAI

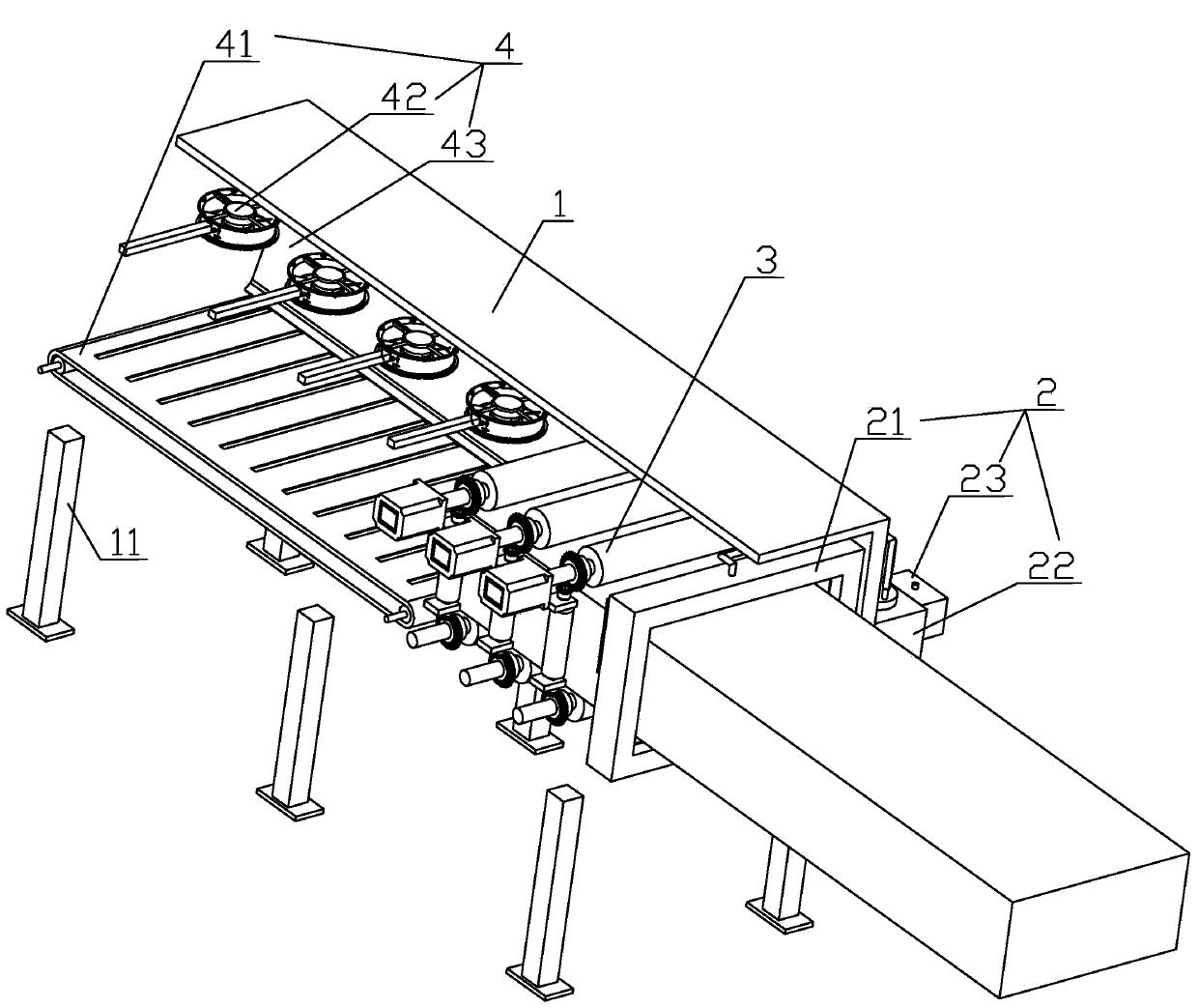

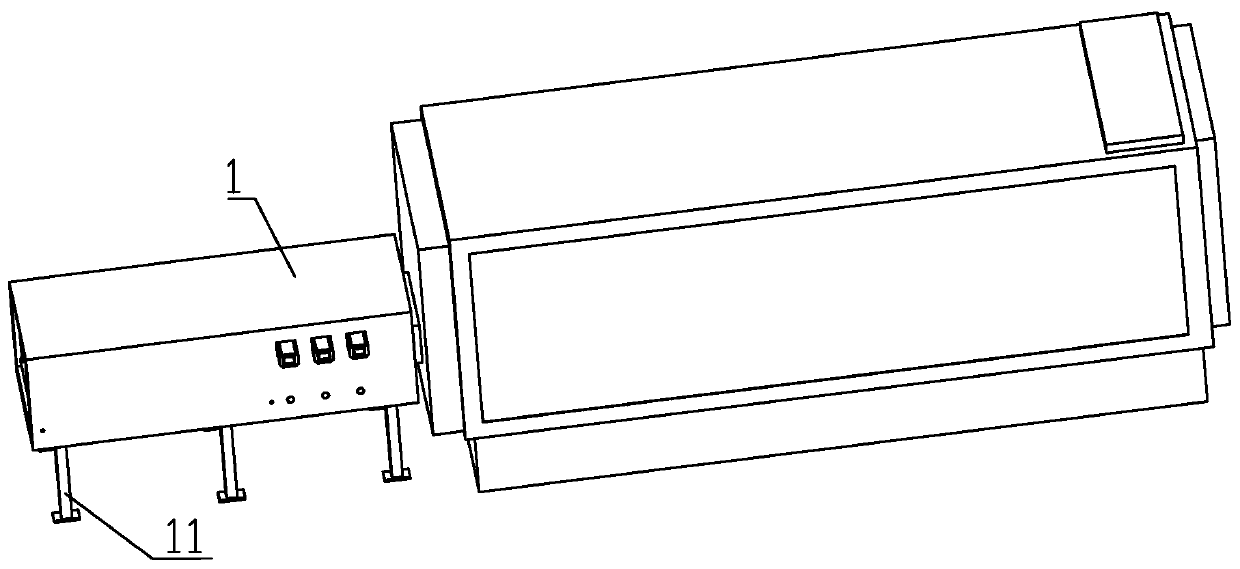

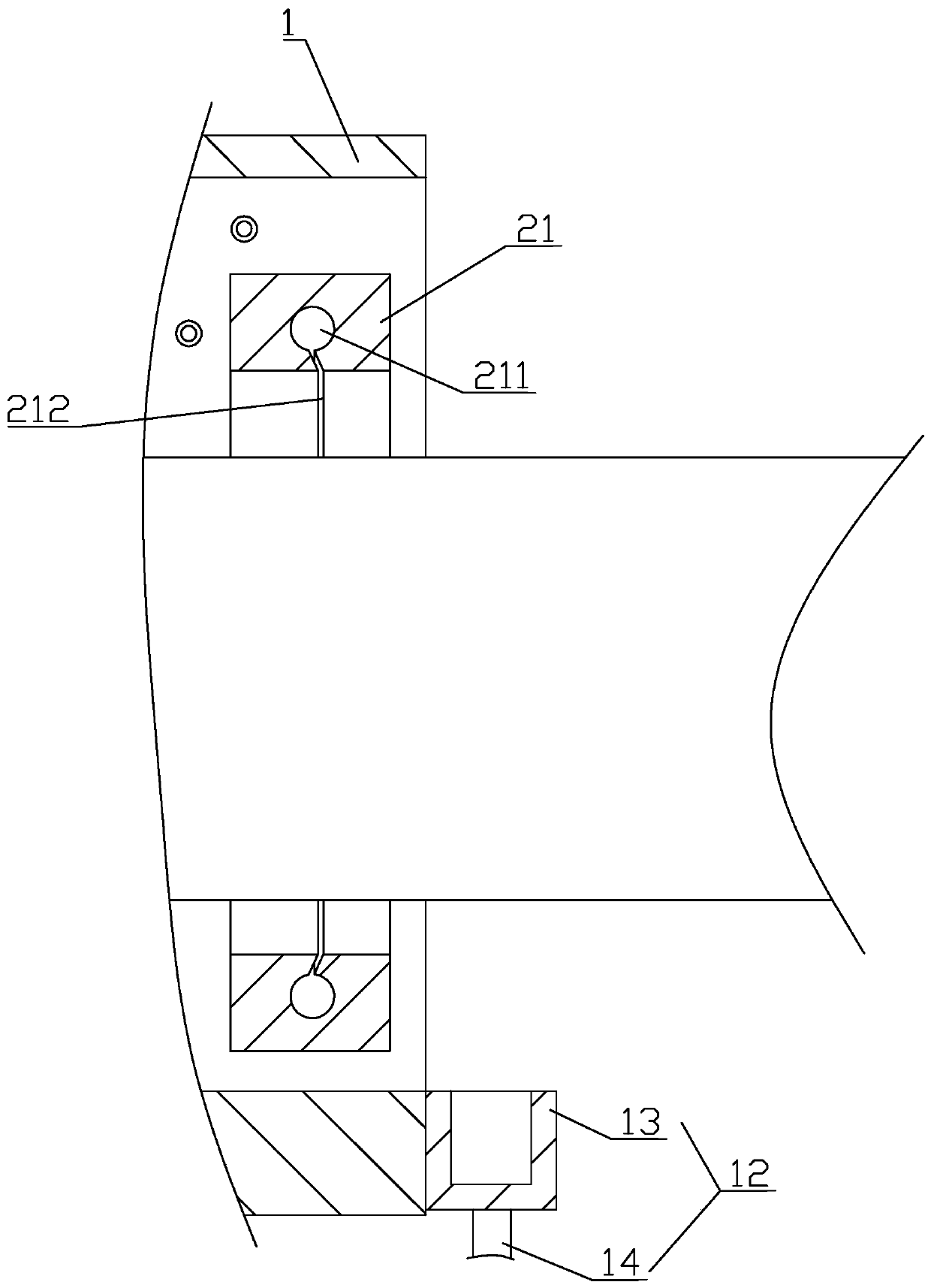

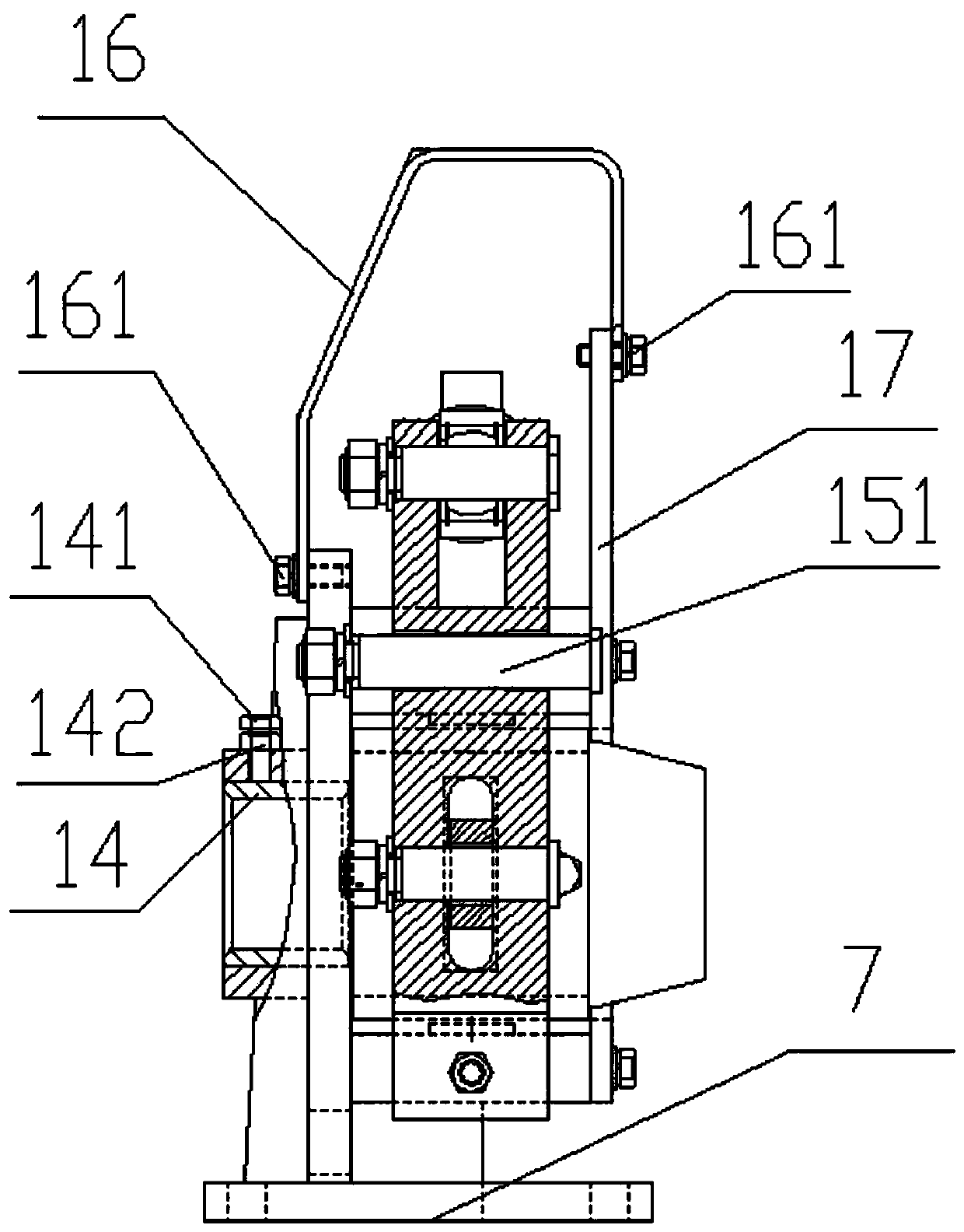

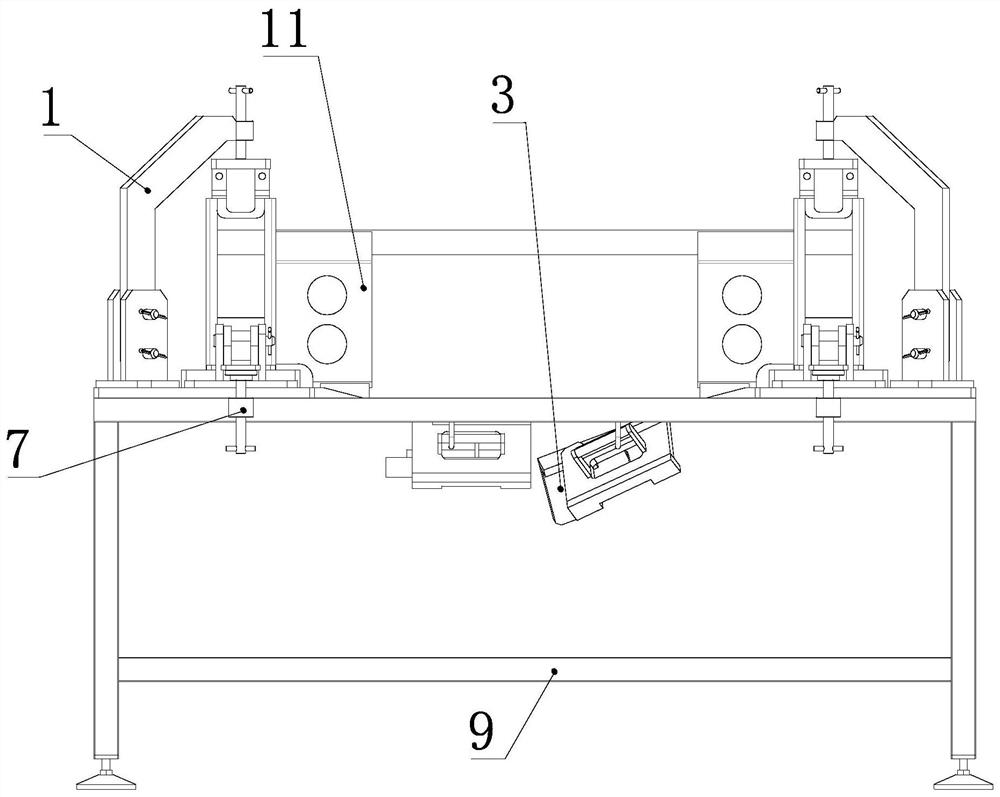

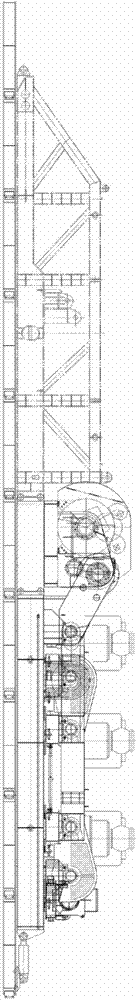

Thick plate line rolling mill stand roller test run device and detection method

PendingCN113532847ARepair test acceptance guaranteeExtended service lifeMachine gearing/transmission testingThick plateStructural engineering

The invention belongs to the technical field of machinery, and relates to a thick plate line rolling mill stand roller test run device and a detection method, the thick plate line rolling mill stand roller test run device comprises a test run tool platform and a stand roller assembly fixedly installed on the test run tool platform, and the stand roller assembly comprises a stand roller body and bearing seats arranged at the two ends of the stand roller body in a matched mode; and the test run tool platform comprises an installation platform and fixed bases fixed to the two ends of the installation platform respectively, and the fixed bases are higher than the installation platform and fixedly attached to the bottoms of the rack roller assembly bearing seats. The test run tool platform is used for performing test run detection on the rack roller, so that the repair test run acceptance of the rack roller is guaranteed, and the repair quality is improved; and the device can simulate the production working condition to detect the forward and reverse rotation of the rack roller, and detect the conditions of axial movement, abnormal sound, sealing performance, bearing heating and the like, can guarantee the installation size, effectively prolongs the service life of rack roller equipment, reduces the repair cost, and improves the production efficiency.

Owner:CHONGQING IRON & STEEL CO LTD

Arc car wall structure

InactiveCN107804769AGuaranteed installation sizeEasy to disassembleBuilding liftsEngineeringCorner angle

Owner:苏州银海机电科技有限公司

A positioning method for rubber groove brackets used for stern ramps of large ships

ActiveCN110341880BGuaranteed installation sizeGuaranteed installation qualityVessel designingMarine engineeringStructural engineering

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Mounting method for movable magnetic head in financial payment and used unit

ActiveCN100371991CGuaranteed installation sizeSatisfy thinning requirementsDisposition/mounting of recording headsSensing record carriersPaymentStructural engineering

A method for installing active magnetic head in financial payment device includes setting a removable plate used to install magnetic head on said device, setting two holes corresponding to erection holes on magnetic head on removable plate, setting cylindrical body on said holes, passing said erection holes through top end to middle part of cylindrical body and spacing bottom of said erection holes at middle part of cylindrical body, setting top spacing mechanism at top end of cylindrical body to let erection holes of magnetic head be able to move between two said spacing.

Owner:SHENZHEN ZHENGTONG ELECTRONICS

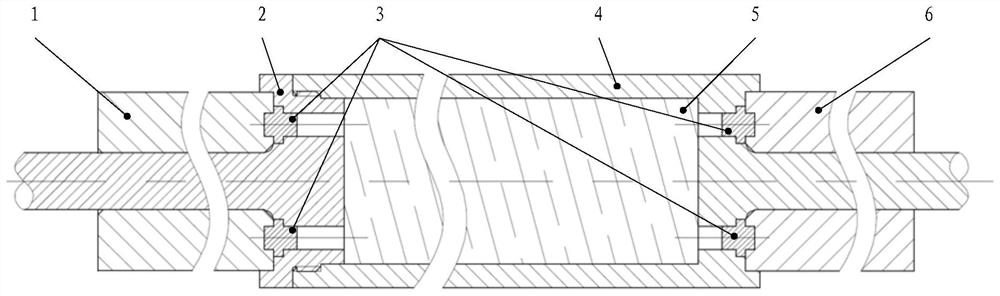

High-speed large-torque motor rotor structure and process of thermoelectric conversion system

ActiveCN112350506AImprove assembly accuracyIncrease stiffnessMagnetic circuit rotating partsPump componentsElectric machineTorque motor

The invention relates to a high-speed large-torque motor rotor structure and process of a thermoelectric conversion system. The structure comprises an end cover shaft sleeve, an end cover shaft, a stop element, a sheath shaft, a magnetic core and a sheath shaft sleeve. On the basis of determining the size parameters of the end cover shaft sleeve, the end cover shaft, the stop element, the sheath shaft, the magnetic core and the sheath shaft sleeve, the processing of the motor rotor assembly assembling part is completed. Firstly, the end cover shaft, the magnetic core and the sheath shaft are assembled, secondly, the stop element, the end cover shaft and the sheath shaft are assembled, thirdly, the end cover shaft sleeve, the end cover shaft and the stop element are assembled, thirdly, thesheath shaft sleeve, the sheath shaft and the stop element are assembled, and finally, the motor rotor is integrally machined. The motor rotor has the characteristics of simple structure, good manufacturability, high rigidity, large transmission torque and the like, and the power density and the working reliability of the motor can be effectively improved.

Owner:BEIJING POWER MACHINERY INST

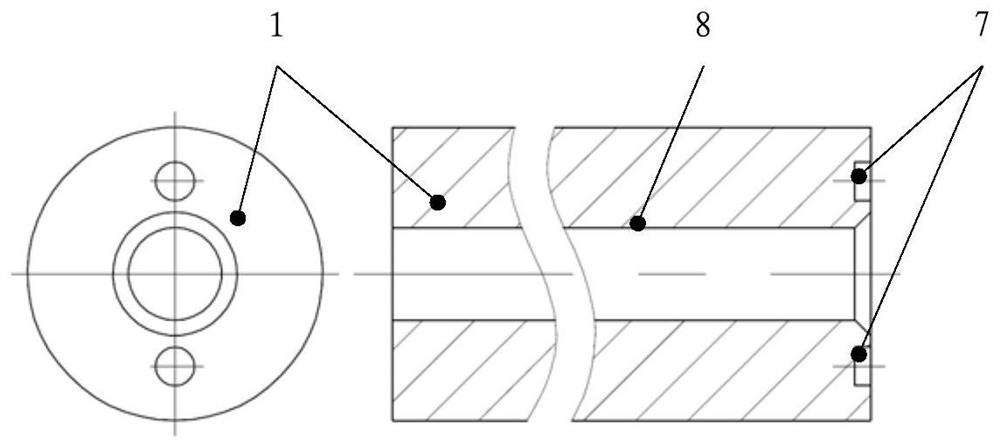

A tooling structure for three-phase inductance coil combination

ActiveCN103474227BRealize combined installationGuaranteed DimensionsCoils manufactureThree-phaseEngineering

The invention relates to a tool structure for a three-phase inductance coil combination. The tool structure for the three-phase inductance coil combination comprises a bottom plate, wherein grooves are symmetrically formed in the bottom plate; mounting supports are fixedly connected to the grooves; a first boss is also arranged on the bottom plate and between the two mounting supports; a plurality of buffering base plates which are arranged at intervals are connected between the two mounting supports in an inserted manner; and space for holding three-phase inductance coils is formed among the buffering base plates. Combination mounting of a plurality of three-phase inductance coils is effectively realized. The tool structure is easy to mount and high in mounting speed; the mounting efficiency is greatly improved; and moreover, the external dimensions and the mounting dimensions of the combined three-phase inductance coils meet the requirement on production.

Owner:WUXI JINGLEI ELECTRONICS

Skin structure and skin installation and disassembly methods

ActiveCN108177758BQuick installationQuick releaseFuselage bulkheadsAircraft assemblySurgerySkin structure

Owner:北京天恒长鹰科技股份有限公司

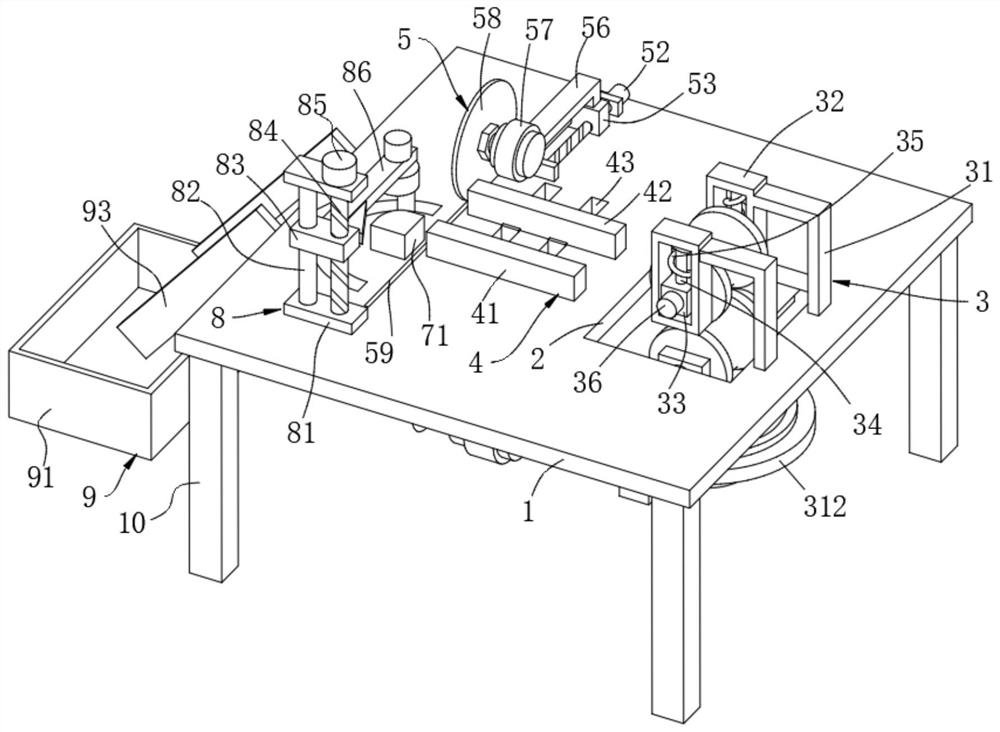

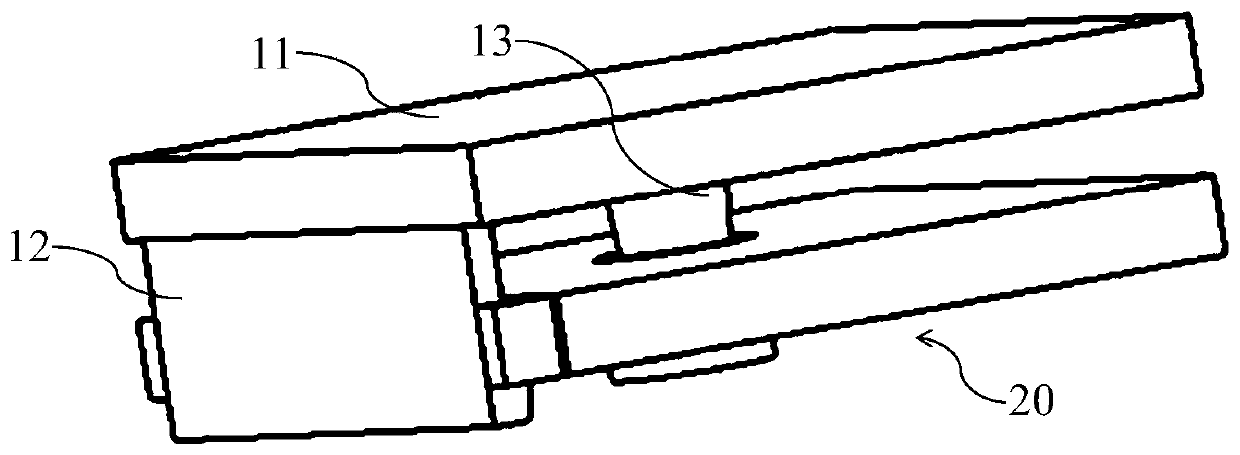

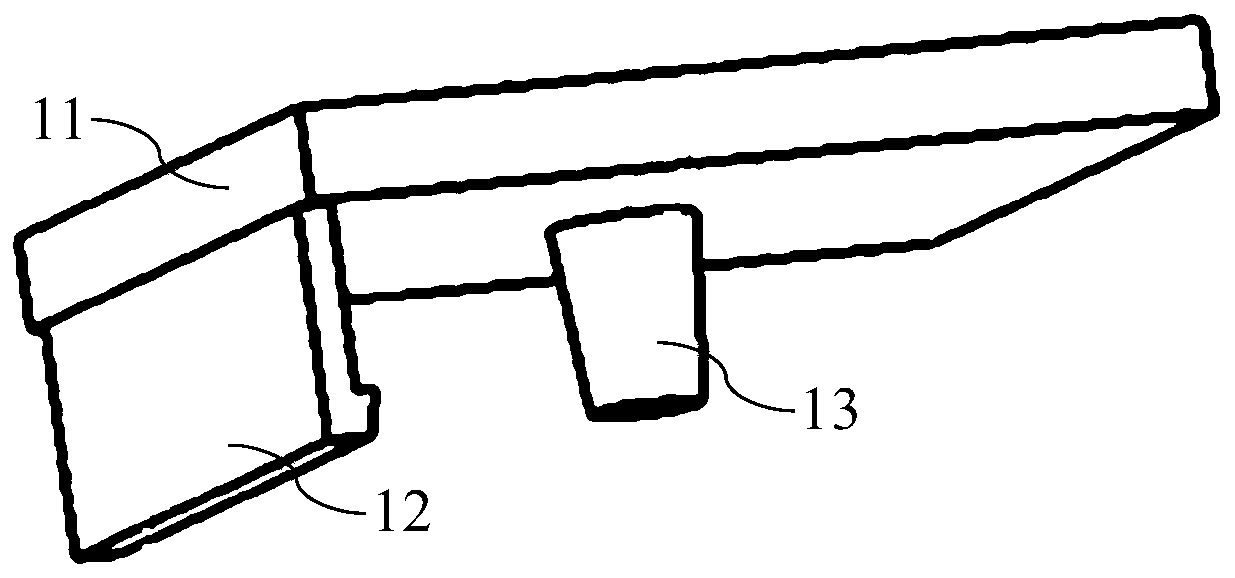

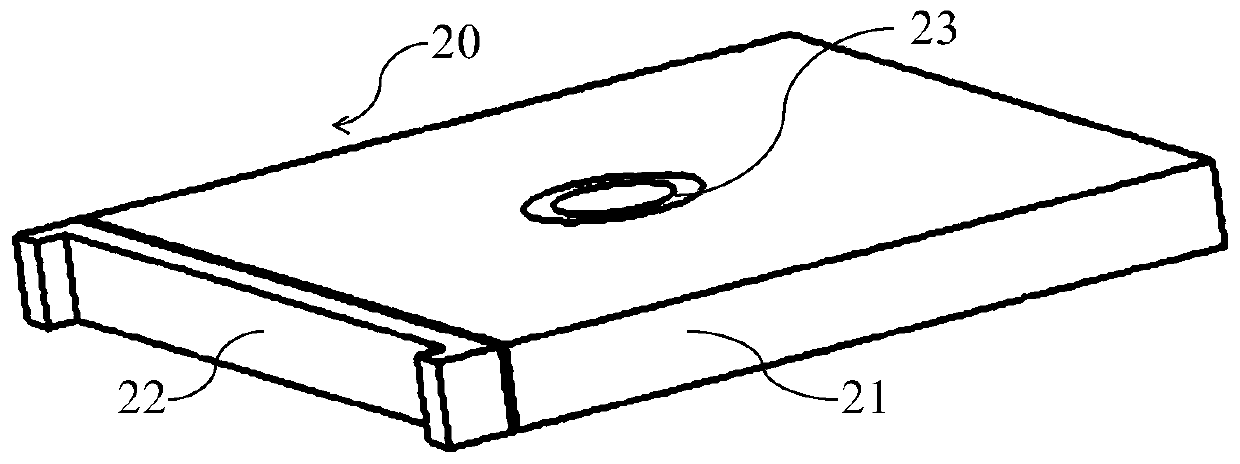

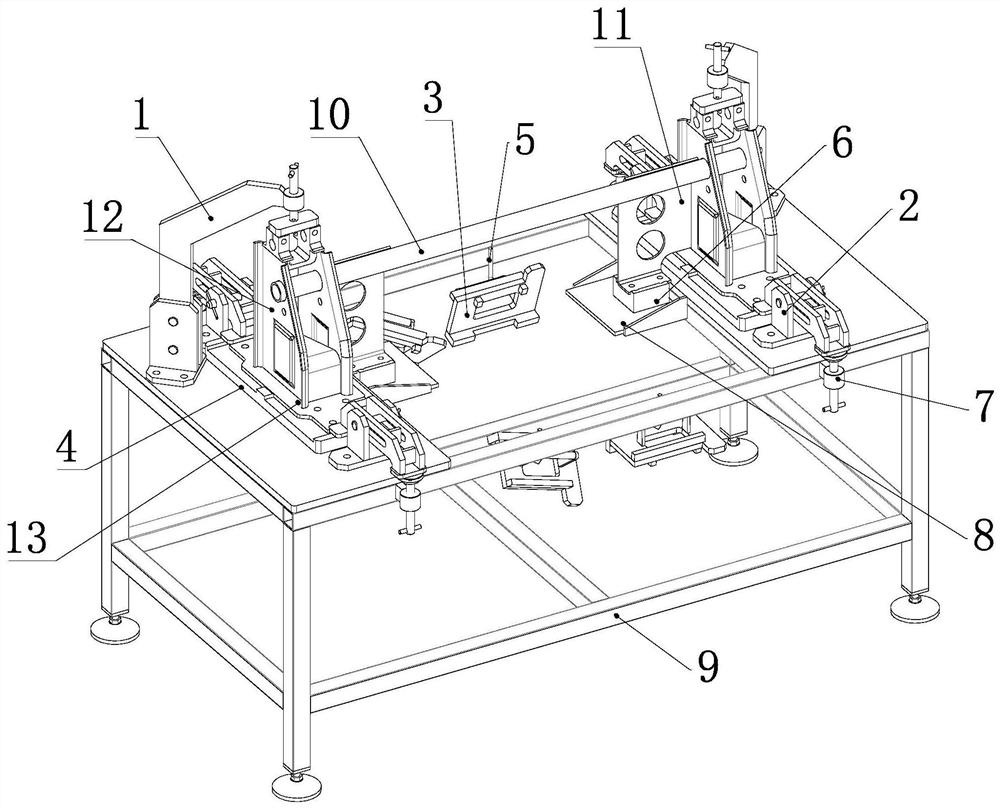

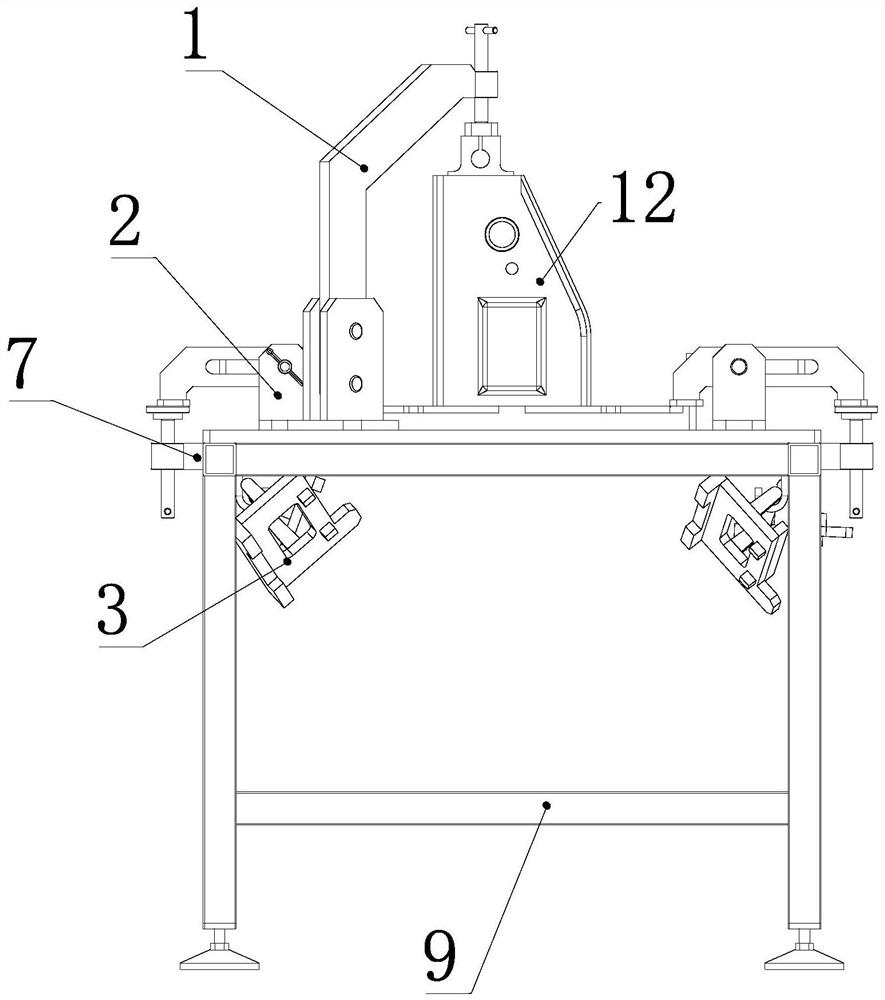

A suspension assembly welding tool and its processing method

ActiveCN109986266BAvoid pairing errorsGuaranteed pair clearanceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPhysics

The invention belongs to the technical field of aluminum alloy welding, and relates to a suspension assembly welding tool and a processing method thereof. The suspension assembly welding tool comprises a suspension welding workbench, connecting plate limiting seats mounted on both sides of the suspension welding workbench, second pressing devices mounted on the front and rear sides of the connecting plate limiting seats, and first pressing devices fixedly mounted on the outer sides of the connecting plate limiting seats; a pair of bracket strengthening plate supports are fixedly mounted on thesuspension welding workbench on the opposite sides of the connecting plate limiting seats; two hooks are fixedly mounted on the suspension welding workbench on both sides of the bracket strengtheningplate supports; bracket assemblies placed on the connecting plate limiting seats; pressing plate assemblies are respectively placed on the front and rear sides of the bracket assemblies; a bracket connecting pipe having bracket strengthening plates fixedly mounted at two ends, is clamped between the bracket assemblies; and limiting blocks for limiting the movement of the bracket strengthening plates are fixedly mounted on the bracket strengthening plate supports. The suspension assembly welding tool is capable of solving the problem that the suspension assemblies are tack welded through riveter grouping in the prior art so that grouping errors are easy to occur and the suspension assembly welding efficiency is low.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

Assembly and welding process of single upper ring type large-scale split seat ring with base plate

The invention relates to an erecting welding technological method for a single-upper-ring type large segmented stand ring with sole plates. A sole plate positioning template and positioning pipes are used for precise positioning; and after splice welding of a lower guide plate, fixed guide vane mounting holes are perforated in a matched mode, and then fixed guide vanes are inserted. The key process problems of stand ring welding deformation, sole plate assembly positioning, sole plate combining through hole processing cost, the production cycle and the like are solved through an auxiliary lower ring, the sole plate positioning templates and the positioning pipes, and the production cost and the production cycle are reduced. According to the stand ring manufactured through the technological method, the problems of assembly positioning, the production cost, welding deformation and the like are effectively solved, and construction site installation requirements are met; the subsequent production cycle and processing cost are greatly reduced, economy and practicability are both considered, and the purposes of lowering cost and improving effects are achieved.

Owner:HARBIN ELECTRIC MASCH CO LTD

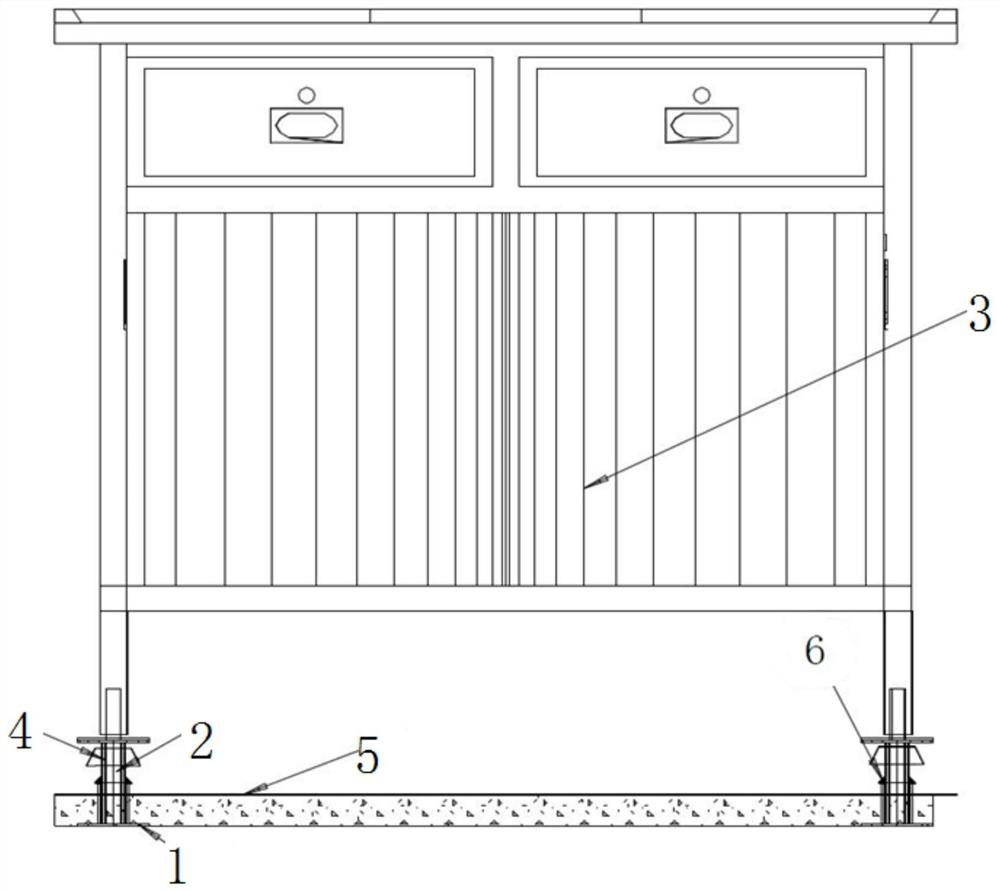

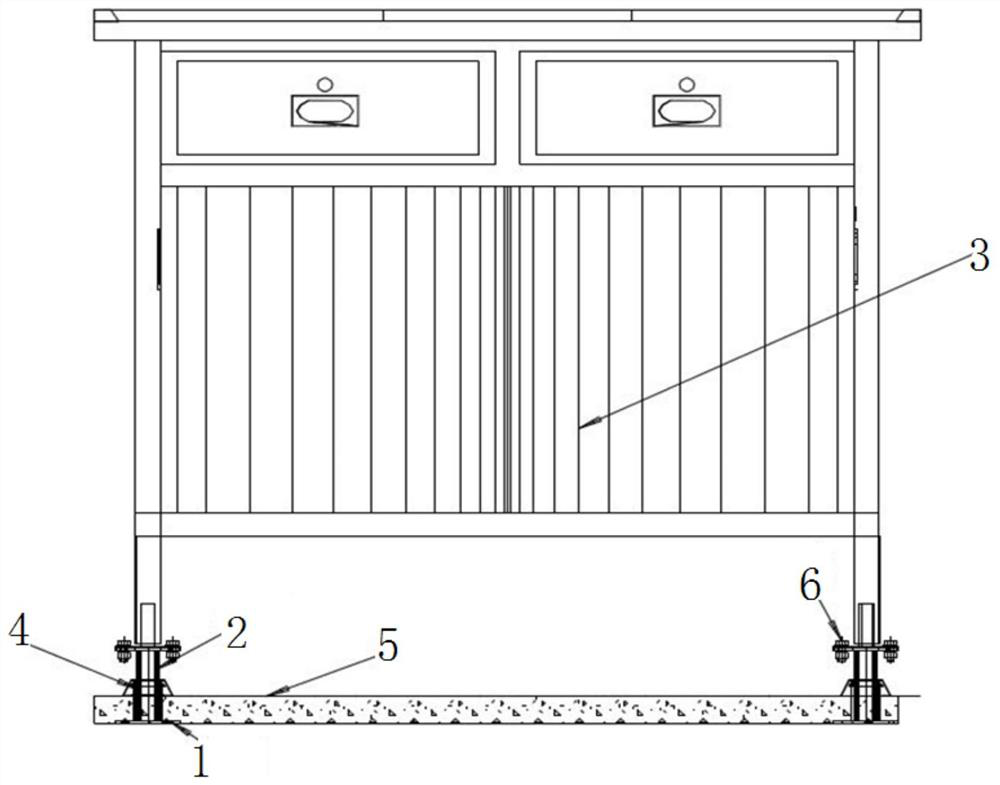

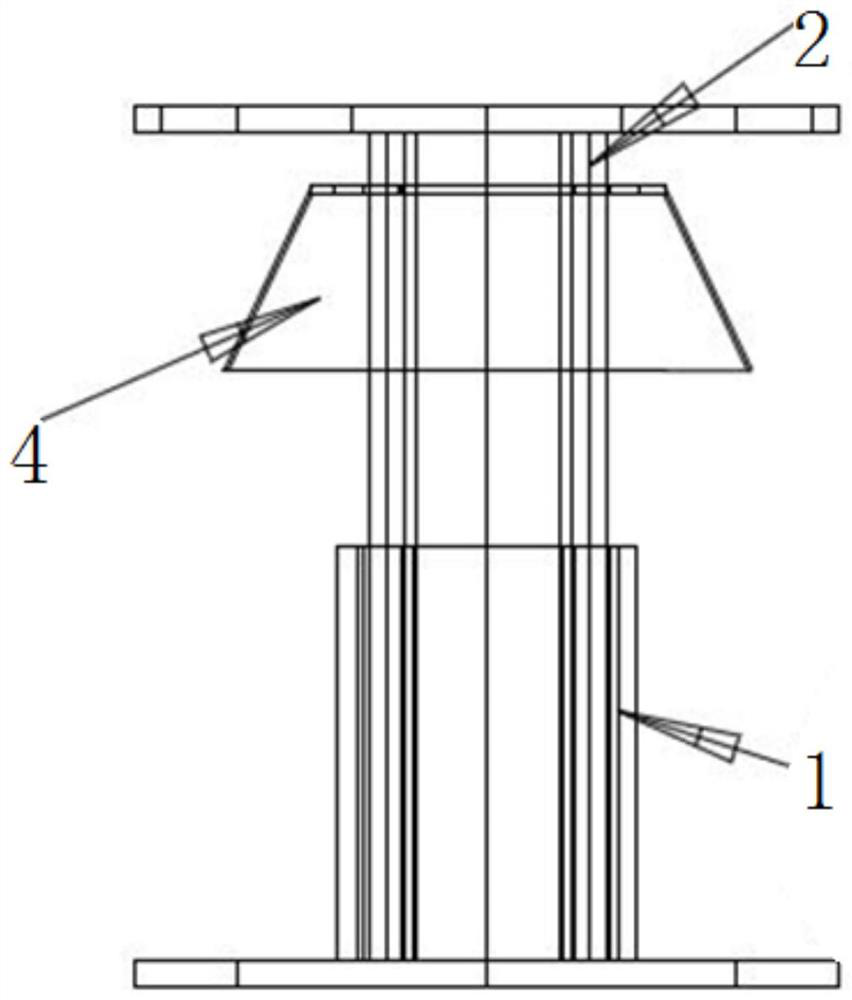

Detachable meal preparation furniture marine base

PendingCN111994211AReduce difficulty and accuracy errorsGuaranteed installation sizeCabin floor fasteningEnvironmental geologyStructural engineering

The invention discloses a detachable meal preparation furniture marine base which comprises a lower pin and upper pins. The lower pin is pre-buried in the ground of a ship; a bottom of each upper pinis arranged in a hollow pipe body of the lower pin in a sleeved mode, and the top of each upper pin is fixedly connected to the bottom of the meal preparation furniture; and the bottom of the meal preparation furniture comprises the plurality of upper pins, the tops of the upper pins are located in the same horizontal plane, and the upper pins and the lower pin are welded. In the invention, a pre-burying requirement of the equipment base can be met, and the requirements of equipment leveling, convenient disassembly and beautiful appearance can be met too.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

Novel whole moving device of drilling machine

InactiveCN104120980AThe installation position is accurateEven by forceDerricks/mastsDrilling machines and methodsPetroleumDrilling machines

The invention belongs to petroleum drill and exploitation equipment, and provides a novel whole moving device. A structure of three rows of tracks is adopted, two rows of main tracks are arranged below a drilling machine body, one row of auxiliary tracks is arranged below two slush pumps, connecting supporting rods are arranged among the three rows of tracks to ensure the accurate mounting position, rigid connecting frames are arranged on the drilling machine body and are connected with the two slush pumps respectively, and a connecting frame is arranged between the two slush pumps to ensure the distance between the slush pumps and even stress of the slush pumps in the moving process. When the drilling machine moves, two oil cylinders arranged on the back of the device push the drilling machine body, when the drilling machine body moves, moving force is transmitted to the two slush pumps through the rigid connecting frames, and therefore the aim that the whole drilling machine moves is achieved. According to the structural characteristics of the drilling machine, the three rows of tracks are adopted, and through the connecting frames and the track positioning supporting rods, the working condition that the whole drilling machine is pushed by the two oil cylinders to move is achieved. Mounting time is saved, and pushing and moving are safe and reliable.

Owner:BAOJI HONGXIN OILFIELD MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com