High-speed large-torque motor rotor structure and process of thermoelectric conversion system

A motor rotor, thermoelectric conversion technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, electromechanical devices, etc., can solve the problem of increasing the volume and weight of closed Brayton cycle power generation system, increasing the motor rotor Problems related to the difficulty of manufacturing and assembling the engine rotor, to ensure the overall installation size and dynamic balance requirements, improve the overall assembly accuracy, and prevent loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

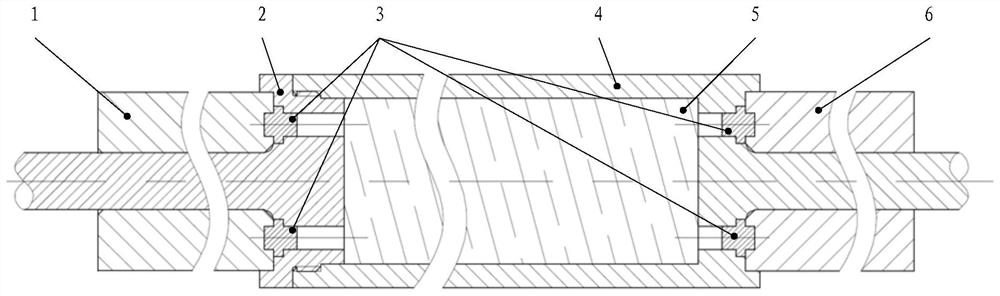

[0032] A high-speed, high-torque motor rotor structure for a thermoelectric conversion system, comprising an end cover shaft sleeve 1, an end cover shaft 2, a stop element 3, a sheath shaft 4, a magnetic core 5 and a sheath shaft sleeve 6.

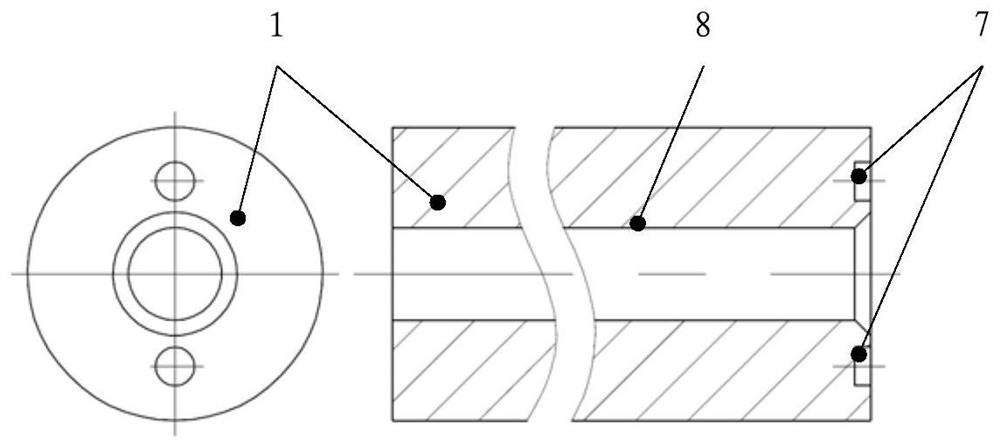

[0033] The outer side of the end cover shaft sleeve 1 has a cylindrical surface matched with the bearing, and one side end surface and the cylindrical surface of the end cover shaft sleeve 1 are matched with the annular groove 11 of the end cover shaft 2, and the end cover shaft sleeve 1 The end face matched with the annular groove 11 of the end cover shaft 2 is evenly distributed with blind holes 7 that are assembled with the cylindrical boss 16 on the stop element 3, and the center part of the end cover shaft sleeve 1 has a The through hole 8 fitted with the optical axis 10;

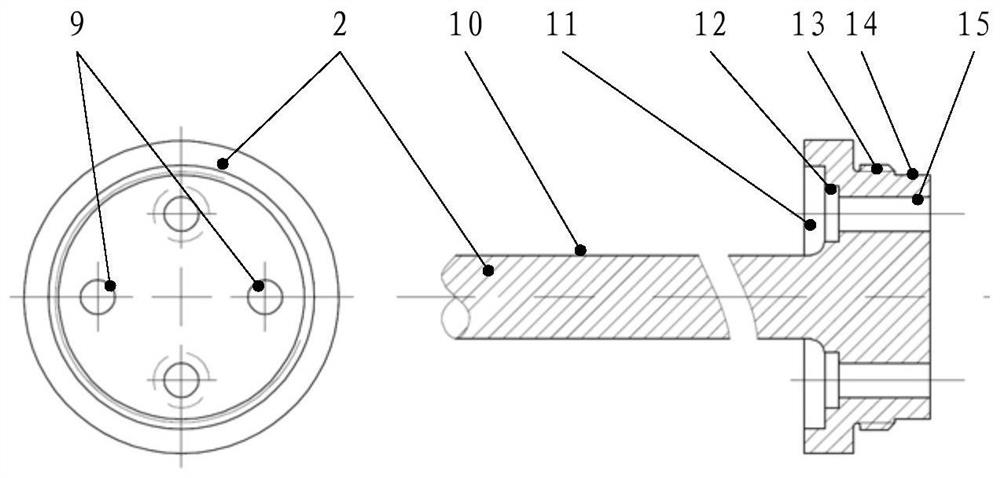

[0034] One side of the end cover shaft 2 has an annular groove 11 and an optical axis 10 assembled with the end cover shaft sleeve 1, and the other end surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com